What if a long-standing problem of chronic productivity decline and uneven quality could find a dramatic turning point just with the introduction of an advanced precision grinding and cleaning system? If this is not just a mere imagination but an actual transformation observed in the field, it would provide hope for unsurpassed efficiency and growth for your company. Today, we will delve into the secret behind the astonishing changes witnessed through Huvics’ grinder system implementation, which has addressed the trials of a precision parts manufacturer and increased monthly production by 30%.

Challenges of Precision Parts Manufacturers and Huvics Solutions

Challenges Faced by Precision Parts Manufacturer

A certain precision parts manufacturer had been dealing with persistent issues of productivity degradation and quality inconsistency for several years. Especially in core component production lines where micron-level precision machining was essential, hitting the monthly production target was challenging due to low yield, leading to frequent delivery delays and customer dissatisfaction that eroded trust in the company. There were evident limitations with existing equipment in processing fine surfaces and contaminant removal, resulting in soaring defect rates that continued to increase production costs. To break this vicious cycle and secure competitiveness, the company actively sought innovative changes with a new ultra-precision grinding and cleaning system aimed not merely at equipment replacement but resolving fundamental production issues and achieving sustainable growth.

Advanced Precision Grinding and Cleaning Solution from Huvics

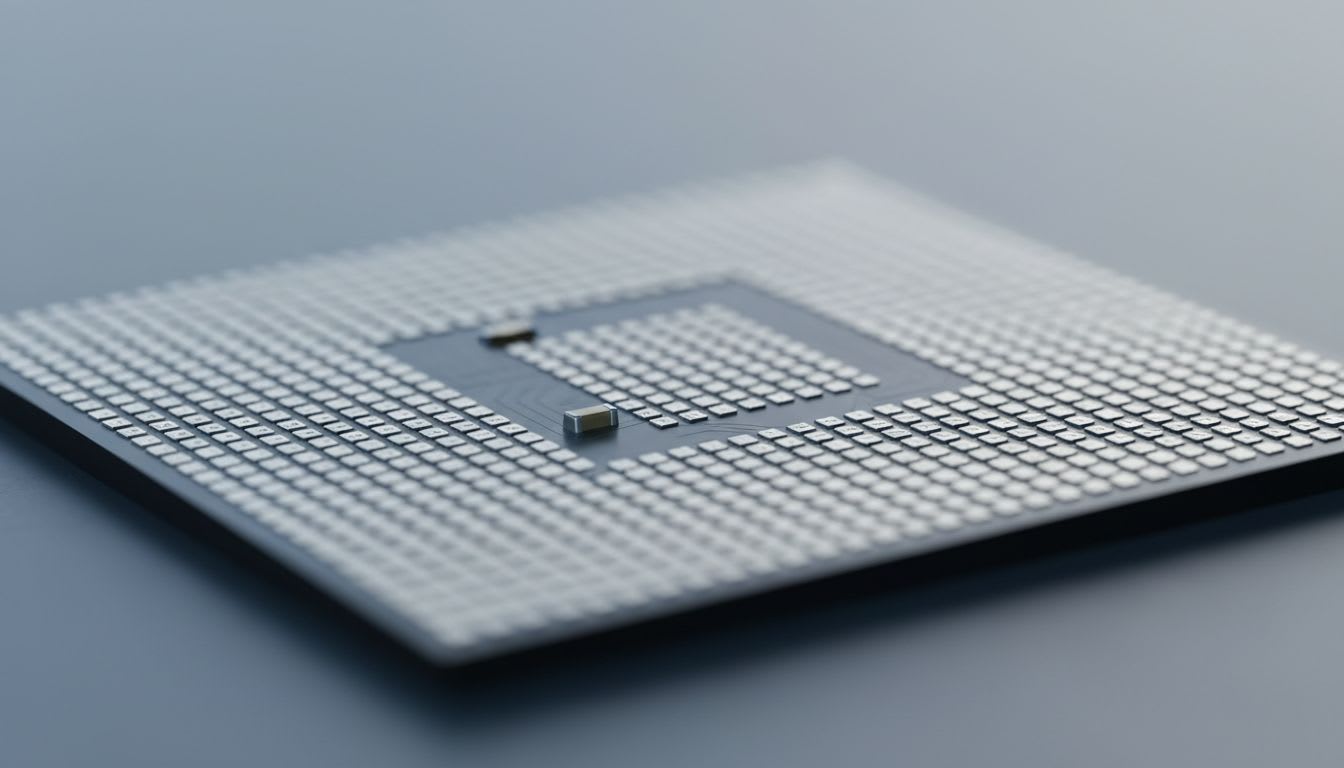

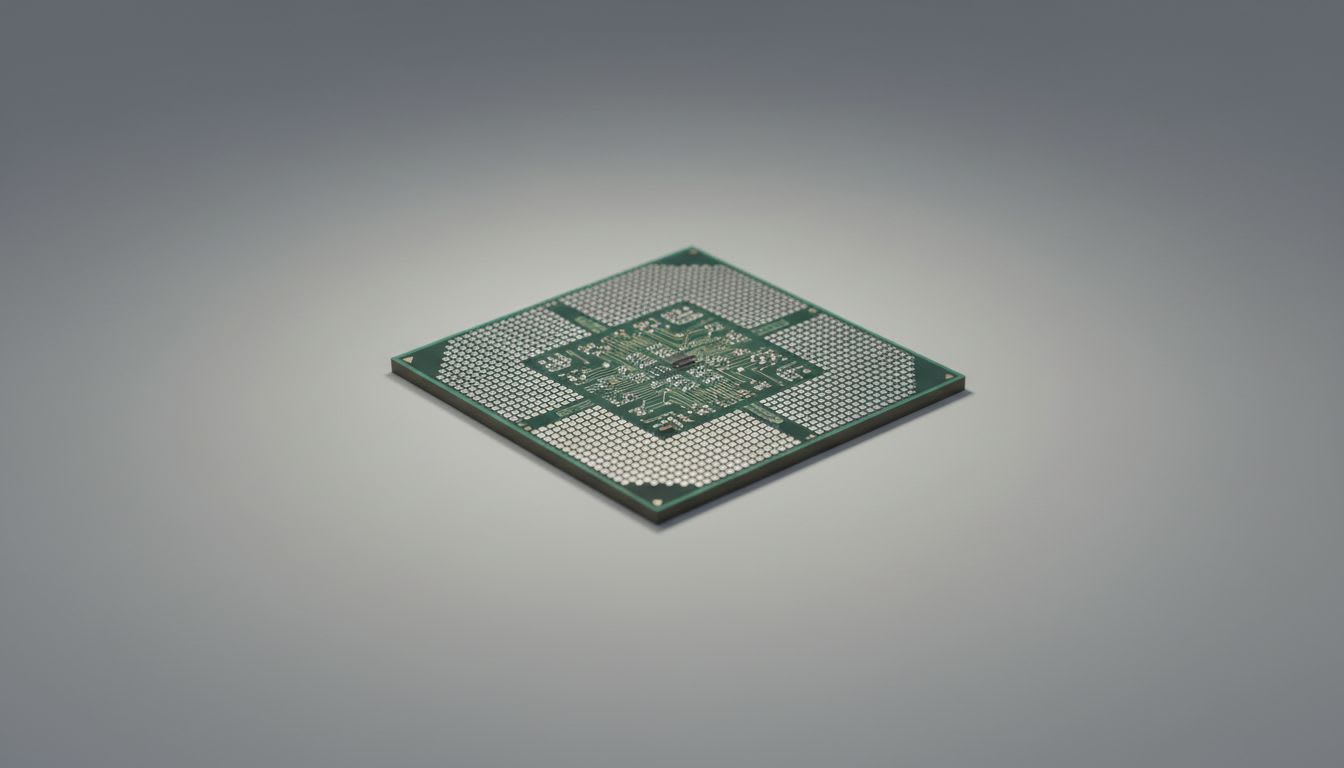

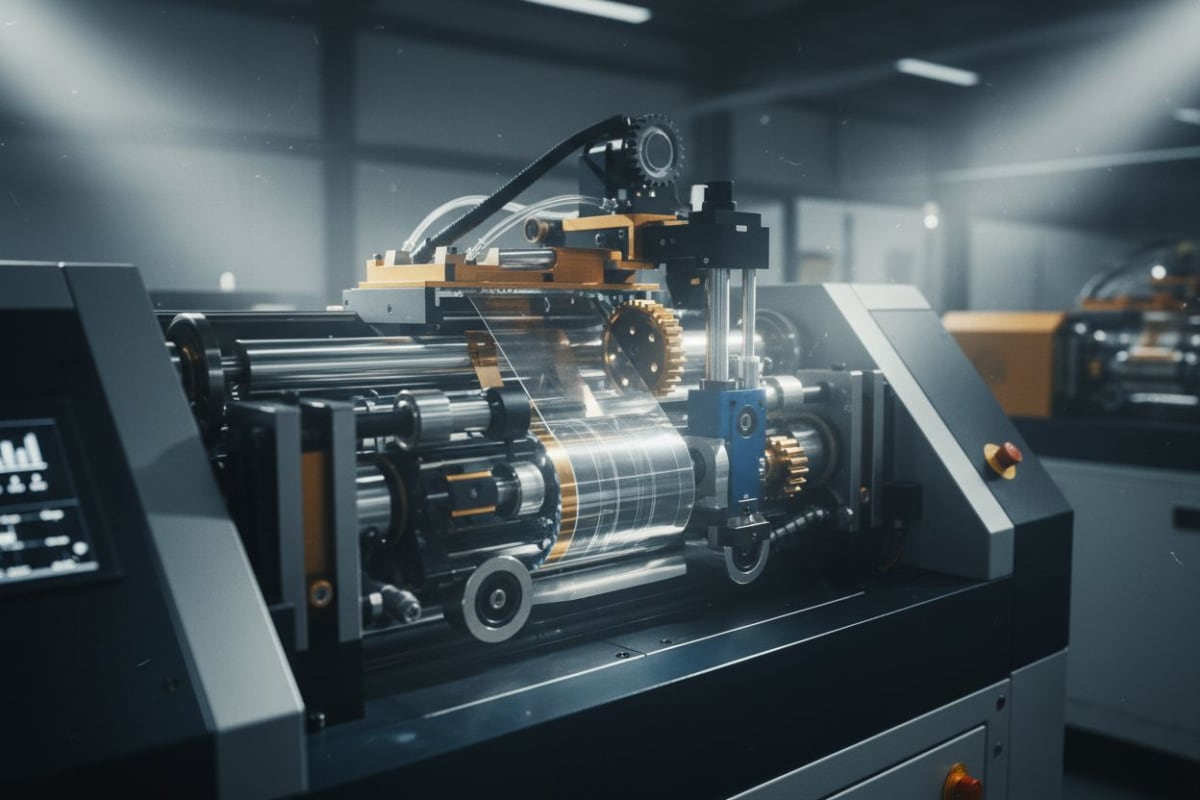

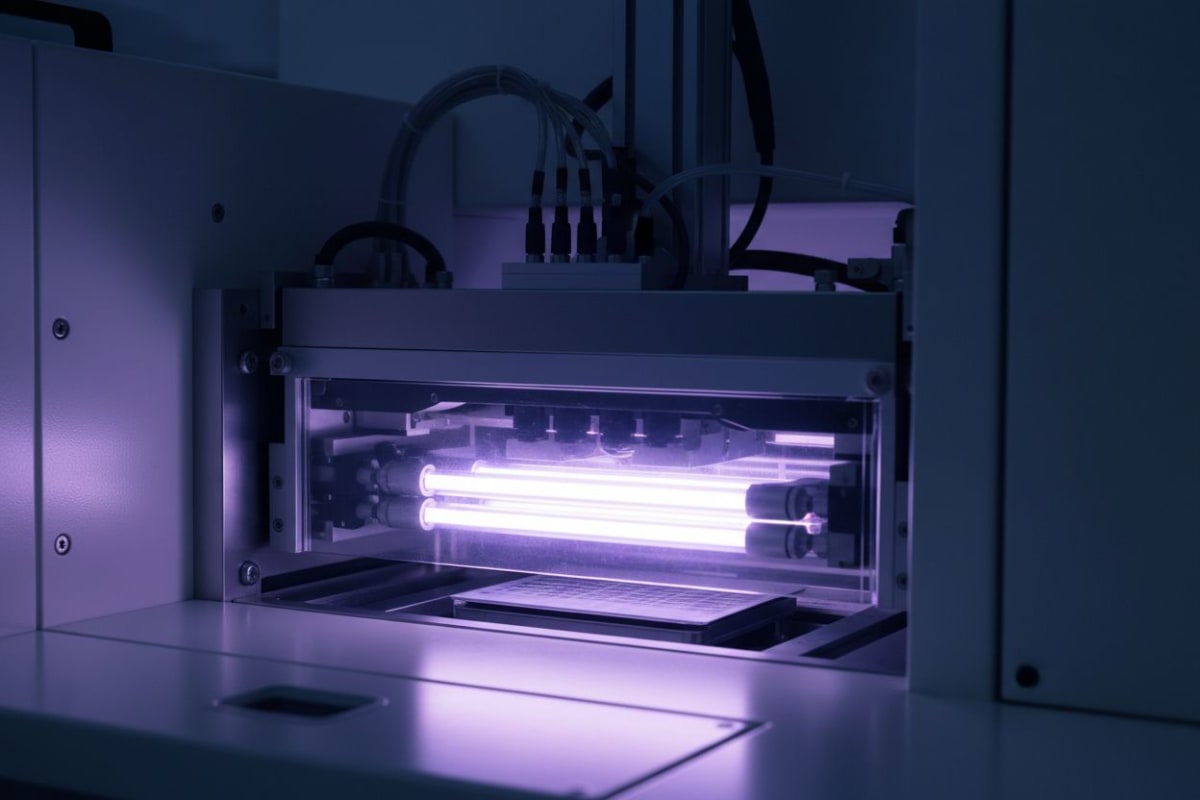

