Semiconductor Yield Decline Starts from Unseen Places

The importance of the semiconductor packaging process cannot be overstated. However, are you overlooking the yield decline problem arising from slight performance differences in equipment? Though it’s not immediately visible, it can lead to increased defect rates, causing significant time and cost losses. If this situation persists, it may affect the overall competitiveness of your company.

Process Innovation Case Achieved by Replacing Laminator Systems

In the field of semiconductor packaging, production efficiency and yield translate directly to competitiveness. Recently, a company made significant achievements by enhancing production efficiency through replacing their laminator system. This is akin to a skilled chef using a new sharp knife instead of a dull one to cook more swiftly and accurately. The limits of existing equipment’s performance were blocking the full potential of skilled technicians. Introducing a new laminator system breathed new life into the production line. Formerly time-intensive tasks could now be completed in one precise process. This change not only reduced time but also increased precision and decreased defect rates.

The low productivity and frequent errors of old laminator systems are challenges faced by many companies. Especially in multi-step processes, these issues are a major cause of decreased productivity. However, replacing with the latest laminator systems can greatly improve the situation. Just like replacing an old car with a new high-performance model, it promises innovative changes that enhance the entire production line’s flow and unlock its potential.

Key Improvements of Laminator Systems

- Establishing a One-Stop process from Expander to UV Curing

- Flexible production line response with Semi Auto and Manual options

- Enhanced bonding strength and process stability with Lamp/LED UV Curing systems

The changes brought by high-performance laminator systems to the production site are noteworthy. This goes beyond merely replacing equipment and signifies a leap in production efficiency. It’s like replacing old plumbing to ensure smooth water flow. The low productivity caused by inefficient processes of existing equipment can be significantly improved through process automation, reduced Tact Time, and decreased defect rates. Particularly, automation systems play a crucial role in enhancing overall operational efficiency, helping companies maximize productivity.

Wise Investment for Yield Improvement

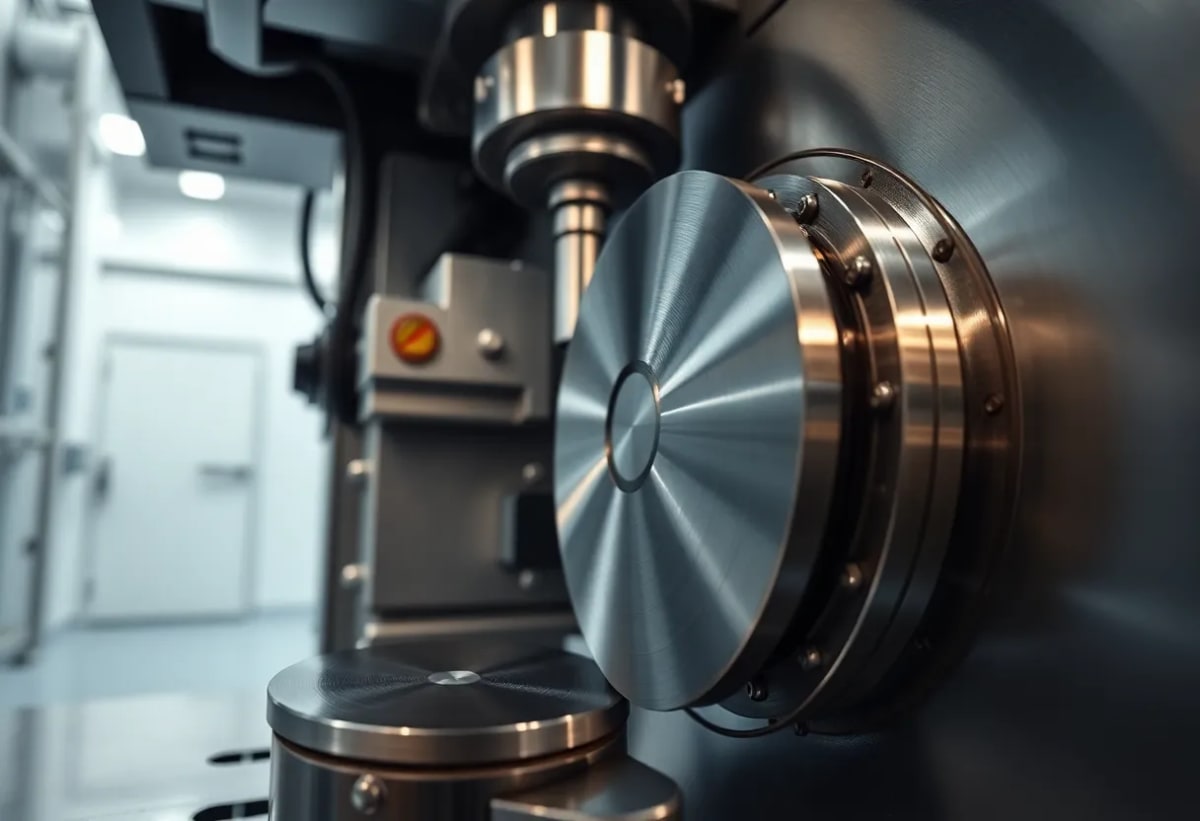

Upgrading to high-performance equipment is not merely an expenditure but an essential investment for improving yield. The Grinder System, through high-precision grinding technology, controls minute irregularities on grinding surfaces, aiding in achieving the dual goals of reducing defect rates and enhancing productivity. With the undeniable importance of equipment systems, why not enhance your entire process’s competitiveness with Huvics?

Huvics is a cutting-edge technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support clients in enhancing productivity and securing quality competitiveness through top-notch personnel and continuous technological innovation.

(Huvics) Contact Information

Phone: 031-374-8285

Email: huvics01@gmail.com