According to recent trends in the semiconductor industry, an increase of just 1% in defect rates in more miniaturized processes can cause losses amounting to billions. This issue goes beyond simply reducing production volume, posing a significant threat to the overall efficiency of complex manufacturing lines and product reliability. The modern semiconductor manufacturing field is facing the tremendous wave of endless miniaturization and increased complexity, with defect rate management, once unimaginable in the past, now becoming the biggest challenge. It has reached a point where existing equipment can no longer ensure stable yield, leading to a grave situation that threatens not only productivity but also the reliability of the final product. Thus, solving these challenges and securing stable yields have become urgent tasks for all semiconductor manufacturers, making the introduction of new equipment for building next-generation semiconductor production lines—requiring high precision and perfect cleanliness—not just an option but a necessity. At this juncture, Huvics is opening new horizons in semiconductor production by addressing chronic defect rate issues with innovative equipment solutions.

Precision Grinding Technology-Based Innovation by Grinder System

Micron-Level Precision Machining Technology

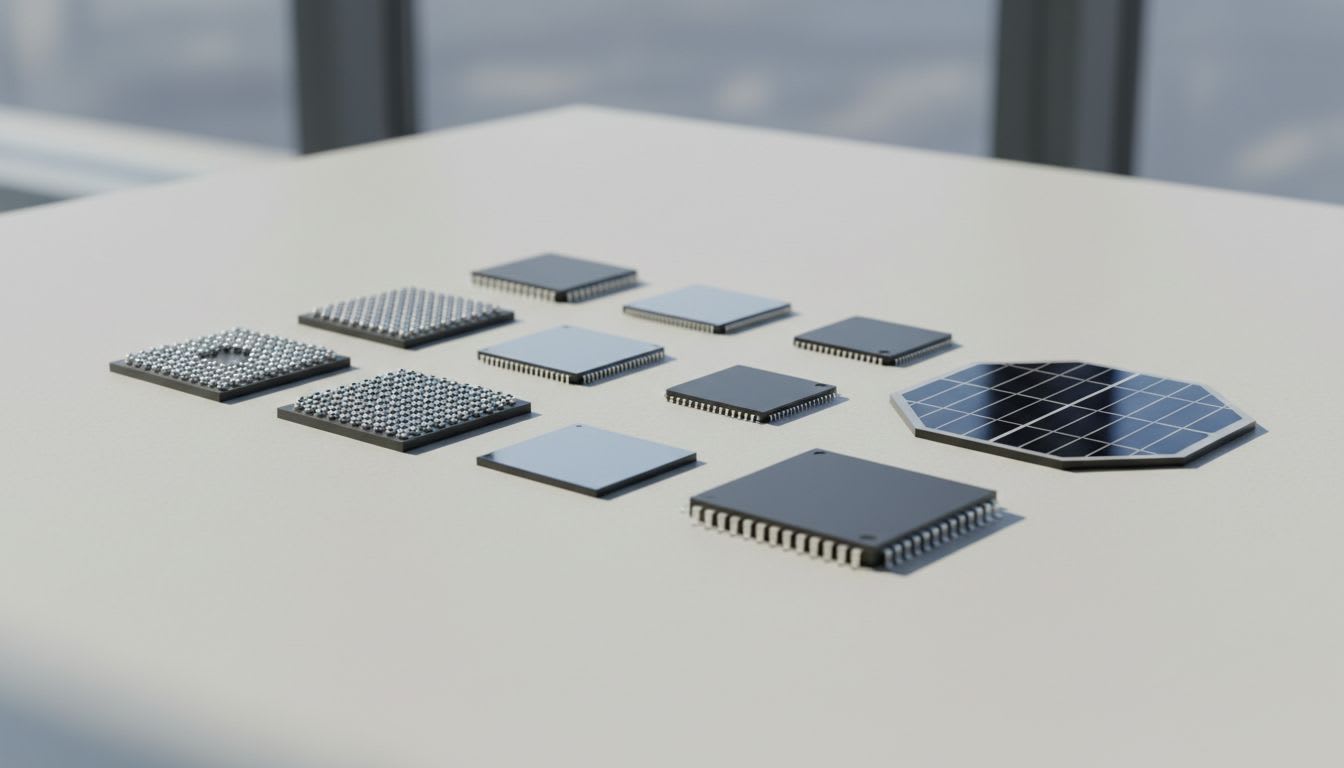

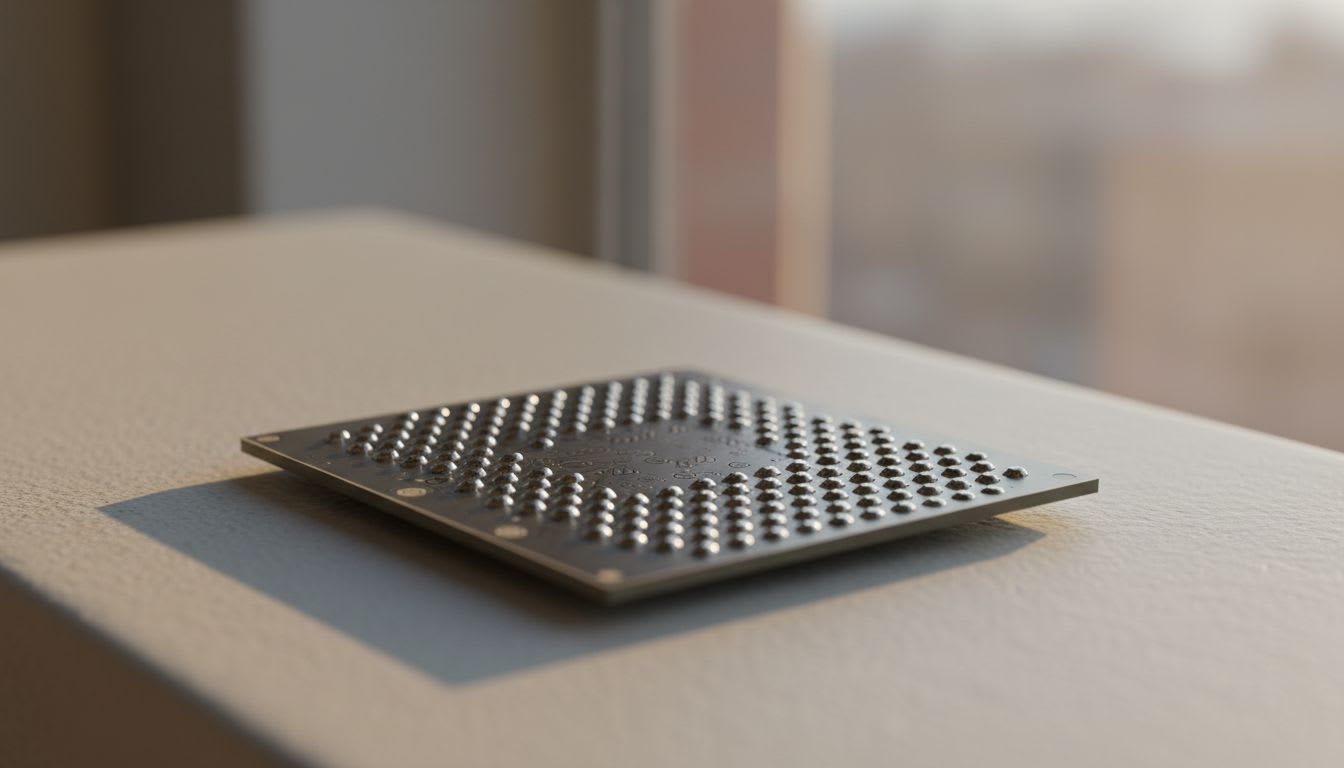

Huvics’s core solution, the precision grinding technology-based Grinder System and PKG Grinder, is at the forefront of change. These machines handle wafers or packages with a precision that does not tolerate even micron-level errors. By processing various packages such as FCBGA, WLCSP, QFN/DFN, and Solar Cells to perfectly uniform and precise specific thicknesses as required by customers, they play a crucial role in fundamentally blocking the possibility of physical defects that can occur in fine processes and securing stable yields.

