According to industry expert analysis, ultrafine particles generated during high-precision grinding processes can increase the defect rate by up to 20%, posing a significant threat to quality stability. These minute impurities, invisible to the naked eye, directly impact the performance and lifespan of precision components, a challenge many companies are striving to address. How can we effectively control and perfectly eliminate these troublesome fine particles? Huvics offers a clear answer to this fundamental question.

Ultrafine Particles: A Critical Threat to Precision Component Quality

Grinding processes in precision component manufacturing are indispensable but also pose a significant challenge, primarily due to the ultrafine particles they generate. Although these tiny impurities are nearly impossible to detect visually, they subtly adhere to product surfaces, causing quality degradation and unexpected malfunctions. Standard cleaning methods struggle to completely remove these ultrafine particles, often resulting in serious defect rates.

Therefore, the key to the grinding process is not just precisely machining to the desired shape but also effectively controlling and entirely removing the generated fine particles. Huvics addresses this fundamental issue with innovative and integrated approaches and key technologies to resolve fine particle issues during grinding. This helps our clients achieve micron-level precision machining while significantly reducing defect rates and securing final product quality stability.

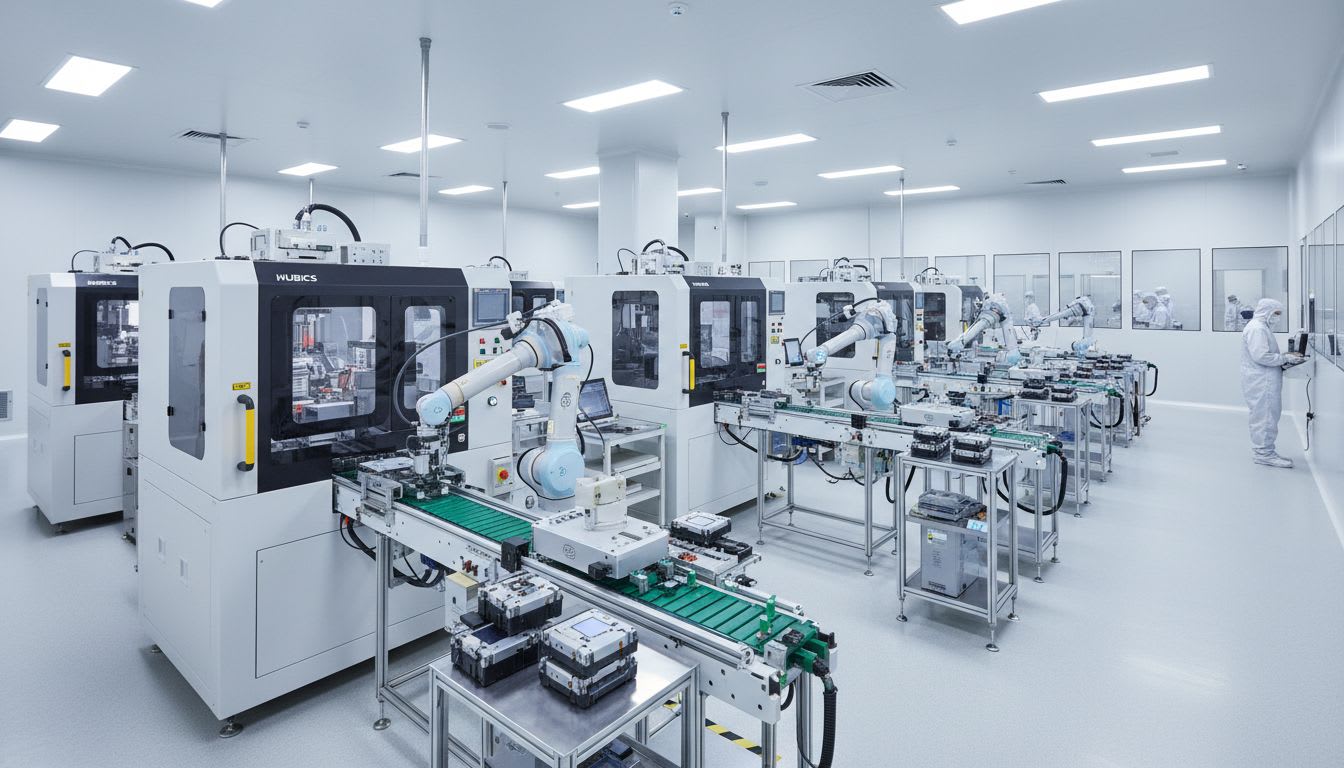

Huvics Grinder System: Minimizing Fine Particle Generation

Importance of Minimizing Fine Particle Generation

High-precision grinding processes are essential for producing high-quality products in modern advanced industries, yet the inevitably generated fine particles remain a perennial challenge. These fine particles do more than degrade the final product quality; they also hinder subsequent process efficiency and increase overall line defect rates. Huvics has recognized that the fundamental solution to this chronic fine particle problem starts with ‘minimizing the generation of particles themselves’. Our Grinder System focuses on realizing micron-level ultra-precision machining while effectively reducing the number and size of particles generated during the grinding process.

