Many people recognize the importance of UV Curing, or ultraviolet curing processes, but struggle to set optimal conditions. As a result, they often experience product defects due to adhesion failures, unexpected production cost increases, and even delays in market launches. Optimized UV Curing is key to achieving quality improvement and cost reduction, but why aren’t we fully leveraging this opportunity? Huvics is here to provide the answer to this problem.

UV Curing, the Core of Advanced Industries and the Importance of Optimization

The Importance and Challenges of UV Curing and Its Optimization

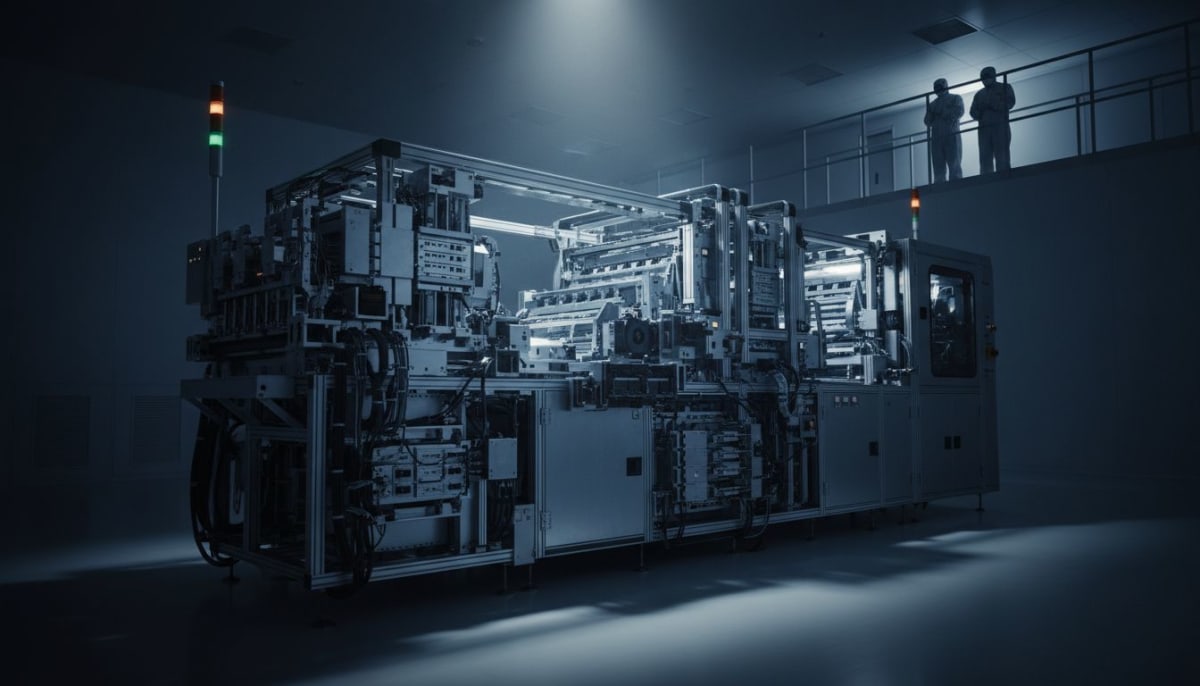

In the production of semiconductors or advanced electronic components, UV Curing, or ultraviolet curing technology, goes beyond being a mere step; it plays a pivotal role in determining the performance and lifespan of products. The synergy is maximized when this process is organically combined with other advanced equipment, such as laminator systems or cleaner systems.

The challenge lies in finding the optimal conditions for UV Curing, which depends on various variables. Only by meticulously adjusting factors like UV intensity, exposure time, and the properties of the curing material can you achieve the desired level of results. The difficulty in setting optimal conditions arises because even slight environmental changes can impact adhesive strength, durability, or even the defect rates of the entire process.

