In the semiconductor manufacturing field, isn’t the defect rate often a chronic concern that follows us like fate? In complex processes requiring high precision technology, determining which equipment will be the solution for our production line or if tangible results can be achieved despite significant initial investment costs often feels overwhelming. Making optimal choices amidst a flood of endless information and technical jargon is certainly not an easy task. Feeling these difficulties is entirely natural. Today, let’s track down a clear signpost on this complicated path to compile a wise solution that transforms defect rate concerns into high-quality production.

Chronic Problems in Semiconductor Production Processes and Huvics Solutions

Limitations and Issues of Manual Processes

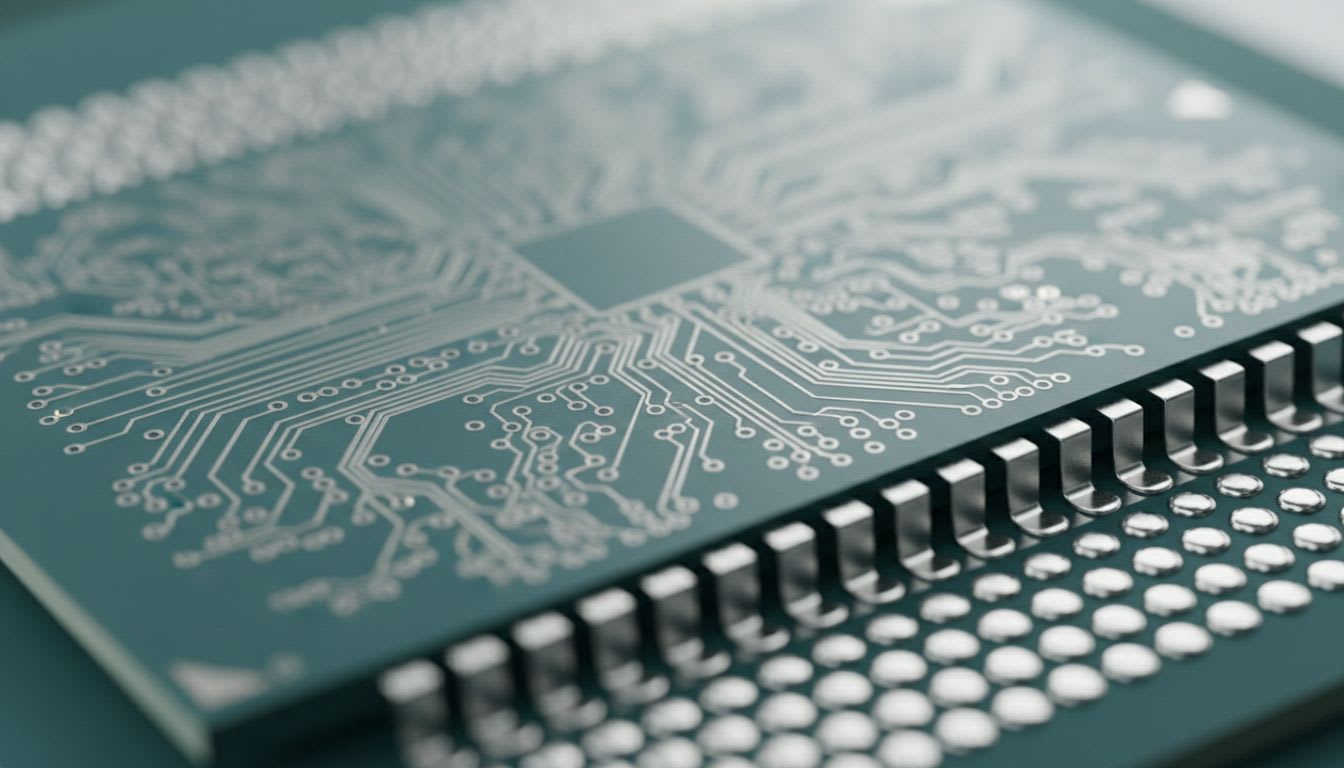

In semiconductor manufacturing, improving productivity and maintaining quality consistency have remained challenging puzzles for companies over the years. Especially, manual or semi-automatic processes, where results vary greatly depending on the worker’s skill level, have been the root cause of chronic problems. In critical processes like ultra-precision grinding or fine particle cleaning, where even the slightest error cannot be tolerated, these methods greatly reduce production quality consistency and, as a result, drastically increase defect rates, severely affecting overall production yield. In mass production systems, bottlenecks often occur due to decreased throughput and efficiency, deepening the concerns for companies. Just as a craftsman making a precision watch cannot cut parts with the same pressure and speed every time, methods relying on human hands and senses inherently have limitations.

