Semiconductor equipment investment, ‘blind investment’ is now risky. Are you still thinking, ‘Let’s just get the equipment first’? In a rapidly changing market and intense technological competition, past success formulas are no longer valid. How about starting your journey for a successful semiconductor equipment investment by going through a step-by-step data-driven smart investment strategy with Huvics?

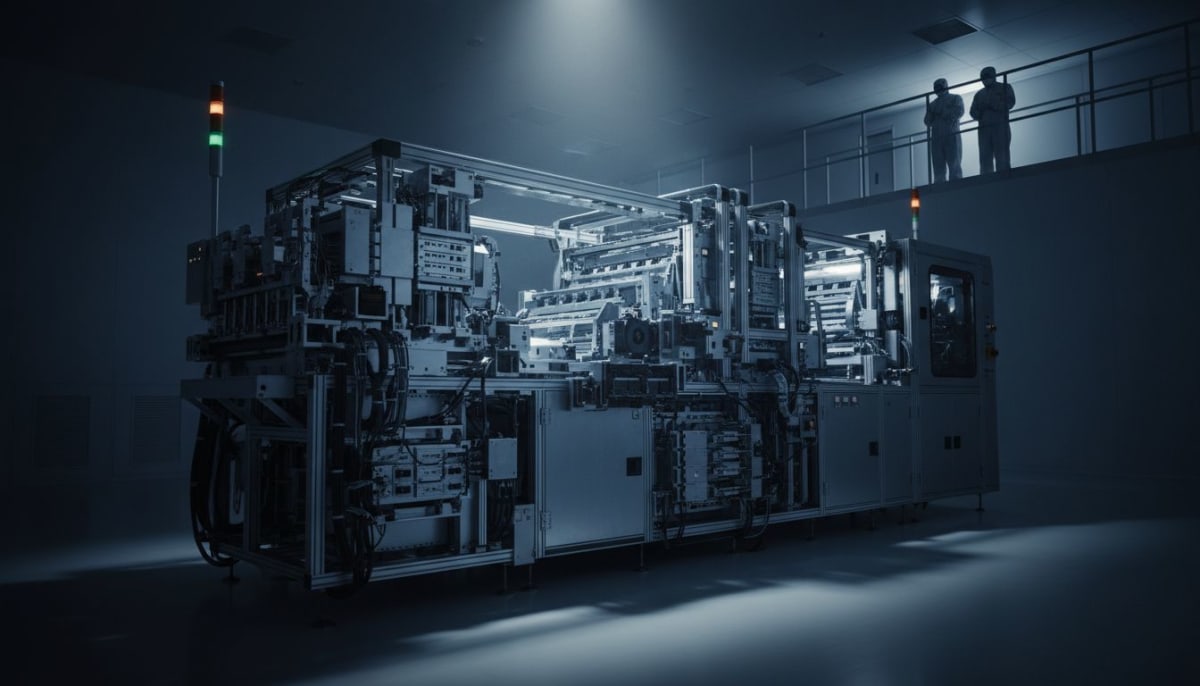

When sketching the big picture of semiconductor equipment investment, many feel uncertain about where to start. Especially when considering the construction of the Grinder System, crucial for ultra-precise processing, the Laminator System to enhance production efficiency, and the Cleaner System responsible for final quality, it can seem even more complex. Huvics is here to solve these concerns and take a solid first step for your successful investment.

