In the past, grinders were often thought of as crude machines that simply smoothed rough surfaces. However, as advanced industries like semiconductors and displays have evolved to demand micrometer-level precision, the environment requiring such precision has become standard. Now, grinders have transformed beyond merely cutting materials; they have evolved into ultra-precision processing and integrated solutions that determine the final quality and performance of products. During this era of such demands, companies like Huvics have heightened interest in the true value and role of advanced grinder systems they introduce.

The Core of Ultra-Precision Industries, Evolution of Modern Grinders

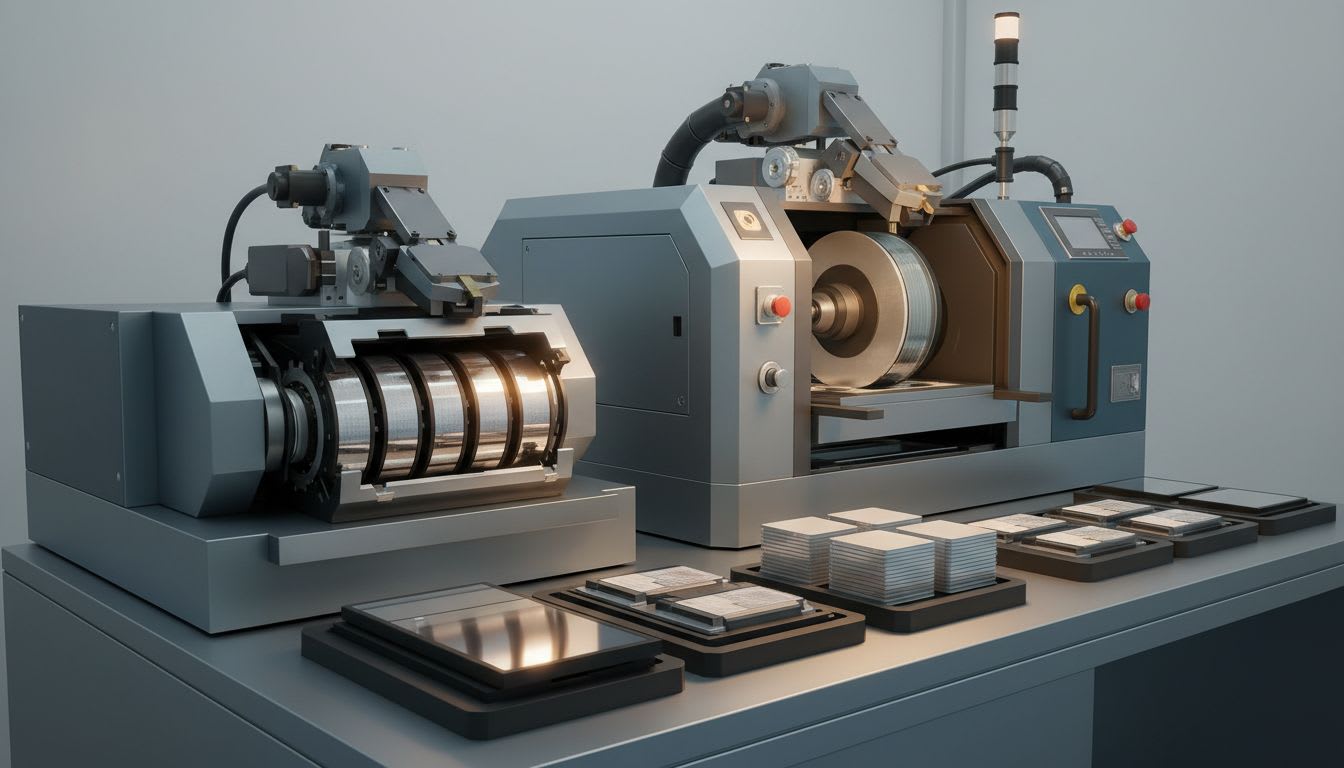

Many people often misunderstand grinders as tools that only coarsely treat metallic surfaces, but the reality of modern industrial grinders used in ultra-precision manufacturing environments is quite different from this common perception. They have evolved into complex and intelligent systems performing extremely precise processing. Advanced production lines in semiconductors, displays, and medical devices, where minor errors are not tolerated, demand micrometer-level accuracy that cannot be identified by the naked eye. Huvics validates the true value of grinders in these advanced environments, going beyond simply cutting materials, and effectively acting as key equipment driving innovation in industrial sites by achieving meticulous surface treatment and thickness control that are directly tied to the final product’s performance. The fusion of advanced technologies and sophisticated functions in Huvics’ grinders make a decisive contribution to reducing defect rates and enhancing quality stability.

Huvics Ultra-Precision Grinding Technology and Integrated Cleaning Solutions

In modern industries, the role of grinders has evolved beyond merely cutting something, especially in the sensitive processing of semiconductor packages, to become integrated solutions responsible for product integrity and cleanliness. At the heart of the grinder systems presented by Huvics are these cutting-edge ultra-precision grinding technologies backed by advanced components.

