Many semiconductor companies continue to face challenges in flexibly transitioning production capacity and consistently maintaining top quality amidst rapidly changing market environments. These challenges include:

- Quality instability due to stagnant production volumes and minor defects

- Lack of responsiveness to the demands for small-scale production with diverse items and advanced packaging technology

These obstacles not only hinder a company’s growth but also incur significant opportunity costs, prompting the question of whether it’s possible to improve both efficiency and quality in production simultaneously.

In the semiconductor industry, speed and precision are of utmost importance. Overcoming production capacity limitations and maintaining the highest quality amidst rapidly changing market demands and competition in nanometer-scale technology have become crucial for all companies. Just a few months ago, challenges of stagnant production volumes and quality instability due to microscopic defects posed significant pressures on companies.

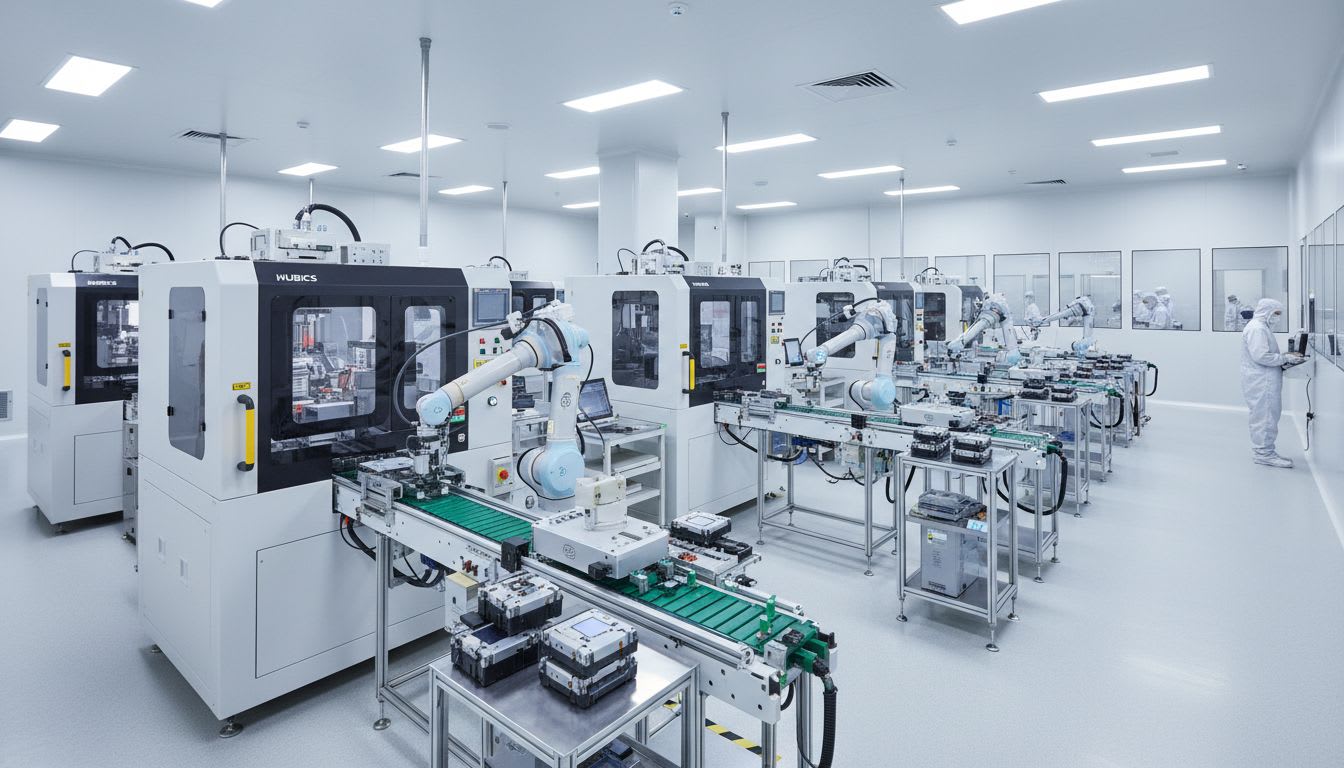

However, Huvics drew industry attention by drastically transforming its production capacity within just one remarkable month, despite these daunting circumstances. How was such an innovative transformation possible? It was the synergy of three key technologies—Grinder System, Cleaner Machine, and PKG Grinder—that set new standards in semiconductor production. Through this article, you will gain an in-depth analysis of the secrets to their success and acquire practical insights necessary for future production strategies.