In this critical situation, Huvics provided a sophisticated precision solution playing a pivotal role. Huvics’ PKG grinder system accurately implemented micron-level precision processing as required by clients, supported by advanced precision grinding technology. It processed various package types like FCBGA, WLCSP, QFN/DFN, Solar Cell, etc., uniformly and subtly, ensuring consistent quality even with difficult processing. Additionally, Huvics’ cleaner machine effectively employed multistage cleaning technology using microbubbles, water jets, and air knives to completely remove micro-contaminants from product surfaces. Optimized for cleaning precision parts like camera modules, sensors, and VCM motors, this system further maximized final quality stability with its Oven Dry function, promising perfect drying processes. Flexible system configurations that allowed Full Auto and Manual selections adapted to production line characteristics and started proving their value on-site.

Innovative Achievements from Huvics System Implementation

30% Increase in Monthly Production and Quality Enhancement

The introduction of Huvics’ solution brought about dramatic changes beyond expectations. High-precision grinding and impeccable multistage cleaning processes significantly reduced defect rates, translating directly into a substantial improvement in production yield. Achieving a level of precision and quality consistency that seemed unattainable with previous equipment, the manufacturer achieved the impressive feat of increasing monthly production by 30%. No longer did customer complaints arise due to delivery delays, and instead, heightened quality reliability became a catalyst for generating new business opportunities. This case distinctly demonstrates that Huvics’ philosophy of not merely selling equipment but solving fundamental production issues and aiming for sustainable growth for clients is translated into tangible value. With pioneering technology, Huvics is setting a new benchmark for precision manufacturing, concentrating efforts on equipping clients with unmatched competitiveness in the market.

