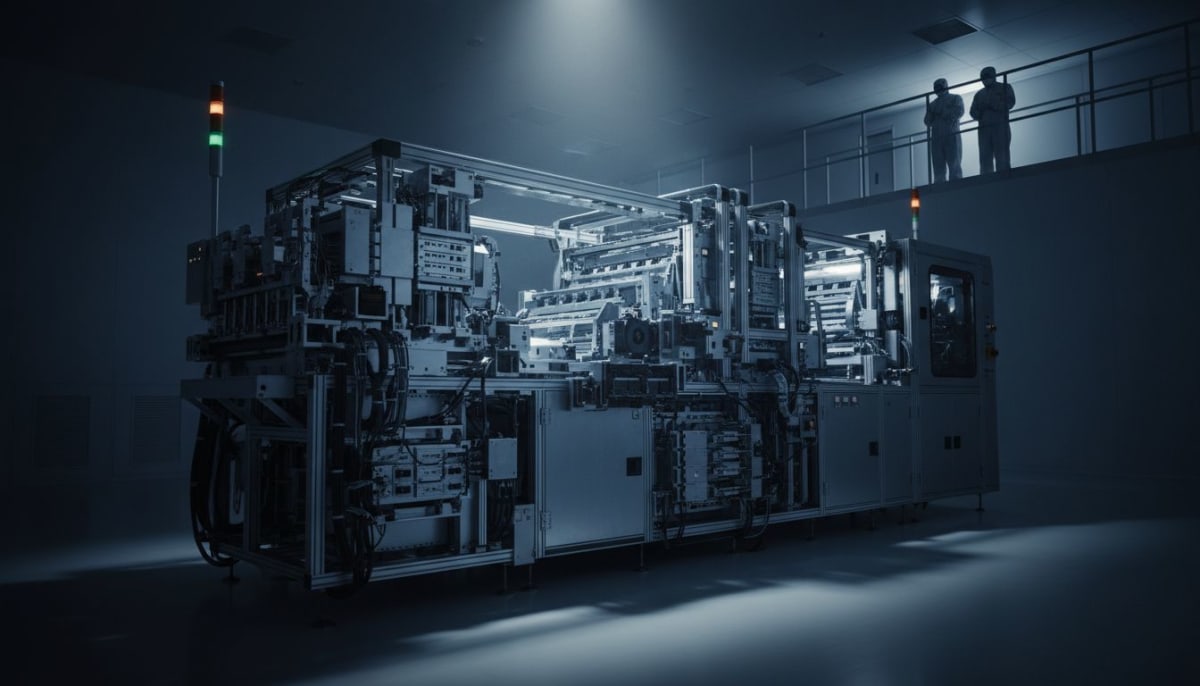

Did you know that by just replacing a single laminator system in a semiconductor production line, you can increase production by up to 30%? Huvics’ laminator system not only replaces equipment but revolutionizes the production process itself to create amazing returns on investment (ROI). This article will delve into a real-world case of Company A, explaining how Huvics’ laminator system optimizes processes and maximizes corporate profitability.

Huvics Laminator System, Innovation in Production Process

In the semiconductor and advanced electronics components industry, production efficiency is a key competitive edge directly linked to corporate survival. In environments demanding ultra-precision processing and extreme reliability, even minor inefficiencies can lead to significant losses. Amidst these stringent market demands, Huvics sets a new industry standard by offering equipment designed to meet individual customer needs and innovative technological solutions aimed at maximizing productivity.

Integrated Process Solutions and Efficiency

Company A’s success story clearly shows how Huvics’ laminator system dramatically increases production through process optimization, thereby maximizing corporate profitability. Huvics’ laminator system integrates key processes such as lamination, tape mounting, and UV curing into a single seamless flow, eliminating unnecessary steps and maximizing overall efficiency. The one-stop process flowing from Expander to the final UV curing stage saves time and human resources, significantly increasing the processing throughput. Huvics promises to continuously develop tailored solutions to meet specific customer needs, thus becoming the most reliable technical partner for customers’ ongoing success.

Huvics Tailored Solution for Company A’s Challenges

Production Challenges Faced by Company A

The advanced semiconductor industry faces intense technological competition and market changes every moment. Company A was no exception. They were in a situation where they had to simultaneously solve two significant challenges: improving productivity and producing high-quality products. Particularly in the laminating process, where precision processing is essential, issues like aging equipment, low productivity, unexpectedly high defect rates, and a poor working environment that adds to worker fatigue were serious problems hindering corporate competitiveness. With the advent of the era of small quantity batch production, a fundamental solution was urgently needed to expand the production line scale and produce diverse products stably.

Background of Choosing Huvics Solution

After deep consideration and thorough market analysis, Company A chose Huvics’ laminator system. Company A focused on Huvics’ capability to provide integrated solutions that maximize precision processing technology, optimal process efficiency, and unwavering quality reliability demanded by the semiconductor and advanced electronics components industry. Acknowledging Huvics’ unique technical ability to analyze customer-specific production environments and requirements thoroughly to design optimal equipment, Company A placed significant trust. This was more than just acquiring equipment; it was a strategic decision to improve the production system’s structure.