Innovative Solutions of Huvics Advanced Equipment

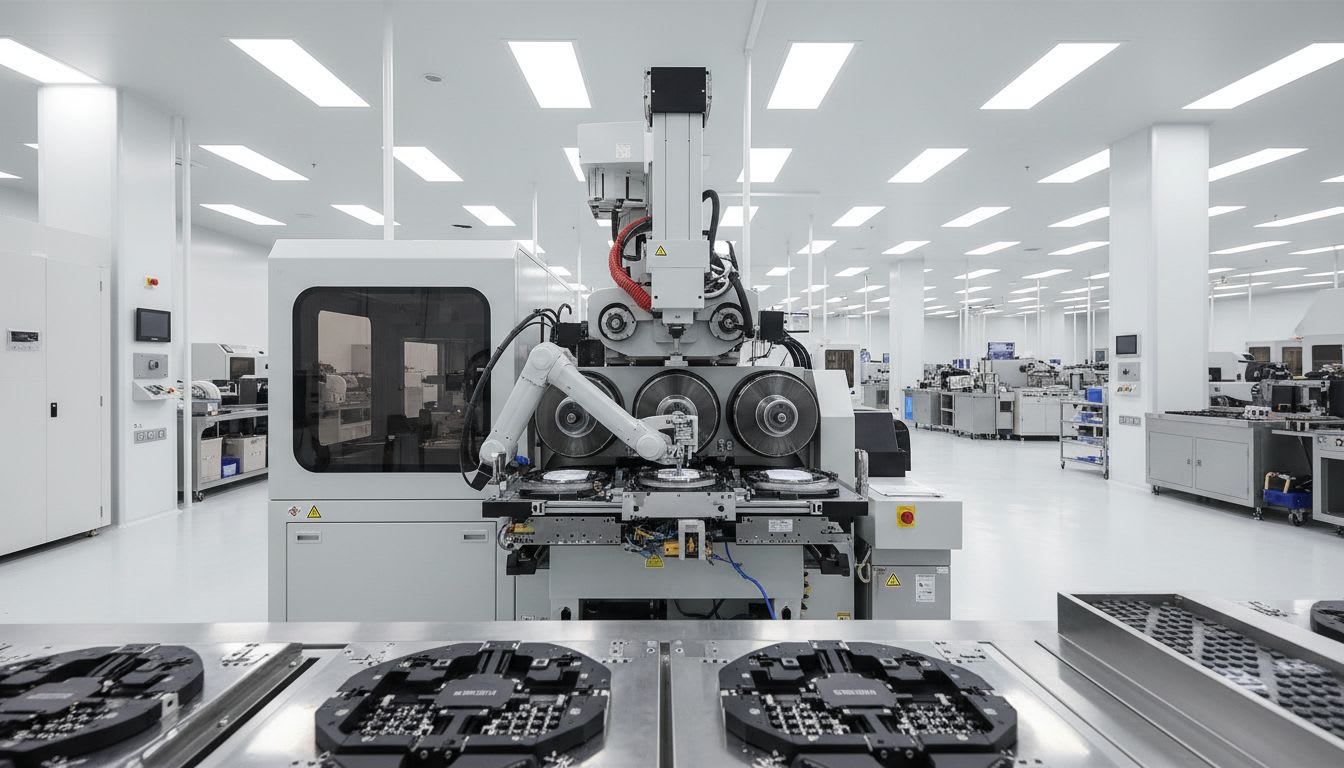

However, with Huvics, these limitations of traditional production methods can become relics of the past. Huvics’ advanced equipment clearly resolves the chronic problems of skill-dependent manual processes and brings an innovative wave of change across semiconductor production processes. For example, Huvics’ Grinder System and PKG Grinder go beyond simple material grinding. Besides being flexibly configurable in full auto and manual types, they ensure micron-level precision processing to the customer-required thickness, based on unique ultra-precision grinding technology. This ensures perfectly uniform and stable quality, independent of worker skill or condition, playing a decisive role in significantly reducing defect rates.