Strategic Background for System Implementation

As mentioned earlier, improving productivity and quality stability are core challenges for advanced manufacturing companies. Particularly facing the limits of traditional methods in the high-precision parts sector involving complex and minute processes, the manufacturer deliberated on innovative equipment introduction targeting increased production and product quality advancement. After extensively reviewing countless alternatives in the market, they made a critical strategic decision to implement Huvics’ PKG grinder system, based on ultra-precision grinding technology, and a cleaner machine utilizing multistage cleaning technology. This was more than mere equipment introduction— it was a strategic investment to secure future competitiveness.

PKG Grinder’s Ultra-Precision Machining Technology

Huvics’ PKG grinder system was designed for flexible use, whether in Full Auto or Manual type, allowing for easy integration with existing production lines and enabling adaptive, efficient production line configurations tailored to on-site environments. Above all, the system boasted the capability of executing extreme precision machining at micron levels. It proved strong competitiveness by processing challenging packages like FCBGA, WLCSP, QFN/DFN, and Solar Cell precisely and uniformly to the thickness specified by the client. This excellent capability drastically reduced defect rates and maximized processing precision, fundamentally improving production efficiency and making this delicate and precise machining a pivotal factor in determining the initial product quality.

Cleaner Machine’s Multistage Cleaning Solution

Along with PKG grinders, Huvics’ cleaner machine was introduced to secure perfect cleanliness, a core factor of final product quality. This system thoroughly removed micro-contaminants from surfaces of various precision products like camera modules, sensors, and VCM motors through its proprietary multistage cleaning technology utilizing microbubbles, water jets, and air knives. Equip with an Oven Dry function for perfect drying processes, it fundamentally prevented quality degradation due to leftover contaminants or moisture post-cleaning. Such integrated cleaning solutions played a crucial role beyond mere contaminant removal, extending product reliability and lifespan while elevating client value one notch higher. Near-perfect cleanliness made a decisive contribution to increasing customer satisfaction.

Customer-Centric Partnership and Sustainable Growth Motivation

Collaborative Approach and Achievements with the Customer

To minimize trial and error during the initial system setup process, Huvics went beyond merely being an equipment supplier, closely collaborating with clients to optimize systems to align with production environments. This amalgamation of brilliant technology and customer-centric partnership resulted in astounding achievements, such as increasing the monthly production by a remarkable 30% post-system introduction as previously mentioned. This clearly demonstrates that Huvics has crucially contributed to addressing production challenges clients faced and driving sustainable growth through innovative technology and continuous support. This experience proves Huvics as a true partner for business growth beyond just being an equipment vendor.

Significance of 30% Production Increase

For the company tackling challenges of maximizing production efficiency and improving quality, the introduction of Huvics’ advanced grinder and cleaner systems stands as a milestone vividly showcasing the astounding changes innovation can bring. Following system implementation, much quicker and more powerful positive changes emerged than expected. Among these, the most significant achievement was that monthly production increased by a remarkable 30%. This monumental result, achieved through line reconfiguration and technological advancements, certainly drew the industry’s attention.

Synergy Between Ultra-Precision Grinding and Cleaning

Huvics’ PKG grinder utilized high-precision stages and diamond wheels to carry out micron-precision processing for various packages like FCBGA, WLCSP, QFN/DFN, Solar Cell as per client thickness specifications with no error. This ultra-precision capability played a decisive role in dramatically reducing defect rates. Moreover, the cleaner machine incorporated multistage cleaning technology with microbubbles, water jets, and air knives alongside perfect Oven Dry features to meticulously eliminate fine contaminants from surfaces of precision parts like camera modules and sensors. The synergy of ultra-precision grinding and flawless cleaning processes significantly reduced initial defect rates, acting as a fundamental factor directly linked to increasing production efficiency.

Huvics is an advanced technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support enhancing customer productivity and securing quality competitiveness through top-notch workforce and continuous technological innovation.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com