Recently, many semiconductor equipment management experts have agreed that ‘the true lifetime of equipment is not determined solely by physical wear and tear but by subtle environmental factors and precise management.’ This means that waiting for a fixed lifespan or repairing after a failure is not enough to maintain optimal production efficiency and quality. Instead, the key is to delicately manage even invisible micro-contamination or process stress. This perspective presents a new standard of viewing semiconductor equipment as not just ‘consumable’ but as a ‘manageable core asset.’ This is where Huvics’s journey of advancement begins.

Huvics Presents a New Paradigm for Equipment Lifetime Management

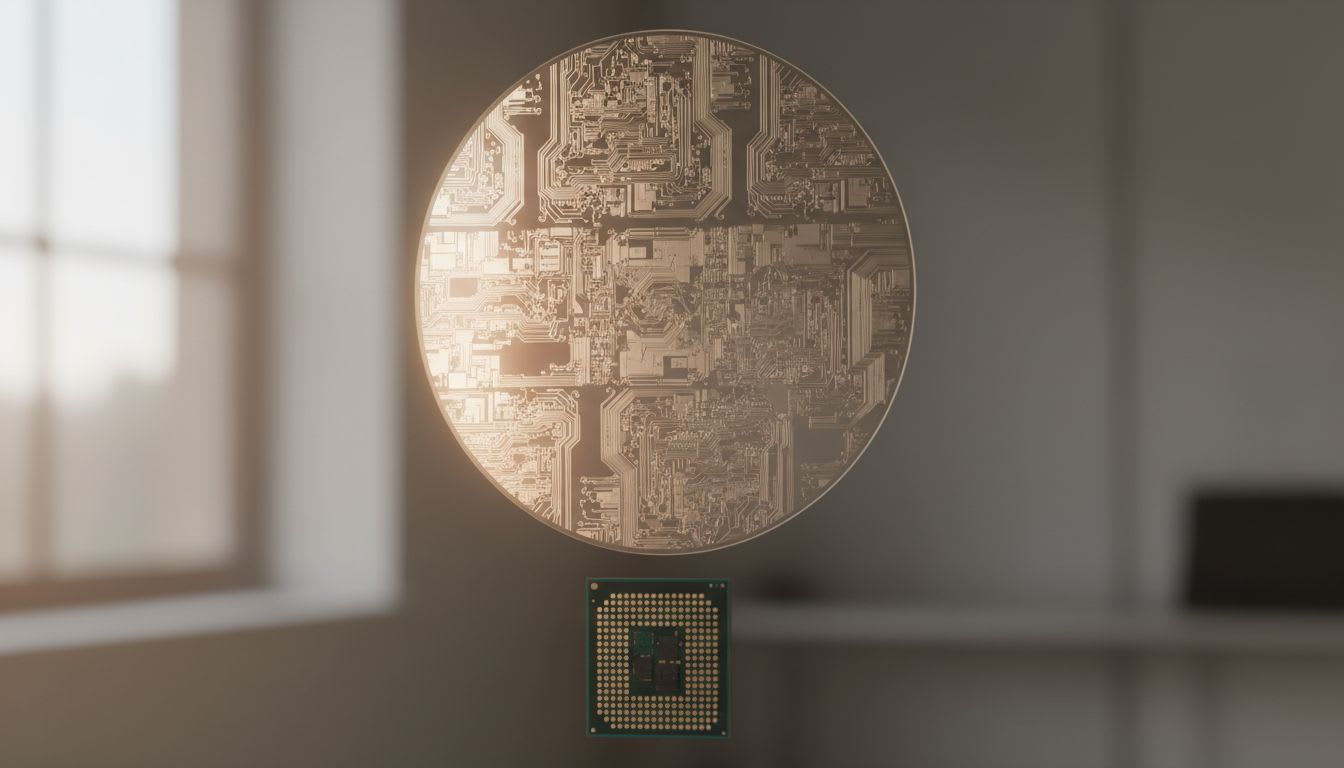

In the competitive arena of advanced technology semiconductor production lines, equipment life transcends mere functionality. It is a crucial variable that can impact not only astronomical investment costs but also production efficiency and final product quality. Initially, it was considered wise to use equipment as long as possible before replacing it after a failure. However, unexpected equipment shutdowns lead to significant losses and prompt fundamental questions.