Solving Defect Rate Concerns with Huvics Advanced Equipment

Reaffirming the Inherent Problems of Manual Processes

As previously observed, the defect rate in semiconductor manufacturing has been a constant fate troubling manufacturers. In the past, where every microprocess had to be managed by human hands, even small errors directly correlated with product quality degradation, and it was almost impossible to maintain perfect consistency, no matter how skilled the workforce was. Fine defects occurring in micro grinding processes, more precise than a hair’s thickness and invisible to the naked eye, led to high defect rates, unnecessarily increasing production costs and causing major delivery delays. These challenges deepened as the semiconductor industry advanced, and traditional manual processes could no longer meet the exacting demands of rapidly changing markets. As if searching a complex modern city with only an old map, past methods were no longer able to illuminate the present way.

Innovative Alternatives of Huvics Equipment

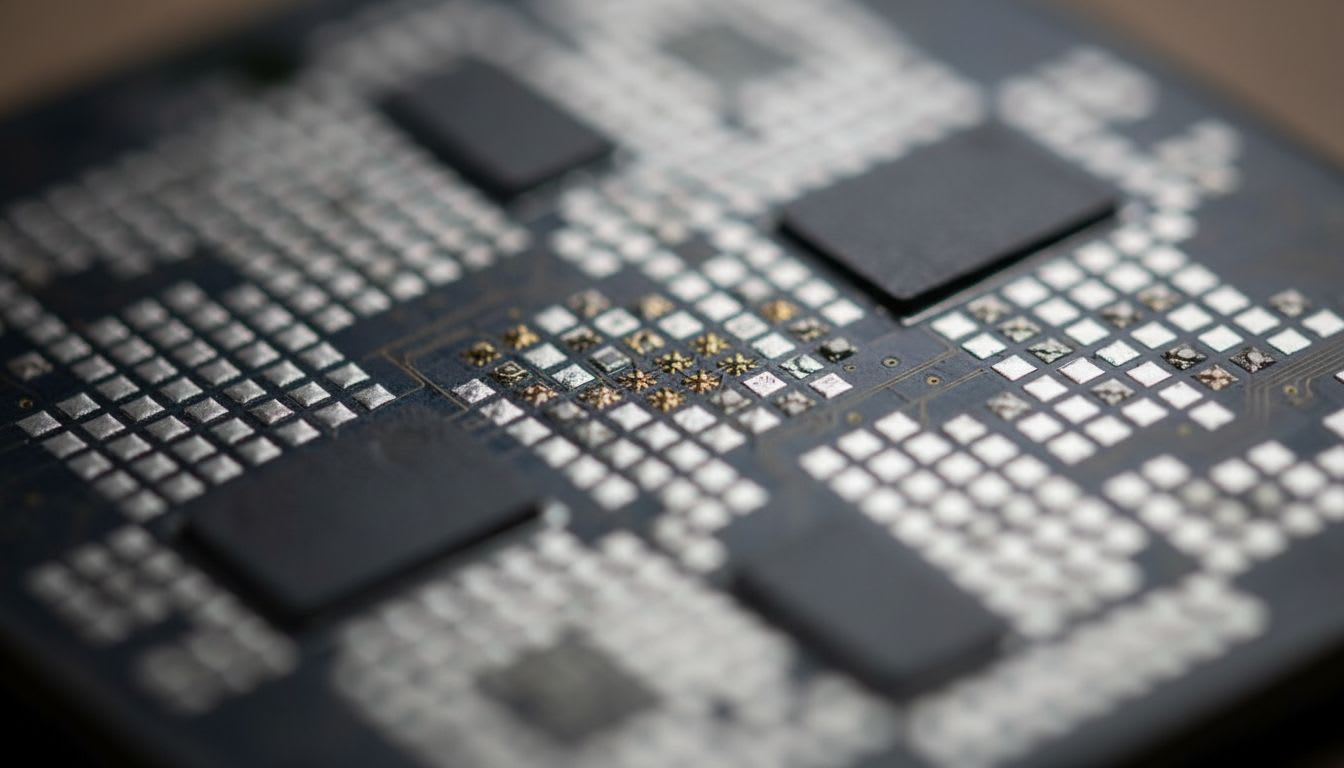

Now, however, Huvics’ latest semiconductor equipment perfectly overcomes these inherent limitations of manual processes and offers clear alternatives for revolutionary productivity. Huvics’ grinder system combines full auto and ultra-precision grinding technology to provide incredibly consistent quality in any environment. Furthermore, it allows flexible manual and automatic type selection suited to the characteristics of the production line, maximizing overall production line configuration efficiency. The cleaner machine also utilizes innovative multi-stage cleaning technologies like Micro Bubble, Water Jet, and Air Knife to seamlessly remove fine contaminants from product surfaces.