Grinder System: Enhancing Precision and Productivity

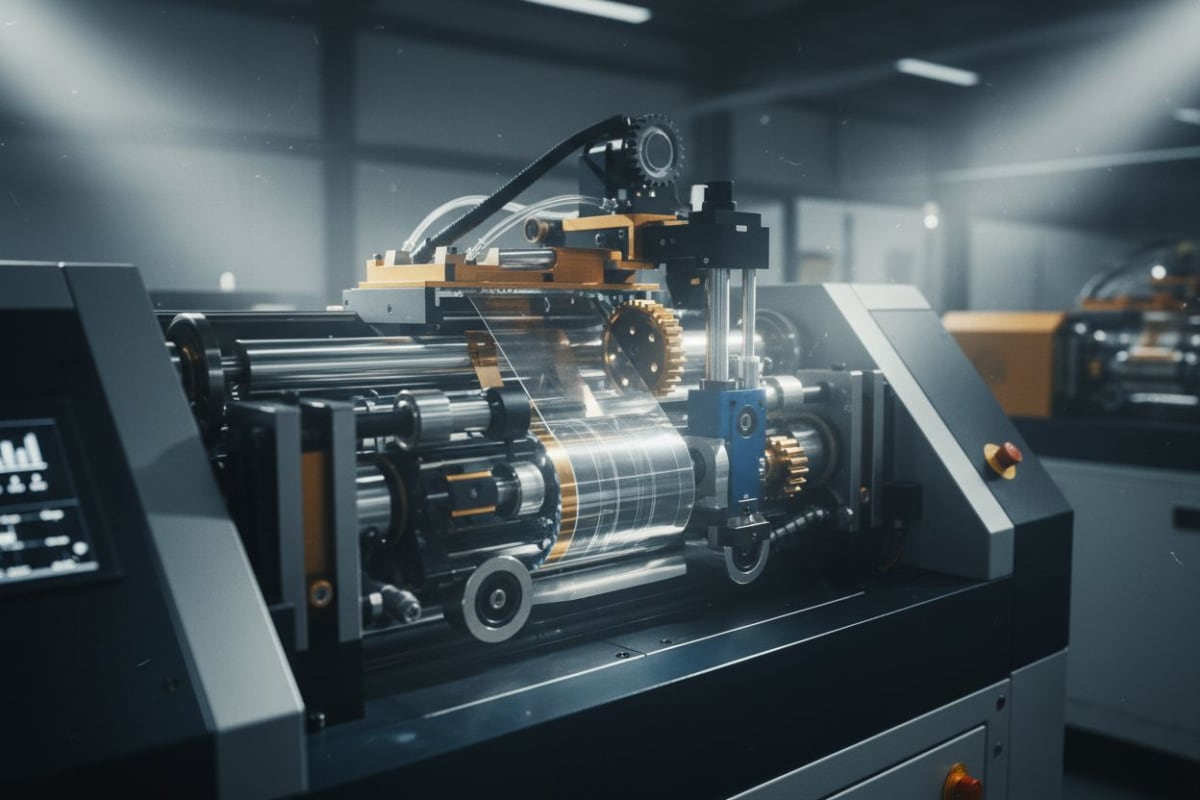

There is often concern about where to focus when investing in semiconductor equipment. Discover the path to maximizing investment efficiency through Huvics’ phased approach. The first and crucial step in successful semiconductor equipment investment is to thoroughly review the implementation of the Grinder System.

Ultra-Precision Processing Technology and Application

The Grinder System plays a very important role in determining the precision of semiconductor package processing. Based on ultra-precision grinding technology, Huvics’ Grinder System processes precisely to the desired thickness with no margin of error, and is applied to various products as follows:

- High-performance packages such as FCBGA, WLCSP, QFN/DFN

- Various products in specific industries such as Solar Cells

This ultra-precision processing capability directly contributes to improving the yield of semiconductor production and lays the groundwork for enhancing the final performance and reliability of products.

System Configuration and Investment Strategy

Also, Huvics offers a wide range of choices to flexibly respond to the characteristics and requirements of various production lines by configuring the Grinder System with Full Auto and Manual Types. Precision Stages and Diamond Wheel technology that control to the micron level are key elements in maximizing production efficiency relative to investment. Therefore, before deciding on the introduction of the Grinder System, it is necessary to meticulously consider not only the initial investment cost but also the expected increase in production volume, quality improvement effects, and long-term operational efficiency.

It is important to critically review whether it is an opportunity to innovate productivity and quality from a long-term perspective and secure sustainable competitiveness beyond simply purchasing equipment. Huvics provides tailored solutions optimized for the client’s unique production environment, and supports successful investment as a robust partner growing together with the client beyond just being an equipment supplier.