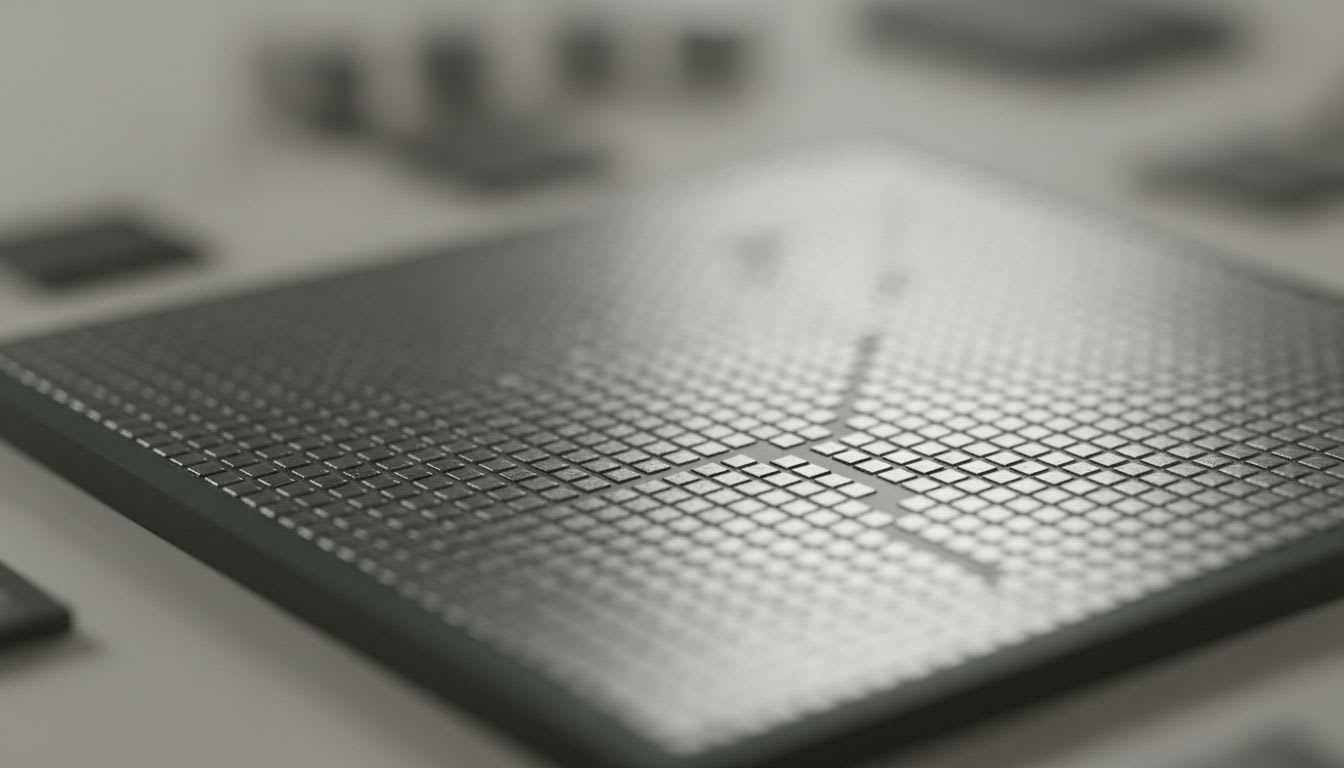

Precision Machining Technology of the PKG Grinder

Specifically, Huvics’ high-precision grinding equipment, the PKG Grinder, utilizes a high-precision stage and diamond wheel to uniformly and precisely machine various packages like FCBGA, WLCSP, QFN/DFN, and solar cells to the client’s required thickness. This technology plays a crucial role in ensuring unwavering quality stability from the initial stage by curbing fine particle generation from the start, beyond merely smoothing the product’s shape. Through this proactive approach, Huvics provides a robust foundation for clients to enhance productivity and enhance the reliability of their final products, securing a competitive edge in the market.