The Role of the Huvics Cleaner System

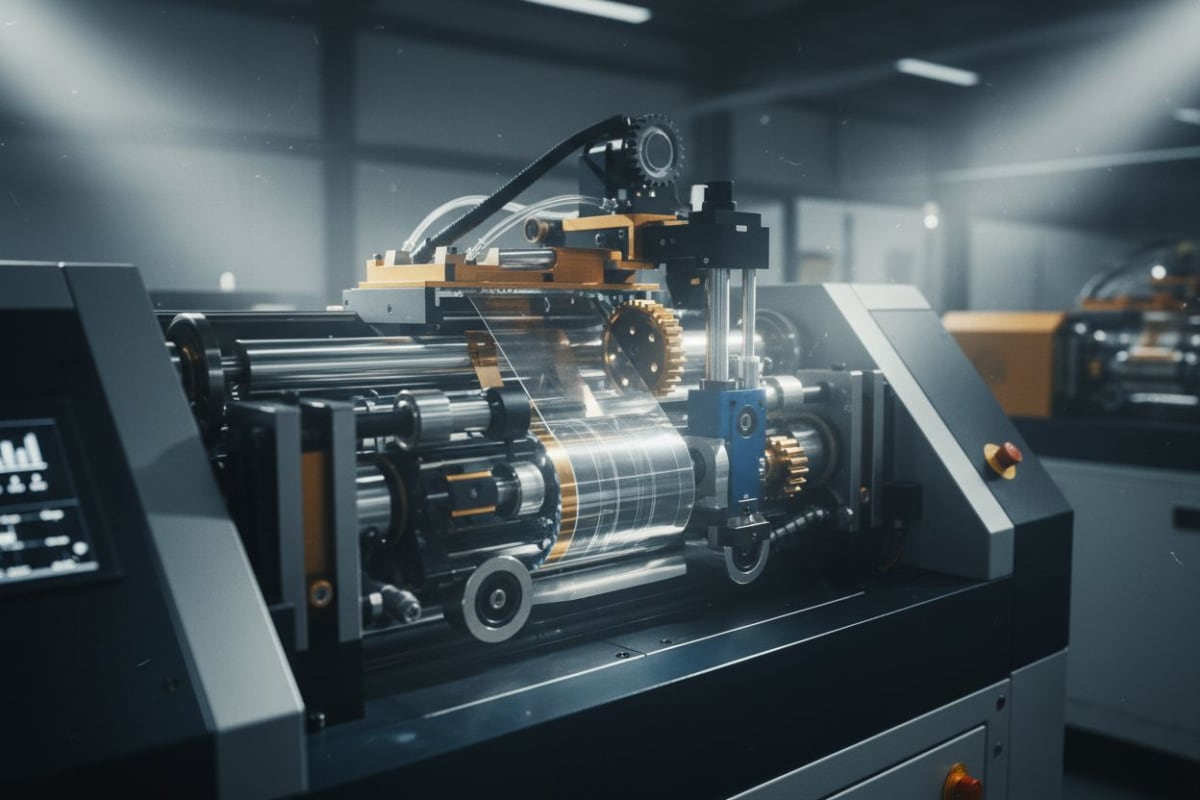

The Huvics cleaner system can decisively assist in setting optimal conditions for UV Curing by solving these challenges. Through multi-step cleaning technologies, such as microbubble, water jet, and air knife, the system creates the best environment for UV curing by thoroughly removing fine contaminants from the product surface. With such preparation, the potential of UV Curing can be fully harnessed, ultimately improving product quality and reliability.