Is the lifetime of semiconductor equipment predetermined destiny, or can it be an area we can intervene in and optimize through our efforts? This question marked a new journey’s starting point for Huvics. Beyond simply making and selling equipment, we began to define the lifetime of semiconductor equipment, a core aspect of production, as a ‘manageable variable’ and sought innovative solutions. Huvics, from this perspective, is transforming the unpredictable fate of semiconductor equipment lifetime into a key competitive advantage that can be optimized through systematic management and technical prowess.

Perfect Elimination of Micro-contamination with Cleaner Machine

The Root Issue of Micro-contamination

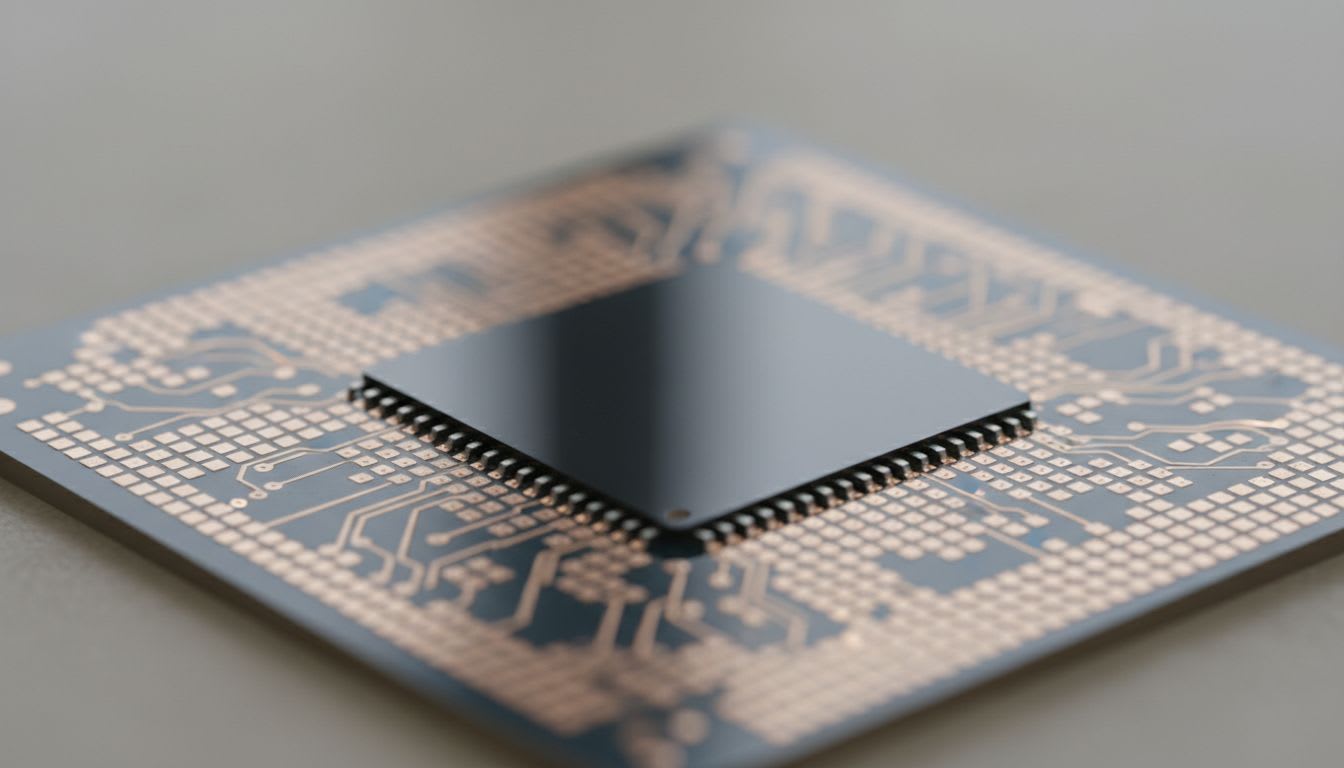

In the prevailing belief that the lifetime of semiconductor equipment is determined solely by physical wear, Huvics started to delve deeper by asking more fundamental questions. Just as an outwardly healthy body can succumb to unseen viruses or stresses, after decades of facing precision processes where even micron-level errors are unacceptable, we realized that invisible micro-particles, relentless microvibrations, and repetitive process stress critically affect equipment performance and lifespan. These invisible threats hinder the potential of equipment, cause unpredictable defects, and ultimately reduce production efficiency. To fully maintain the inherent performance of equipment and use it beyond the expected lifespan, we concluded that a deep insight that meticulously manages operational environments and each internal component is needed.