Ultra-Precision Grinding Technology

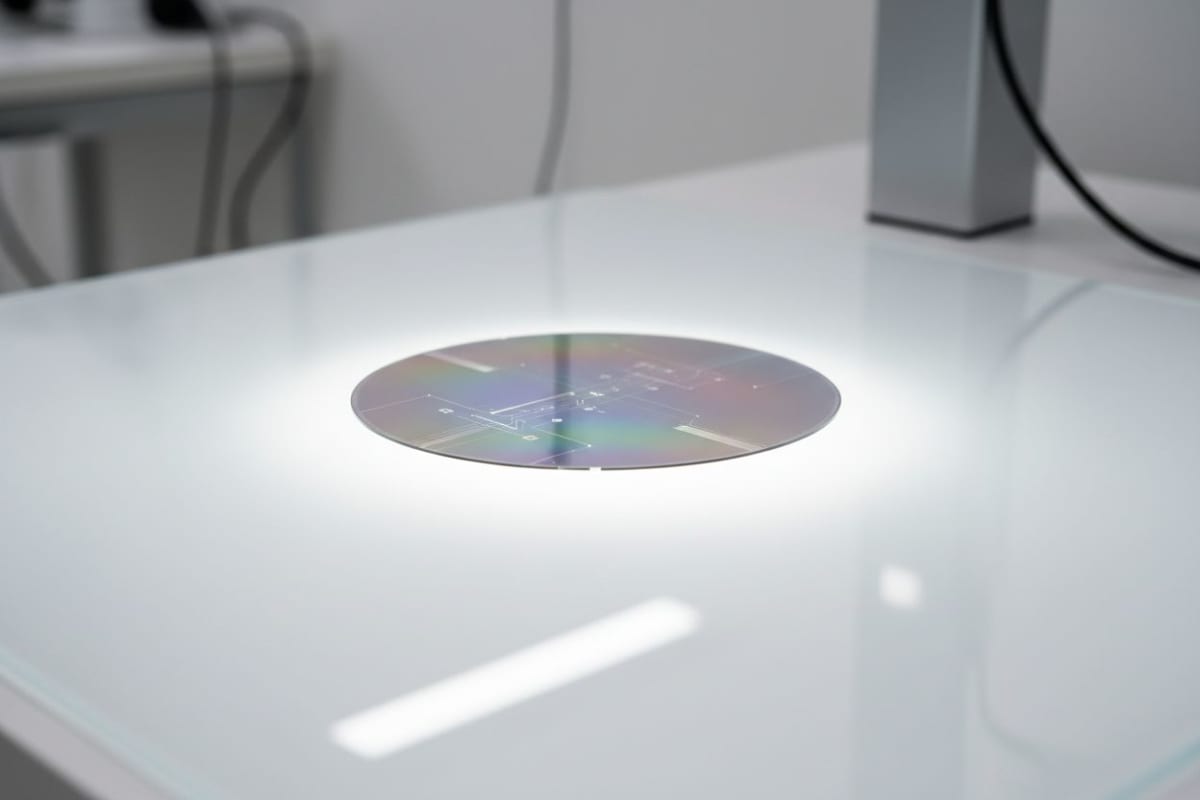

Featuring high-precision stages and diamond wheels, Huvics’ package grinders process a variety of high-value-added packages such as FCBGA, WLCSP, QFN/DFN, and Solar Cell uniformly and precisely without even micrometer-level error. This technology plays a crucial role in minimizing product damage and maximizing final performance in complex semiconductor processes by precisely achieving the desired thickness for customers down to minute, non-visible levels.

Integrated Cleaning and Drying

No matter how precisely materials are cut, failure to completely remove micro-contaminants generated during the grinding process can lead to product defects. In ultra-precision industries, even a contaminant smaller than a strand of hair can paralyze the entire product’s functionality. To resolve such issues, Huvics has integrated cleaner machines as an essential component of the grinder system. Utilizing multi-stage cleaning technologies such as micro bubbles, water jets, and air knives, they thoroughly eliminate contaminants from product surfaces, while the oven dry function completes the thorough drying process. Consequently, the grinder systems by Huvics transcend being just grinding equipment, drastically reducing defect rates and ensuring stability in the final product quality through full automation of precision processing, perfect cleaning, and drying.

Value of Huvics Systems Maximizing Production Efficiency and Quality

The advanced grinder systems from Huvics provide strategic value as a core factor determining the efficiency of production lines and the quality stability of final products, going beyond simple grinding. Huvics’ systems meticulously conduct all processes to guarantee the final quality of a range of high-value-added products.

Applicable Product Range

- Various packages such as FCBGA, WLCSP, QFN/DFN

- Sensitive products like camera modules, sensors, VCM motors, and trays

Productivity Improvement and Flexible Systems