Understanding UV Curing Technology and Huvics’ Tailored Solutions

Basic Understanding of UV Curing Technology

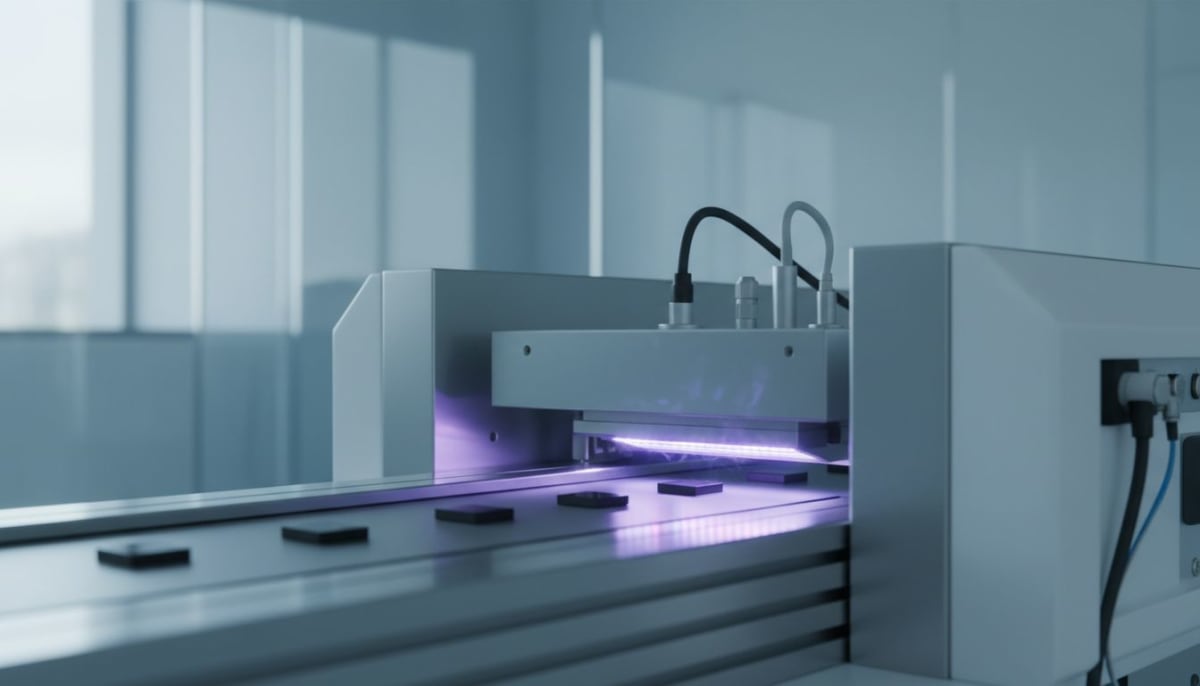

UV Curing technology is an innovative method that instantly transforms liquid materials into solid using ultraviolet light of specific wavelengths. Beyond merely setting adhesives or coatings, this technology significantly enhances the physical and chemical properties of cured materials, thereby greatly improving product performance and durability. In particular, precision adhesion and protective coating are essential in the production of advanced electronic components, and UV Curing fulfills these requirements, securing the reliability of the final product.

Integration with the Huvics Cleaner System

Recognizing the importance of UV Curing, Huvics integrates it into the cleaning processes of its cleaner system. By removing any microscopic moisture or residues that may remain on the product surface after cleaning through UV curing, it maximizes adhesive strength and secures process stability. This results in noticeably reduced defect rates and overall improved product quality.

UV Curing Methods and Tailored Solutions

There are mainly two UV Curing methods: UV lamp and LED. The UV lamp method is efficient for quickly curing wide areas at once, while the LED method offers optimized curing performance for specific materials with the added advantage of energy efficiency. Huvics meticulously analyzes diverse production environments and product characteristics to provide optimal UV Curing solutions tailored to the advantages of each method, actively supporting customers in enhancing production efficiency and developing innovative products.

Methods for Setting Optimal UV Curing Conditions and the Huvics Cleaner System

Importance of Finding Optimal Conditions

Finding the optimal conditions in the UV Curing process is crucial due to its immense impact on product quality and production efficiency. Without securing ideal curing conditions, issues such as adhesion failure, delamination, or degradation of surface properties can arise, compromising the reliability of the final product.

Methods for Adjusting Core Parameters

So how should you set these optimal conditions for UV Curing? This can vary finely depending on the product type, the properties of the UV curing substances used, and the desired final degree of curing. Generally, the optimal conditions are found by precisely adjusting UV lamp intensity (output), exposure time, and the distance between the product and UV lamp. These three core parameters are interconnected, meaning a change in one affects the others, requiring seasoned experience and accurate data analysis.

Optimization Through the Huvics System

Huvics’ Full Auto Cleaner System provides the outstanding advantage of automatically controlling these complex parameters and monitoring them in real-time. This maximizes production efficiency and maintains consistent quality while minimizing operator intervention. On the other hand, using Manual Cleaner Systems requires operators to finely adjust multiple variables, so accumulated expertise from long experience is even more crucial. Through these systems, Huvics contributes to achieving the ultra-precision processing and optimal process efficiency required in the semiconductor and advanced electronic component industries and supports successful business with custom equipment design and technical support reflecting customers’ specific needs.

Various Benefits of UV Curing Optimization and the Role of Huvics

Key Benefits of UV Curing Optimization

Setting optimal conditions in the UV Curing process is a key factor that not only enhances production efficiency but also determines the overall product quality, market competitiveness, and even the sustainability of the company. Huvics deeply recognizes the importance of UV Curing optimization and supports customers to achieve the best performance with this technology from multiple perspectives. The benefits gained from achieving optimal UV Curing conditions are indeed diverse.

- Noticeably enhance adhesive strength and significantly reduce process defect rates.

- Reduce production costs and greatly enhance overall productivity.

- Shorten curing process time and increase overall production efficiency.

- Secure flexibility to respond more quickly to market changes.

- Significantly reduce VOC emissions, enabling environmentally friendly production.

- Fulfill corporate social responsibility and secure sustainable growth competitiveness.

Application in Advanced Industries and Huvics’ Partnership

UV Curing technology offers broad advantages applicable to various materials and applications. Its application is particularly high in the semiconductor and advanced electronic component industries, which require ultra-precision processing, and it is essential for producing products with high reliability and precision. Huvics deeply understands the characteristics of these advanced industry fields and, through innovative technologies supporting productivity and yield improvements, assists customers in realizing the full potential of UV Curing and leading successful businesses as a trusted partner.

Ultimately, finding the optimal UV Curing conditions is more than just a step in the production process; it is a decisive factor in determining the reliability of the product and the competitiveness of the company. Understanding and controlling the subtle variables of the UV curing process can dramatically reduce defect rates, secure excellent adhesion strength and durability, and ultimately maximize production efficiency. Huvics will be a reliable partner on this complex optimization journey with its state-of-the-art cleaner systems and tailored solutions. Now is the time to realize the potential of UV Curing fully with a precise, data-based approach rather than random attempts.

Huvics is an advanced technology company that develops and manufactures automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries. With top talent and continuous technological innovation, we support customers in improving productivity and securing quality competitiveness.

Contact Info for Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com