Grinder System for a Flexible Production Environment

Implementation of a Flexible Production Environment

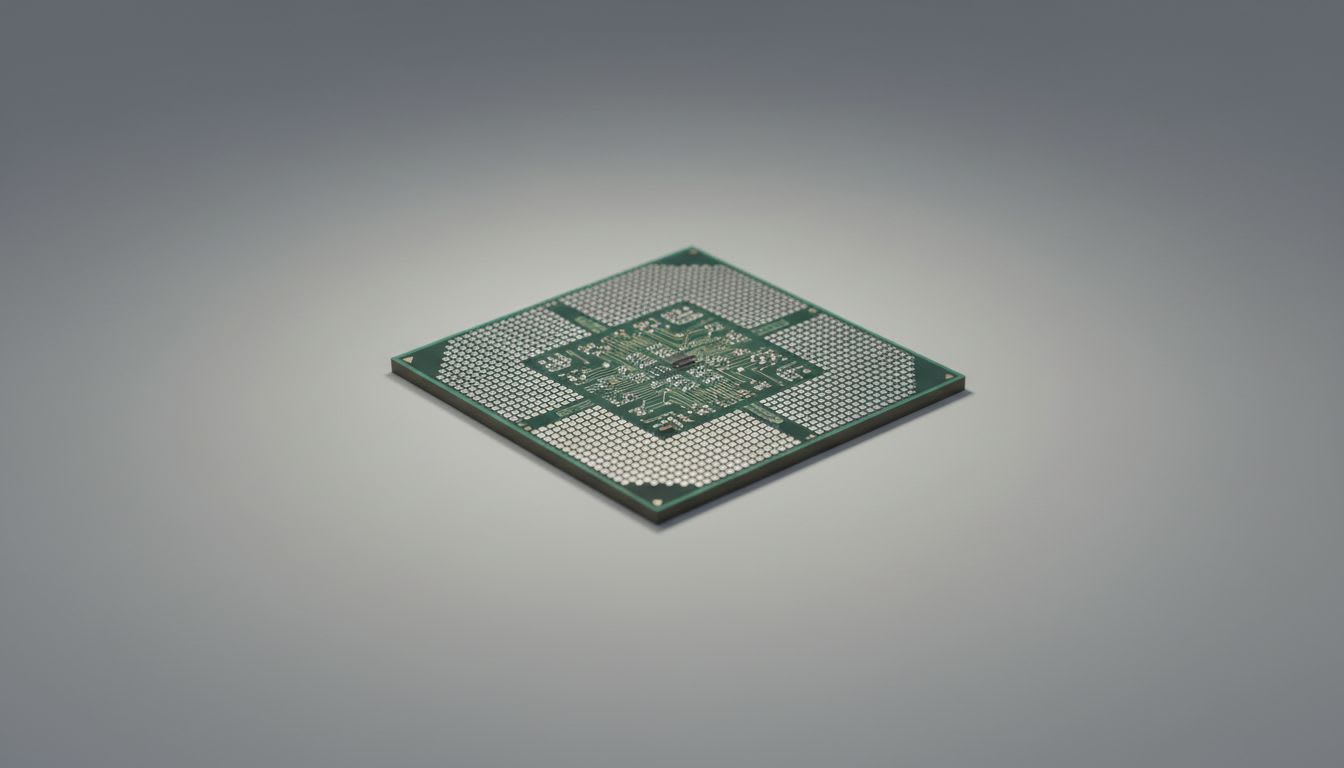

At the core of Huvics’ innovation lies the Grinder System, enabling a flexible production environment. The era of single product mass production in semiconductor manufacturing is over. Flexibility in scaling production in accordance with market demands, ranging from small-scale production of diverse types to mass production, is essential. Huvics’ Grinder System meets these demands perfectly, supporting both Full Auto and Manual types. This provides the ability to optimize production lines and swiftly respond to volatile market conditions at any given time.

Advantages of High-Precision Grinding Technology

Additionally, based on high-precision grinding technology, this system ensures consistent and stable quality in semiconductor wafer processing. In semiconductor processes, where even slight variations in wafer thickness are unacceptable, such high-precision processing capabilities are crucial for maximizing production efficiency and significantly reducing defect rates. Consequently, through this Grinder System, Huvics successfully increased production capacity within a short time span and significantly enhanced the overall stability of its production processes.