Implementation of Customized Integrated Process

Huvics’ laminator system is a highly precise integrated solution designed to solve the problems Company A faced. By integrating complex key processes such as lamination, tape mounting, and UV curing, the system eliminates inefficient steps to significantly boost production efficiency. Company A could establish a comprehensive one-stop lamination process covering all stages from the Expander to final UV curing. It played a decisive role in drastically shortening the production Tact Time and hence, markedly improving Company A’s productivity. Moreover, the introduction of the latest lamp/LED UV curing system optimizes adhesion strength and enhances process stability, significantly reducing the previously problematic high defect rates. This technological innovation provided Company A with a strong platform to secure a sustainable competitive edge beyond mere equipment upgrades.

From System Introduction to Onsite Optimization: A Successful Process

System Installation and Initial Stabilization

After the introduction of the Huvics laminator system to Company A’s production line, a wave of transformative change ensued. Let’s closely examine the entire process over time to see how this remarkable change unfolded. The initial step involved precise installation and initial testing of the new laminator system. Given the highly complex nature of the equipment, unforeseen issues could emerge despite thorough preparation. However, Huvics’ expert engineers were well-prepared, quickly diagnosing root problems and presenting optimal solutions to ensure the system’s flawless operation.

Customized Onsite Worker Training

Following system installation and stabilization, a crucial step was the training of onsite workers. Regardless of the system’s quality, it cannot function at its best without the proficiency of its operators. Huvics provided customized training programs to equip Company A’s workers with a comprehensive understanding of the new system and skilled handling. From the laminator system’s complex operational principles to everyday maintenance and safety protocols, workers systematically learned everything to eliminate fears of new technology and gain confidence. This training significantly influenced early system stabilization.

Production Line Optimization and Efficiency Improvement

Subsequent to the above stages, the full-scale production line optimization process began. The automation features of Huvics’ laminator system dramatically enhanced production speed compared to previous levels. Additionally, micron-level precision control technology played a crucial role in significantly reducing defect rates and enhancing product quality consistency. With an intuitive and user-friendly interface, operators found it easy and convenient to manage and control complex processes, directly enhancing work efficiency.

Continuous Support and Successful Outcomes

Of course, this optimization process was not entirely smooth. Initially, unexpected system errors and unfamiliarity with the new equipment resulted in temporary challenges. However, Huvics consistently communicated with Company A, offering ongoing technical support and promptly finding solutions to problems as they arose. As a result, Company A’s production line, powered by Huvics’ laminator system, achieved remarkable success in enhancing productivity, reducing defect rates through cost savings, and ultimately improving quality. Huvics will continue to prioritize customer success, continually striving to provide the best technology and services.

Innovative Achievements and ROI That Huvics System Brought to Company A

The semiconductor and advanced electronics components industries are where production efficiency and quality reliability are key factors determining a company’s survival. Within this rigorous environment, Company A attracted industry attention by achieving notable achievements through the introduction of Huvics’ laminator system. What changes did the Huvics laminator system bring to Company A? Now, it’s time to confirm the high ROI this system delivered through its vivid story.

Key Performance Indicators and ROI

The results, once Huvics’ laminator system was fully established on Company A’s production line, were astonishing. Compared to before its introduction, Company A achieved an impressive 30% increase in production, a 15% reduction in defect rates, and a 20% reduction in overall working time. These figures are not merely statistical results. They directly fueled Company A’s significant cost reductions, enhanced market competitiveness, and ultimately innovative improvement in corporate profitability. Particularly, the Lamination process that performed all stages from the Expander to UV Curing as a one-stop process dramatically shortened production Tact Time and maximized productivity, clearly proving Company A’s investment utility.

A Candid Testimonial from Company A Representative

A representative from Company A shared their thoughts on this success story. “The introduction of the Huvics laminator system was not merely a replacement of obsolete equipment but a crucial turning point that revolutionized our entire production process at Company A. Particularly, the reduction in working hours positively affected employee fatigue reduction and satisfaction, rejuvenating the corporation overall.” Of course, any new system requires an adaptation period. Company A also faced some difficulty due to unfamiliarity with the new system, but swift and active technical support and customized training optimized for the site from Huvics facilitated rapid system stabilization.

Implications of the Success Story

This successful case of Company A reminds us of how important precise problem diagnosis and the application of the most suitable optimal solutions are. Company A maximized the efficiency of its production processes through the introduction of Huvics’ laminator system and succeeded in achieving quality stability from a long-term perspective, essentially catching “two rabbits.” This successful process innovation story isn’t unique to Company A. It is a clear implication for other manufacturing companies. It provides a powerful message that with a reliable technology partner like Huvics, any company can transcend production process limits, achieve innovation, and realize the highest ROI from investment.

The fact that production efficiency is the key element determining corporate survival is once again clearly highlighted through Company A’s success story. Huvics’ laminator system didn’t just replace equipment but proved that by integrating and optimizing core processes, it achieved production increases, defect rate reductions, and, moreover, a high ROI. This precisely shows how a company can overcome challenges and achieve innovation with accurate problem diagnosis and optimal technical solutions. Now, it’s time for Company A’s case to set a new benchmark for competitiveness in your production process.

Huvics is a high-tech company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support our customers in improving productivity and securing quality competitiveness with top-notch personnel and continuous technological innovation.

Huvics Inquiries

Phone: 031-374-8285

Email: cdpark@hKvics.com