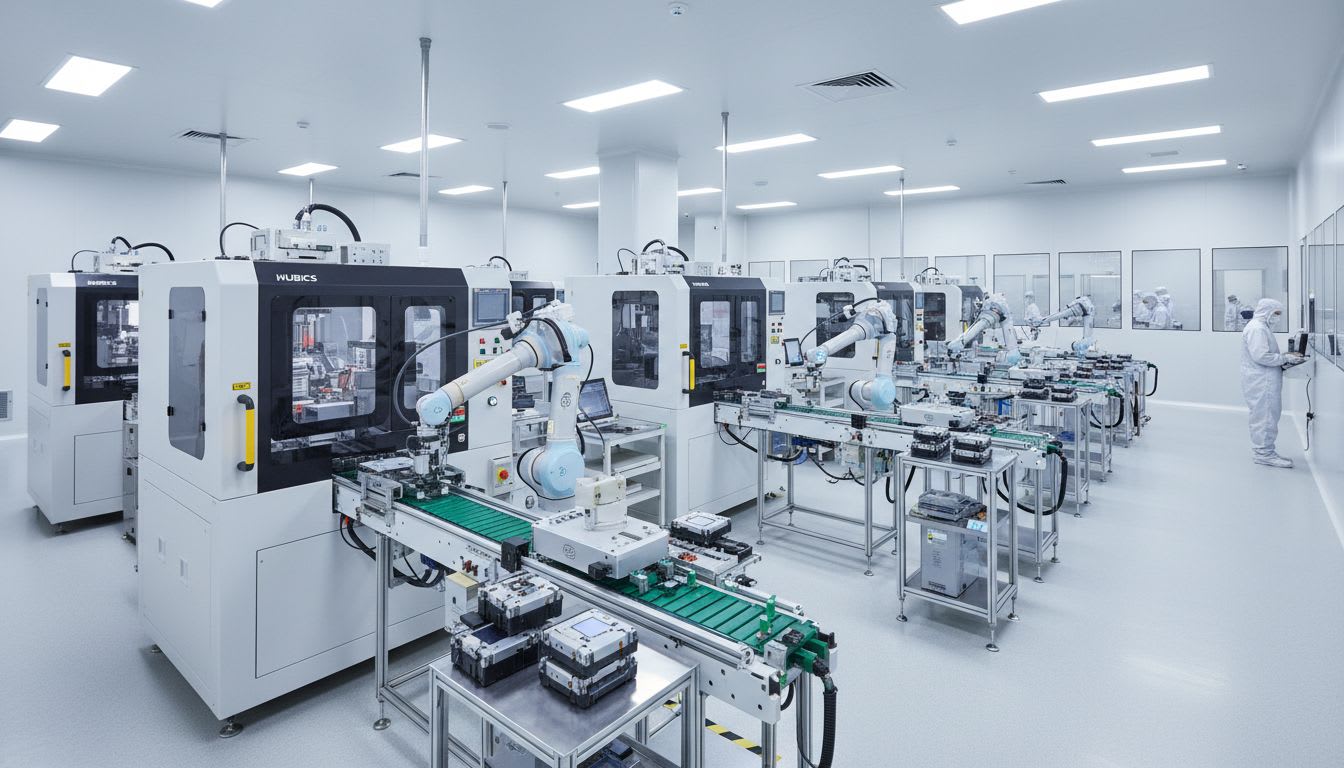

Multi-step Cleaning Technology of the Cleaner Machine

To fundamentally remove the micro-contamination that decisively affects equipment life, Huvics enhanced the Cleaner Machine technology. By integrating multi-step cleaning technologies like Micro Bubble, Water Jet, and Air Knife, we completely remove contamination particles from product surfaces and maximize equipment and product stability with the Oven Dry function for residual moisture control. This effort goes beyond merely reducing defects—it ensures the stability of final product quality by maintaining the inherent precision of equipment over a long period and helps customers’ production lines operate flexibly. Believing that the equipment lifespan is not merely a matter of time passing but a sum of precise efforts in detailed management, Huvics continues to propose innovative solutions, supporting the sustainable growth of the semiconductor industry.

Maintaining Precision with Ultraprecision Grinder System

Alongside microcontamination management, Huvics emphasizes that minimizing potential micro-errors occurring during processes and consistently maintaining the precision demanded by clients is also central to equipment lifetime management. For this purpose, we introduced a flexible Grinder System. Comprising fully automatic and manual types, this ultraprecision grinding equipment, using high-precision Stage and Diamond Wheel, allows for micron-level accurate processing. By processing various packages like FCBGA and WLCSP to the client’s desired thickness uniformly and precisely, we help reduce the load on the equipment and minimize wear, ensuring stable performance beyond the designed life span. This process introduces a new paradigm that focuses not merely on repairing and replacing equipment but on maximizing the potential of the equipment and continuously managing its lifespan. Huvics firmly believes that the lifetime of semiconductor equipment is not just a fixed number but can multiply indefinitely depending on how finely it is managed, and this journey continues unceasingly.

Optimizing Equipment Lifetime and Maximizing Value with Huvics’s Technological Proficiency

Equipment, said to be the heart of the semiconductor industry, must consistently maintain peak performance, but managing their lifespan remains a difficult task. Huvics courageously challenged this inertial view. We believed that, rather than simply accepting equipment life, it can be actively optimized through advanced technology and systematic management. We focused on caring for even the smallest parts of the equipment, maintaining optimal conditions to draw out their maximum potential.