Details and Effects of Key Equipment

Optimized for various products like camera modules and sensors, the cleaning capability and perfect oven drying function ensure complete product quality stability. Additionally, the PKG Grinder utilizes a high-precision stage and a special diamond wheel to uniformly process various packages like FCBGA and WLCSP to the customer’s desired thickness with micron-level precision, achieving top-level precision regardless of product type. Huvics’ advanced equipment specialized for each process plays a decisive role in drastically reducing defect rates and maximizing high-quality stability. This is the future semiconductor production method Huvics proposes, elevating corporate competitiveness beyond defect rate concerns to reliable high-quality production.

Choosing Between Manual Processes and Automation Equipment from a Long-term Perspective

Strategic Perspective on Equipment Adoption

In the semiconductor production field, the journey towards high quality is inevitably faced with numerous worries and unforeseen challenges. Especially, companies considering new equipment adoption often get caught between the security of the long-familiar manual processes and the innovative potential brought by advanced automation. Yet, these two production methods show stark differences across various key metrics and act as critical decisive factors determining a company’s competitiveness from a long-term perspective. Deciding based solely on initial costs could lead to unexpected predicaments.

Hidden Costs and Limitations of Manual Processes

Although manual processes may seem advantageous with relatively low initial investment costs, they hide significant costs due to high dependence on skilled labor and continuously rising labor costs. Moreover, the varying skill levels and daily condition changes of workers hinder product quality consistency and lead directly to increased defect rates, ultimately significantly raising long-term operational costs. These factors translate into decreased productivity and unpredictable quality issues, eroding a company’s core growth drivers and reducing market adaptability.

Long-term Investment Value of Automation Equipment

Conversely, introducing Huvics’ advanced automation equipment may entail higher initial investment costs. However, it significantly reduces defect rates, visibly enhances productivity, and through long-term labor cost savings, offers a much higher long-term return on investment (ROI). For instance, Huvics’ cleaner machine, with innovative multi-stage cleaning technologies like Micro Bubble, Water Jet, and Air Knife, perfectly removes fine contaminants, dramatically lowering defect rates and ensuring complete product quality stability. This is not only an essential factor for high-quality semiconductor production but also acts as a key driver for increasing the company’s brand trust.