The functional truth of Huvics systems results in a drastic reduction of defect rates while maximizing the quality stability of final products. Furthermore, system configurations that allow flexible selection between full-auto and manual types facilitate automation of customer production processes and provide convenience in maintenance, greatly enhancing operational efficiency. In essence, modern grinders, far exceeding mere processing equipment, provide essential competitiveness in high-value-added product manufacturing, emerging as true partners that aid customers’ success.

Huvics, Providing Precision Solutions for Customer Success

Huvics realizes the true value of grinders by offering precision solutions that exceed mere abrasive functions. The grinder systems at Huvics are designed to allow flexible selection to match the production line environment of their customers.

Customized System Configuration

- Full automation (Full Auto) mode can maximize production efficiency.

- The manual mode allows flexible control over specific processes.

Providing Ultra-Precision Integrated Solutions

These systems, based on ultra-precision grinding technology, enable delicate processing at micrometer levels that the naked eye cannot confirm. From processing to cleaning and drying, Huvics offers ultra-precision technology and integrated solutions with the ultimate goal of maximizing customers’ production efficiency and achieving the highest quality products.

It is time to completely abandon the traditional image of grinders as crude machines. In modern industries, grinders are not simple cutting tools anymore but have evolved into core solutions that determine the final product quality, integrating ultra-precision machining, perfect cleaning, and drying without allowing even micrometer-level error. Through such advanced systems, Huvics dramatically reduces defect rates, maximizes production efficiency, and serves as a reliable partner for the successful business of its customers. Remember that grinders have transcended mere equipment to become entities with strategic value that determine future industrial competitiveness.

Huvics is a leading technology company that develops and manufactures automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

With the best manpower and continuous technological innovation, we support our customers in improving productivity and securing quality competitiveness.

Contact Huvics Co., Ltd

Phone: 031-374-8285

Email: cdpark@huvics.com