According to data from the Korea Semiconductor Industry Association in 2023, the semiconductor cleaning market shows a steady growth rate of an average of 7% per year. This indicates that as semiconductor processing becomes more refined, the importance of cleaning technology is increasing. To advanced electronics manufacturers, this market trend suggests that establishing a ‘more meticulous and efficient cleaning system’ is essential for securing corporate competitiveness. Huvics aims to meet this market demand by partnering with you on a journey to maximize your production efficiency and dramatically reduce defect rates with a 3-step cleaning technology solution.

In the semiconductor and advanced electronics component industry, the process known as ‘cleaning’ goes beyond simple dust removal. In this intricate and complex process, cleaning is a crucial step directly linked to product performance and sometimes becomes a key factor that determines the final quality. If even the slightest contaminants are not properly removed during the cleaning stage, it can critically impact the entire subsequent process, causing defect rates to soar and production yield to decline noticeably. This is a serious problem that leads to weakened corporate competitiveness.

Huvics presents a systematic and effective solution for companies facing these challenges. Our 3-step solution, which eliminates the uncertainties of complex cleaning processes to ensure the highest yield and quality, supports the establishment of a stable production environment. Just like constructing a solid building requires careful planning, construction, and finishing stages, a systematic approach is essential for a cleaning system. Let’s explore the 3-step journey for building a cleaning system proposed by Huvics, which minimizes defect rates and maximizes yields.

Step 1: Identify and Optimize Core Cleaning Technology

The first and most fundamental stage in establishing a cleaning system is to precisely understand the ‘core technology.’ Similar to prescribing the most appropriate medicine for a patient’s symptoms, it is crucial to analyze the characteristics of the product to be cleaned and the type of contaminants in detail and choose an optimized cleaning technology. For instance, microscopic contaminants that are much thinner than a human hair are difficult to remove using general cleaning methods.