Huvics Core Technology

Huvics’s core technologies include:

- Reducing equipment load and minimizing wear with the ultrafine grinding Grinder System.

- Removing microcontamination with the Cleaner Machine to secure defect reduction and quality stability.

Outcomes of Technology Application

Featuring differentiated technology unique to Huvics at each process stage, these technologies represent critical efforts to maximize equipment potential and extend lifespan. These proactive efforts have brought remarkable changes never experienced before. The disruptions to production lines due to equipment failures significantly decreased, and the noticeable quality stability reduced defect rates visibly.

New Value and Vision

The lifespan of semiconductor equipment is no longer an unpredictable fate, but a significant asset that can be actively extended and optimized through advanced technology and systematic management. With this newfound realization, equipment becomes not just machines but reliable partners that create maximum value through meticulous care. Through this journey, Huvics will continuously research and develop to ensure that the equipment, the core of semiconductor production, will operate for longer than any expectations and with optimum efficiency. This is the ultimate goal and value pursued by Huvics in managing the lifecycle of semiconductor equipment.

If managing the lifetime of equipment in production lines felt like a vague task, it is now time to change that perspective. Huvics’s journey proves that equipment is not merely a consumable that completes its given lifespan, but a core asset that can maximize value through precise technology and systematic management. Through this journey, Huvics will continuously research and develop to ensure that the equipment, the core of semiconductor production, will operate for longer than any expectations and with optimum efficiency. This is the ultimate goal and value pursued by Huvics in managing the lifecycle of semiconductor equipment. Now, your production line can also experience a new future by changing the ‘destiny’ of equipment and achieving beyond-expected results.

Huvics is an advanced technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

Our goal is to support improved productivity and secured quality competitiveness for our clients through the best talents and continuous technological innovation.

Contact Huvics

Phone: 031-374-8285

Email: cdpark@huvics.com