Laminator System: Maximizing Production Efficiency through Integrated Processes

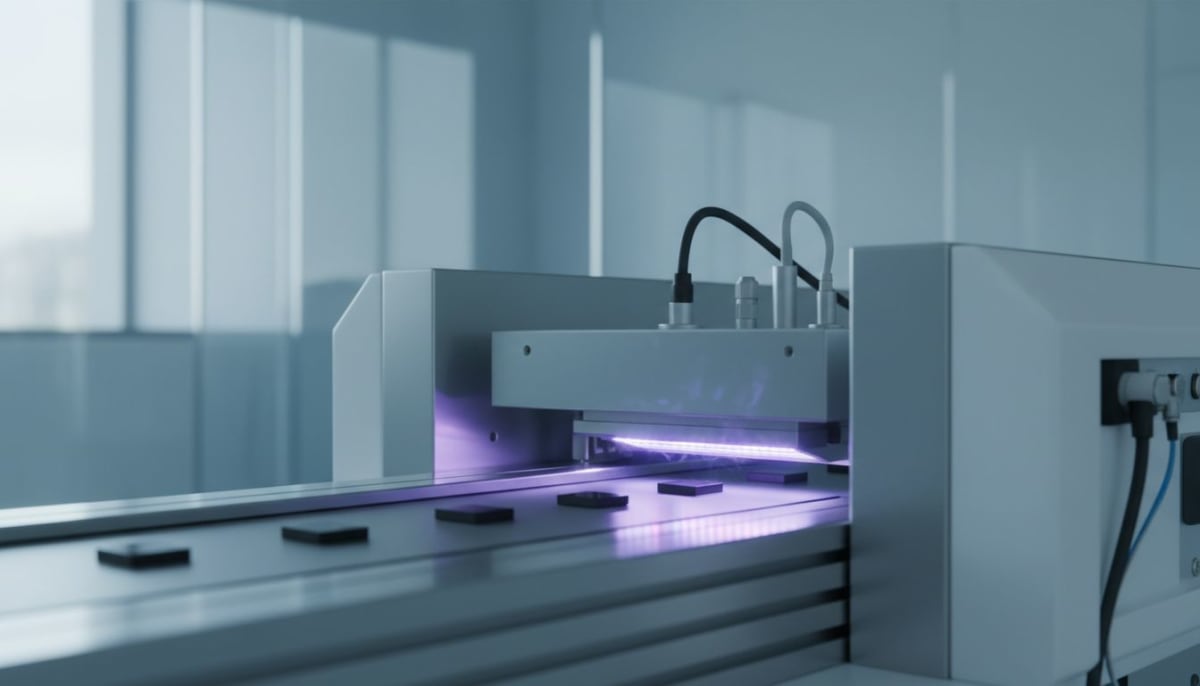

If you’re planning a semiconductor equipment investment, why not proceed with Huvics to the next step of building an efficient Laminator System? In this phase, we will specifically explore how to integrate key processes such as Lamination, Tape Mounting, and UV Curing to maximize production efficiency and ensure the stability of the final product. Lamination is a very important step in the semiconductor production process, and its efficiency has a significant impact on overall productivity.

Enhancing Productivity through Integrated Processes

Huvics’ Laminator System provides the entire Lamination process, from Expander to UV Curing, in a One-Stop system. This integrated system innovatively reduces unnecessary movement and waiting times between processes, simplifying the entire production process and significantly shortening Tact Time, leading to greatly enhanced productivity. This means more products can be produced in a shorter timeframe.

Flexible System and Quality Stability

Additionally, the flexible provision of Semi Auto and Manual options allows for optimal responses tailored to the characteristics and production needs of various products. Not just increasing process speed but also using Lamp/LED UV Curing systems to strengthen adhesive strength and process stability can significantly enhance product reliability. This directly contributes to reducing defect rates and improving the quality stability of the final product.