Key Cleaning Technologies of Huvics Cleaner

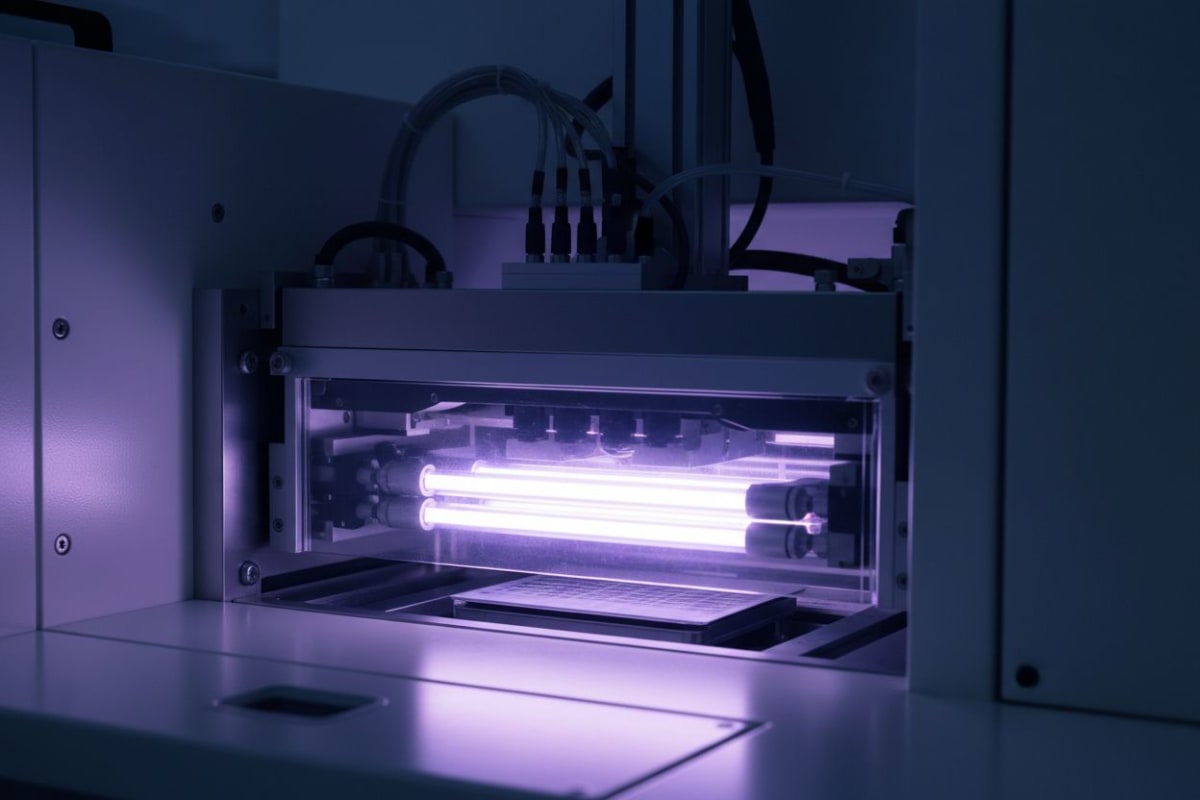

The main cleaning technologies applied in Huvics’ cleaner system are as follows:

- Micro Bubble Technology: Effectively separates and removes contaminants from product gaps with ultra-fine bubbles

- Water Jet Technology: Efficiently cleans adhesive contaminants with powerful water pressure

- Air Knife Technology: Prevents water spots and residues through precision drying

Customized Technology Application and Process Completeness

The synergy of these multi-stage cleaning technologies with different characteristics plays a decisive role in maximizing cleaning power and raising product cleanliness to the highest level when moving to subsequent processes, significantly lowering the possibility of defects. Huvics contributes to increasing the completeness of the entire process beyond simple cleaning by applying customized technologies considering the characteristics of various products such as camera modules, sensors, and VCM motors.

Step 2: Build the Optimal System for the Production Environment

Once the cleaning technology is clearly understood, the next step is to choose the ‘optimal system’ to contain this technology. Just like a superb engine cannot perform if not matched with the right body, it is important to choose a system suitable for the scale and characteristics of the production line and the required level of automation.

System Selection by Production Environment

The system selection by production environment is as follows:

- Full Auto System: Suitable for mass production factories, advantageous for production efficiency and labor cost reduction

- Manual Type: Suitable for small quantity, multi-variety production or specific process precision cleaning, contributing to work flexibility and operational cost efficiency

Customized System Design and Maximization of Productivity

Huvics not only provides technology but also offers a wide range of choices for full auto and manual types depending on the customer’s production environment and goals, creating an optimal cleaning environment by reflecting detailed requirements, such as whether to equip with an oven dry function. This becomes a strategic investment that maximizes customers’ productivity and stable quality control, beyond merely purchasing cleaning equipment. Huvics understands the specific situations customers face and presents the most efficient cleaning system solutions, leading to production yield and product quality stabilization that exceeds expectations.

Step 3: Stabilization of Quality and Yield Through Efficient Operation

Once the optimal cleaning system has been successfully implemented, the third step is to establish and consistently execute an ‘efficient operation plan’ to maximize its potential. Just as a high-end sports car requires proper driving skills and constant maintenance to perform at its best, a cleaning system also needs delicate operation and management. Simply installing the equipment does not allow you to enjoy all the benefits of high-performance cleaning.

Huvics’ Efficient Operation Support

Huvics ensures that the cleaning system maintains the highest particle removal efficiency at all times to practically reduce defect rates and consistently stabilize the final quality of all products produced. Huvics provides the following support for efficient system operation:

- Providing equipment operation manuals and supporting regular inspections and maintenance services

- Extending system lifespan and minimizing unexpected problems

- Listening to production site changes and requirements to provide feedback

- Continuously providing solutions for system upgrades and process improvements

A Key Partner Leading Quality Innovation

In this way, Huvics’ cleaner systems are not just equipment but also serve as key partners invigorating customers’ production lines and leading quality innovation. Huvics promises to be a reliable partner that allows customers to secure stable competitiveness and ultimately be recognized for the highest quality in the market within the ever-evolving manufacturing environment.

In the advanced industry, the reality that even a microscopic contaminant can determine a product’s fate and is directly linked to production yield is always one of the biggest concerns for manufacturing companies. However, with the three-step cleaning solution proposed by Huvics, which addresses everything from technology identification to optimal system establishment and efficient operation, these concerns can be resolved clearly. Beyond simply supplying equipment, Huvics’ cleaner systems, which understand and support the entire production process of customers, will be the most reliable choice for unwavering quality and stable yields. This systematic journey will ultimately become the key driver for customers to be recognized for the highest quality in the market.

Huvics is a high-tech company that develops and manufactures automation equipment and production systems across the semiconductor, LED, mobile, and cosmetic industries.

We support customers’ productivity improvement and quality competitiveness with the best personnel and continuous technological innovation.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com