Cleaner Machine for Perfect Quality

In semiconductor production, invisible microscopic contamination can lead to critical defects, which in turn result in reduced product reliability and substantial financial losses. Huvics provides a powerful solution for perfect quality by introducing the Cleaner Machine to eliminate such fundamental causes of quality degradation. Beyond simple cleaning, this machine integrates multiple stages of precision cleaning technologies, such as micro-bubbles, water jets, and air knives, to meticulously remove fine contaminants clinging to product surfaces. It’s optimized for cleaning a variety of sensitive semiconductor components like camera modules, sensors, VCM motors, and trays, ensuring the best cleaning effects for any type of product. Moreover, the Oven Dry function handles the complete drying process post-cleaning, fundamentally preventing the possibility of secondary contamination or defects due to residual moisture during the drying process. This outstanding performance of Huvics’ Cleaner Machine plays a decisive role in maximizing particle removal efficiency and securing the quality stability of final products, dramatically reducing defect rates for clients.

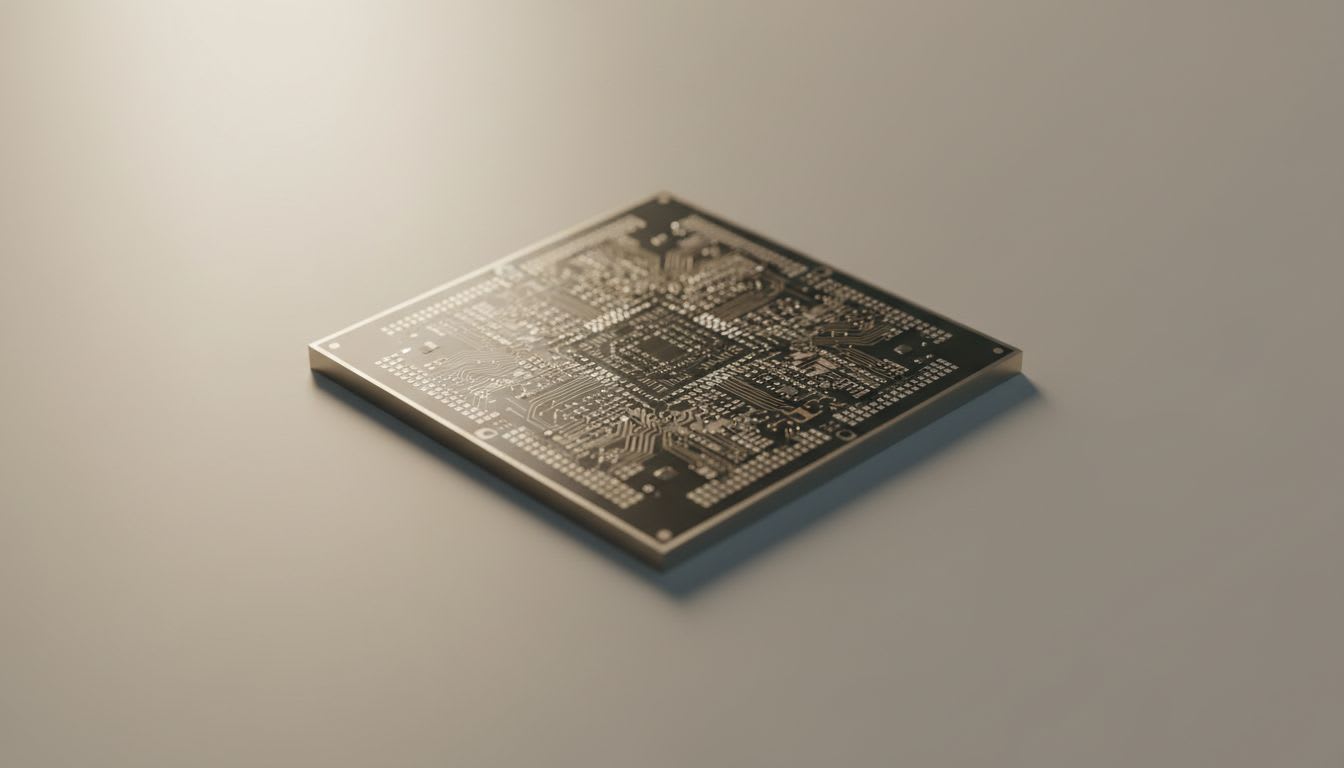

PKG Grinder for Advanced Packaging Technology

Response to Advanced Packaging Market

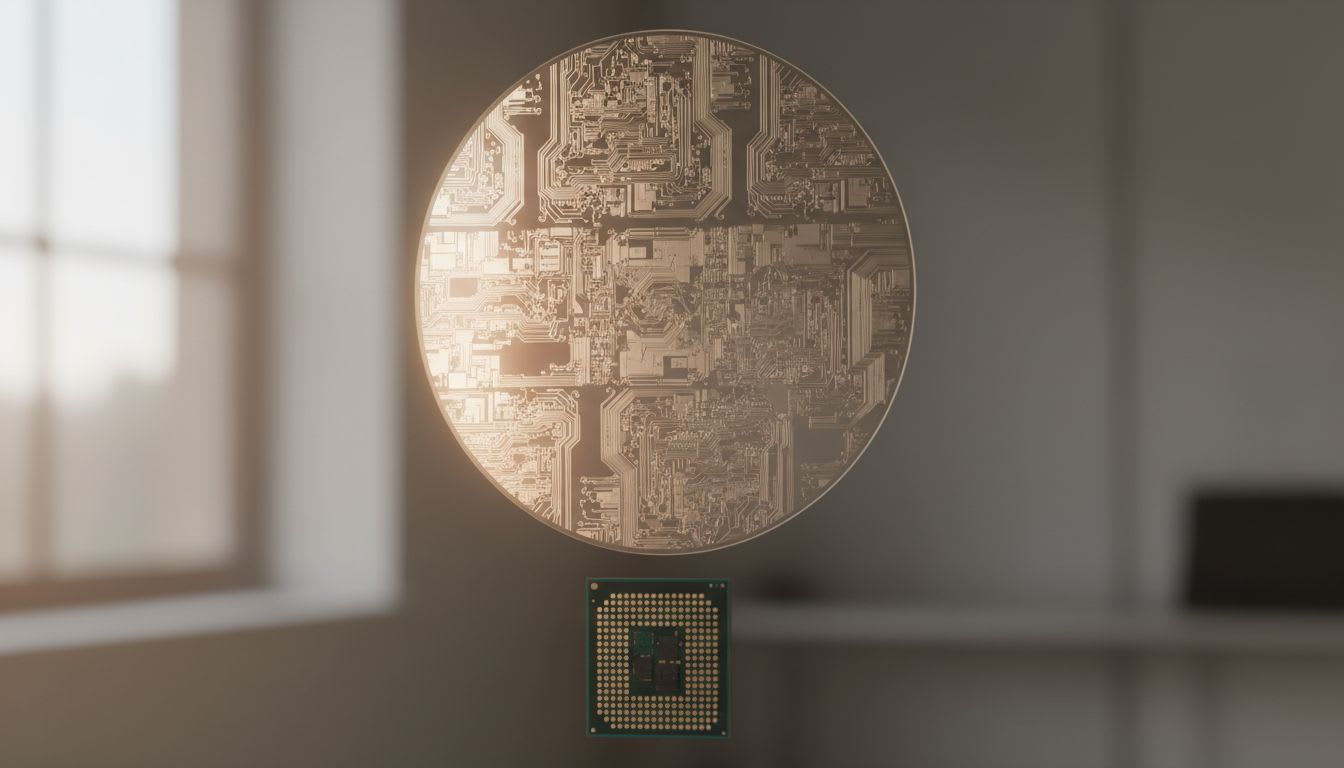

The modern semiconductor industry demands not only circuit integration but also advanced packaging technology with diverse functions and forms. The importance of technology for precisely processing complex and intricate packages like FCBGA, WLCSP, QFN/DFN, and Solar Cells is increasingly emphasized due to rising demand. Huvics’ PKG Grinder was developed to meet these latest market demands with its high-precision grinding equipment.