The core of semiconductor production lies in error-free precision and unchanging perfection. Micron-level slight thickness variations often lead to critical defects affecting productivity and profitability. Huvics deeply understands these field difficulties and presents solutions with its precision grinding technology-based grinder system and PKG grinder. In fact, after adopting the Huvics system, one major semiconductor manufacturer noticeably improved the defect rate caused by slight thickness variations in the FCBGA package process, elevating production efficiency to a new level.

Flexible Production Line Configuration and Response

Furthermore, the flexible production line configuration ability of Huvics equipment provides optimized solutions for diverse production environments. By selectively combining fully automated Full Auto types with Manual types that require detailed control by skilled operators, it actively responds to changing production demands and technological advancements. This provides a solid foundation that perfectly complies with product specifications even in the precision processing of complex packages, strengthening the market competitiveness of client companies.

Perfect Contamination Removal with Advanced Cleaner Machines

The Threat of Fine Contamination and Need for Solutions

Particles or contaminants that may finely remain after micron-level precise grinding processes often result in critical defects in the final product quality. If invisible contaminations remain, no matter how precisely processed, the efforts can be in vain. This ‘invisible threat’ was one of the most challenging obstacles in managing defect rates in semiconductor manufacturing. Huvics took a deep interest in this issue and developed an innovative cleaner machine solution that uproots contamination, going beyond just wiping away, introducing it to the field.

Multi-Stage Cleaning Technology and Quality Stability

Huvics’s cleaner machine showcases the essence of advanced multi-stage cleaning technology. By integrating micro-bubble, powerful waterjet, and precise air knife technologies, it leaves no room for fine contamination particles sticking to product surfaces. It provides optimized cleaning protocols considering the properties of sensitive high-value-added components like camera modules and sensors, adding an oven dry function to completely block the possibility of secondary contamination occurring in the final drying process. In fact, many customers have seen a noticeable reduction in defect rates due to fine contamination, significantly improving quality stability and production efficiency after adopting the cleaner machine.

Successful Field Case Studies of Huvics Solutions

In semiconductor production fields, defect rate management is becoming increasingly important with the complication of micro-processes. Amidst this backdrop, Huvics has drastically reduced defect rates through innovative equipment solutions across numerous fields, achieving stable target yields, and leading a successful transformation. Now we’ll specifically explore three key field cases showing how Huvics’s advanced equipment presents new standards for semiconductor manufacturing, from micron-level precision machining to perfect multi-stage cleaning.

- Significantly reduced defect rates and improved product reliability in precision package processing with PKG Grinder.

- Notably lowered defect rates in wafer and product cleaning sites by removing fine contamination particles with Cleaner Machine adoption.

- Established flexible production lines and achieved stable target yields by integrating the operation of grinders and cleaner machines.

Facing the massive wave of precision and complexity deepening, the defect rate issue in semiconductor manufacturing fields has become an essential task that can no longer be overlooked. Today, we could confirm through three cases how Huvics’s advanced equipment has drastically reduced defect rates and secured stable yields in the field, from micron-level precision processing to perfect multi-stage cleaning. This goes beyond just increasing efficiency to fundamentally strengthen the reliability of semiconductor production, becoming an important indicator determining future competitiveness. Huvics’s technological evolution, as such, will open new horizons for the semiconductor industry through visible outcomes.

Huvics is an advanced technology company that develops and manufactures automation equipment and production systems across industries such as semiconductors, LED, mobile, and cosmetics.

We support our customers’ productivity enhancement and quality competitiveness through top-tier talent and continuous technological innovation.

Contact Huvics

Phone: 031-374-8285

Email: cdpark@huvics.com