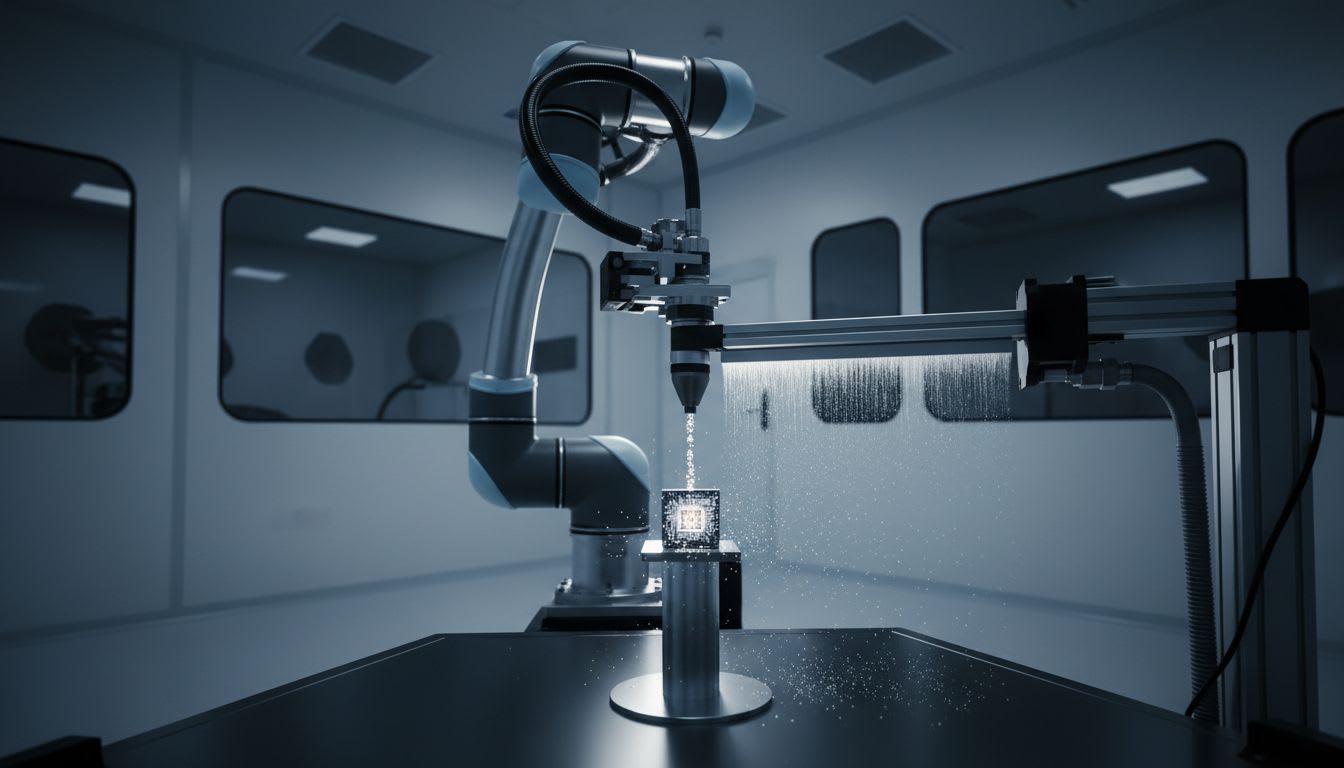

Cleaner Machine: Perfect Removal of Residual Ultrafine Particles

The Residual Particle Issue and Cleaner Machine

No matter how advanced grinding technology becomes to minimize fine particle generation, the reality is that some residual ultrafine particles remain post-process. These residual particles pose an even greater risk due to their invisible nature, critically affecting the function and lifespan of ultra-precision products if left unresolved, ultimately leading to defects. So how can these leftover ultrafine residual particles be completely removed, preserving the value of meticulously machined ultra-precision products for the market?