Establishing the Optimal Investment Strategy

Huvics focuses on providing these detailed technological advantages and integrated solutions to maximize investment value for its clients. Before establishing a Laminator System implementation strategy, it is essential to thoroughly measure and analyze the effects such as Tact Time reduction compared to existing processes, productivity improvement levels, and expected defect rate reduction effects. Huvics actively supports this quantitative measurement process and spares no professional consulting to help clients build the optimal system and achieve smart and efficient semiconductor equipment investment.

Cleaner System: Key to Ensuring Final Quality Stability

The journey of semiconductor equipment investment with Huvics has now reached the crucial stage that determines the final quality. Today, we will delve deeply into the final and essential phase of setting up and optimizing the Cleaner System. No matter how precise the processing and perfect the lamination, fine contamination particles that occur in the semiconductor production process can be a critical factor compromising the functionality and reliability of the final product.

Effects of Multi-Stage Cleaning Technology

With a deep understanding of such contamination issues, Huvics offers a high-performance Cleaner Machine equipped with multi-stage cleaning technology. By optimally combining advanced cleaning technologies such as Micro Bubble, Water Jet, and Air Knife, it thoroughly removes even invisible fine contaminants on product surfaces. This is a crucial stage that firmly ensures the quality stability of the final product.

Optimized Cleaning Solution

Huvics’ Cleaner System is optimized for cleaning a variety of semiconductor and electronic component products such as camera modules, sensors, VCM motors, and trays, demonstrating excellent performance. It is especially equipped with an Oven Dry function to ensure no remnants of moisture or contamination are left after cleaning, taking full responsibility for a perfect drying process. Additionally, the choice of Full Auto or Manual options supports the construction of the optimal system taking into account the degree of automation of the client’s production line and ease of maintenance.

Continuous Management and Partnership

Here, Huvics’ role doesn’t end with just providing equipment. Even after constructing the Cleaner System, we continuously monitor particle removal efficiency improvements and defect rate reduction effects, seeking necessary optimization plans together. This consistent effort maximizes clients’ investment effects and establishes a solid foundation for successful and predictable semiconductor production. Huvics promises to be the strongest partner in securing clients’ final quality stability.

Synergy Effect through System Integration

We have previously examined the importance of each of the Grinder System, Laminator System, and Cleaner System. Now, I would like to discuss how these individual systems are integrated to create synergies, and why equipment investment should be considered from an integrated perspective. Especially, the Grinder System, crucial for ultra-precise processing, and the Cleaner System, responsible for final quality, are closely interconnected.

Linkage between Grinder and Cleaner Systems

Even if grinding is completed meticulously, if any fine contaminants inevitably generated in the process remain, it is difficult to guarantee the quality and reliability of the final product. Huvics emphasizes the point where the precision processing capability of the Grinder System and the perfect decontamination capability of the Cleaner System should synergize. Through an integrated solution that removes residual contamination with a multi-stage cleaning technology applied Cleaner System using Micro Bubble, Water Jet, Air Knife, and micron-level precision machining implemented with Precision Stage and Diamond Wheel, the completeness of the process can be maximized.

Core Value of Integrated Solution

This integrated approach ensures stable quality that does not waver even in high-speed processes, significantly improving production yield and drastically reducing defect rates due to fine particles, securing the quality stability of the final products. Ultimately, this leads to improved productivity and reduced operational costs, becoming a key driver that enhances the market competitiveness of the customer’s company. Huvics plays a decisive role in achieving successful outcomes in semiconductor equipment investment by deeply understanding and reflecting the needs of clients beyond simple equipment supply, through customized equipment design and innovative technology.

If you have carefully reviewed and followed each step of the semiconductor equipment investment journey, you have surely realized that the final quality determines the fruition of all investments. The fact that even the slightest contamination can undermine the product’s reliability after an elaborate process vividly shows that the Cleaner System is not just the finishing step but the core to investment success. Huvics deeply understands the importance of this final quality and helps ensure your precious investment leads to the best results through multi-stage cleaning technology. Remember, building a faultless cleaner system is the surest way to promise productivity improvements and high competitiveness.

Huvics is a high-tech company that develops and manufactures automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support improving customer productivity and securing quality competitiveness with top-notch personnel and continuous technological innovation.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com