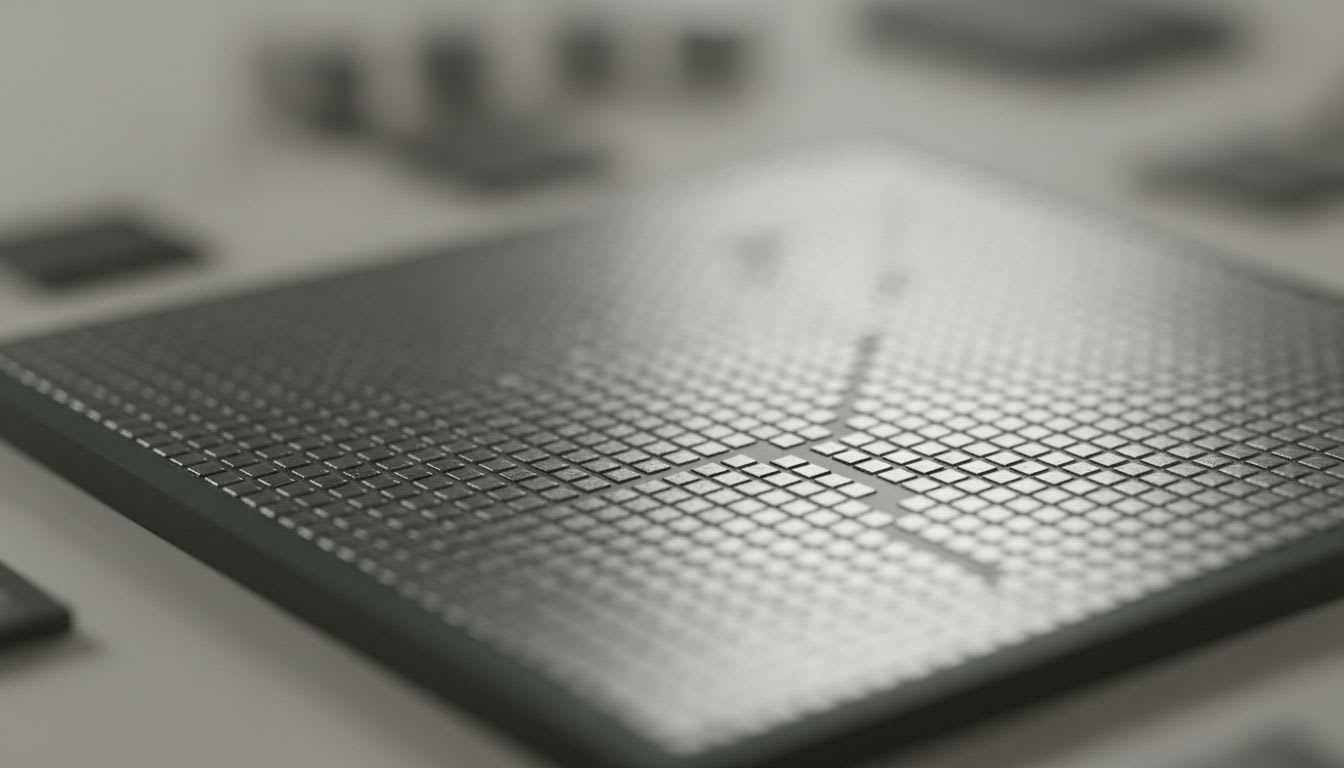

Precision and Uniformity of Huvics Equipment

Moreover, in terms of precision and uniformity, automation equipment guarantees results that manual processes cannot rival. Huvics’ PKG Grinder and Grinder System, utilizing ultra-precision grinding technology, high-precision stage, and diamond wheels, enable micron-level error-free processing. They process to the desired thickness with uniformity and precision, allow for flexible production line configurations, and ensure easy maintenance, securing production efficiency and quality stability simultaneously. Huvics’ ultimate goal and company vision is to solve chronic issues in the semiconductor industry and help our clients achieve sustainable high-quality production with these advanced solutions.

Achieving High-Quality Production with Huvics Customized Solutions

Importance of Strategic Equipment Adoption

Minimizing defect rates and ensuring final product quality stability in semiconductor production is a mission-critical task directly linked to corporate survival and a necessary condition for securing a competitive edge in the market. It is not just about keeping production lines running but about how precisely and efficiently products can be manufactured that dictates market competitiveness in today’s era. Under these circumstances, adopting semiconductor equipment transcends mere facility replacement to become a highly strategic choice that determines a company’s future. It’s akin to positioning key pieces in a chess game while anticipating several moves ahead.

Huvics offers a clear answer to the deep concerns of semiconductor manufacturers, valuing a thorough analysis of the problems encountered in current processes, the required precision, and the target production volume. Huvics’ solutions manifest genuine value at this point. With Grinder System and Cleaner Machine offering full auto and manual types, they maximize production line flexibility. This flexibility allows the selection of the most suitable automation solutions according to the specific situation, current investment capacity, and future growth goals of the client company. It prevents unnecessary overinvestment and enables focus on necessary areas.

Particularly based on Huvics’ unique ultra-precision grinding technology, the Grinder System realizes micron-level precision processing that does not tolerate fine errors. The PKG Grinder also processes various packages, like FCBGA and WLCSP, uniformly and precisely to the desired thickness, ensuring the highest quality level regardless of product type. Additionally, the Cleaner Machine eliminates invisible contamination particles on product surfaces using innovative multi-stage cleaning technologies like Micro Bubble, Water Jet, and Air Knife, and guarantees perfect drying with its complete Oven Dry function. This unique technology drastically enhances particle removal efficiency, leading directly to decreased defect rates and ensured final quality stability, directly improving production efficiency for our clients.

Key Summary

In conclusion, introducing semiconductor equipment is not just an expense but a wise evaluation of initial investment cost and long-term profitability to select the optimal automation solution that aligns with the company’s growth goals. Huvics contributes to our clients securing a firm position in rapidly changing markets and achieving continuous growth by reducing defect rates and ensuring final quality stability through high-quality production.

Proposal for the Future

It is time to move beyond past concerns and toward sustainable growth by meeting the highest production standards demanded by future markets.

Huvics is a high-tech company that develops and manufactures automation equipment and production systems across the semiconductor, LED, mobile, and cosmetic industries.

We support improving our customers’ productivity and securing quality competitiveness with top-notch personnel and continuous technological innovations.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com