To solve this challenge, Huvics offers an innovative solution with the Cleaner Machine. This equipment extends beyond simple cleaning, focusing on meticulously removing residual particles that linger even after minimizing fine particle generation during grinding. The Cleaner Machine plays a vital role at this critical juncture that decides the final product quality, helping clients produce perfect products.

Multistep Cleaning and Complete Drying Technology

For the perfect removal of residual ultrafine particles, Huvics’ Cleaner Machine integrates cutting-edge multistep cleaning technologies such as Micro Bubble, Water Jet, and Air Knife. This system effectively separates and eliminates minute contamination particles adhering to surfaces of various ultra-precision products like camera modules, sensors, VCM motors, and trays, leaving no trace behind. Furthermore, post-cleaning, the Oven Dry function ensures that no moisture traces remain, completely preventing the possibility of secondary contamination from residues. This comprehensive cleaning process by Huvics thoroughly eliminates even invisible ultrafine particles, maximizing the reliability of the final product and assisting clients in securing an exceptional competitive advantage in markets demanding the highest precision.

Differentiated Value of Huvics Integrated Solution

Necessity of Integrated Solution

Although high-precision grinding processes are essential elements of modern advanced industries, the fine particle issue generated during processing remains a serious task, leading to product quality degradation and increased defect rates. These fine particles can penetrate the minute structures of precision components, potentially critically affecting their function and lifespan, making perfect control technology a necessity rather than an option. If the fine particle issue is not resolved, fabulous technology may still fail to maintain competitiveness in the market.

Core Technology Composition

To solve this challenge, Huvics offers an integrated solution combining high-precision grinding technology with innovative multistep cleaning technology. This system goes beyond mere particle removal, encompassing core technologies such as:

- Minimizing fine particle generation with micron-level precision machining using the PKG Grinder.

- Meticulously removing residual contamination particles with the multistep cleaning technology of the Cleaner Machine.

- Guaranteeing complete final drying with no moisture traces using the Oven Dry function.

Expected Effects and Applications

As a result, clients can dramatically improve particle removal efficiency, significantly reduce product defect rates, and firmly secure final product quality stability. It is especially optimized for cleaning various sensitive precision components such as camera modules, sensors, and VCM motors, offering consistent and reliable performance even in demanding manufacturing environments.

System Flexibility and Productivity Enhancement

Moreover, both the Grinder System and Cleaner Machine offer a flexible system configuration that allows choosing between Full Auto and Manual types, providing process automation and easy maintenance, contributing to maximizing productivity. This advanced integrated solution from Huvics is a crucial driving force for clients to secure unparalleled competitiveness in precision component manufacturing fields and ultimately enhance customer satisfaction. Huvics will be a reliable partner offering complete answers to the fine particle challenge, supporting clients’ successful business and innovative future.

Given that the defect rate and quality degradation due to fine particles in high-precision grinding processes remain a major task of modern industries, a fundamental approach to solving this is now a necessity rather than an option. Huvics provides an integrated solution by combining high-precision grinding technology minimizing fine particle generation with innovative multistep cleaning technology that perfectly removes residual particles. This enables clients to significantly lower defect rates and securely ensure the reliability of the final product, going beyond micron-level precision machining. Huvics will continue to stand as a robust partner, enabling clients to secure a dominant competitive edge in markets requiring the highest precision and ultimately leading to successful business ventures.

Huvics is a high-tech company that develops and manufactures automation equipment and production systems across the semiconductor, LED, mobile, and cosmetic industries.

With the best talent and continuous technological innovation, we support enhancing customer productivity and securing quality competitiveness.

Huvics inquiry contact

Phone: 031-374-8285

Email: cdpark@huvics.com