High-Precision Processing Ability and Future Potential

This equipment boasts consistent and precise processing abilities that allow no micron (µm) level deviations, achieving the desired thickness for customers. Utilizing advanced high-precision stages and specialized diamond wheels, it perfectly processes even the micro areas of semiconductor packages, fully meeting the ultra-precision specifications essential for next-generation semiconductor processes. This unique technology of the PKG Grinder became the pivotal force empowering Huvics to elevate its production capacity of next-generation semiconductor products within a mere month. Thus, Huvics, through this system, established a foundation for not only increasing production volume but also reliably producing high-quality complex semiconductor packages, presenting new possibilities for future semiconductor manufacturing.

The longstanding issue of production stagnation and quality instability due to minor defects continues to constrain many companies in the semiconductor production field. Yet, the integrated combination of Huvics’ Grinder System, Cleaner Machine, and PKG Grinder does more than just boost production capacity within a month. It sets a new standard for future semiconductor production, enabling flexible adaptation to rapidly changing market demands while maintaining ultra-precise quality. From Huvics’ example, we can now gain valuable insights that integrated solutions alone can drive sustainable growth and innovation.

Huvics is an advanced technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

With top talent and continuous technological innovation, we support our clients in improving productivity and securing quality competitiveness.

Huvics Inc. Contact Information

Phone: 031-374-8285

Email: cdpark@huvics.com