Many advanced manufacturing companies strive for micron-level precision, yet lack confidence in the systematic sequence to fully realize the performance of a ‘high-precision stage’ as the core foundation. As a result, they often face setbacks due to minute defect rates, leading to unexpected production cost increases and losing competitive edge in next-generation product development in a rapidly changing market. Can you confidently say your production site is built on unwavering precision?

Importance of High-Precision Stage in Ultraprecision Processes

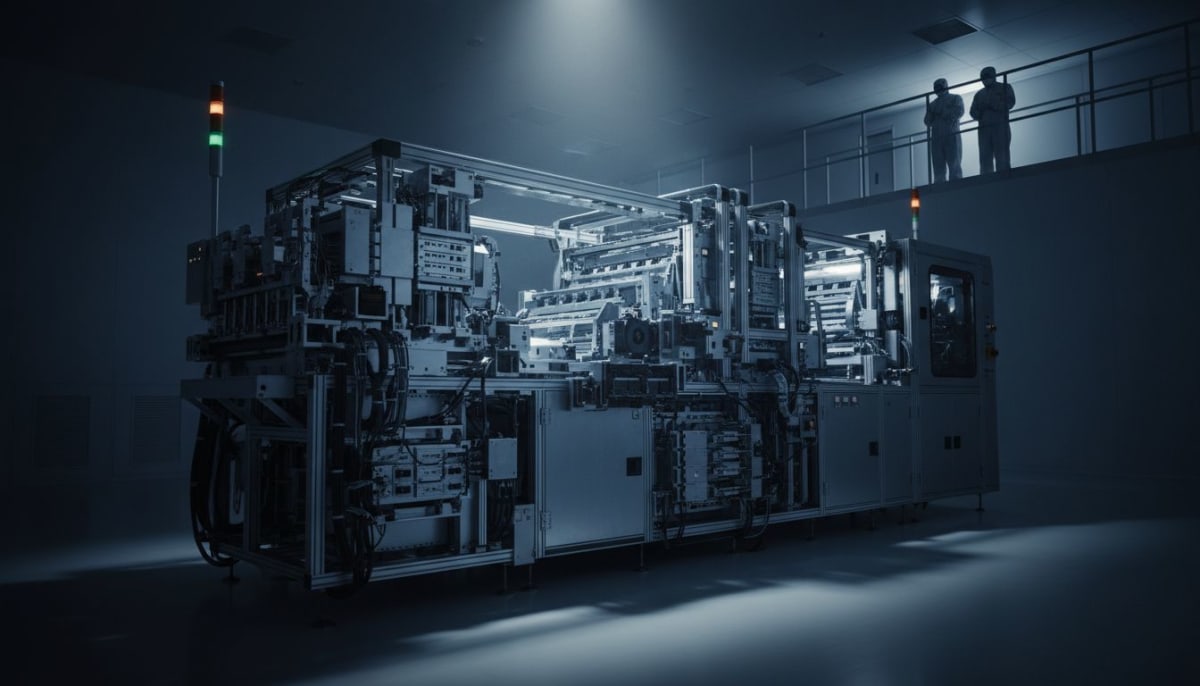

In high-tech industries, micron-level precision, which is difficult to distinguish with the naked eye, becomes an absolute standard that determines the success or failure of a product. Especially in ultraprecision machining and cleaning processes, success entirely depends on the performance of high-precision stages that control minute movements without error in unseen areas. These critical components not only support workpieces but serve as the fundamental foundation for creating perfect results, guaranteeing micron-level accuracy. What happens if the stage’s precision is lacking from the start? Regardless of how advanced subsequent machining technologies or equipment are applied, minute irregularities and errors will snowball, inevitably increasing the final defect rate. This is akin to a building collapsing if the foundation is weak, no matter how impressive the exterior may appear.

Role and Benefits of Huvics High-Precision Stage

Huvics understands this reality better than anyone and emphasizes that recognizing the role and importance of high-precision stages is the first step to achieving the perfect results we pursue. They believe that properly fastening the first button dictates the stability and efficiency of the entire process. Huvics’ high-precision stage focuses on removing all error factors customers may face in this first step. Equipment like Huvics’ PKG Grinder, through the combination of high-precision stages and diamond wheels, supports uniform and precise processing to the desired thickness and enables micron-level precision machining, providing drastic reduction in defect rates and maximization of quality stability of final products. This forms an important basis for reducing production costs and securing a competitive edge in the market.

In conclusion, Huvics’ high-precision stage is not just a component but a core foundation driving the success of the entire ultraprecision process for customers. By providing unwavering precision, Huvics helps ensure that customers achieve predictable and exceptional results in any challenging task. Under the belief that the performance of the high-precision stage directly correlates with product performance, Huvics consistently takes the most certain first step in ensuring customer success.

Precision Machining Technology of Huvics High-Precision Stage

In advanced industries, micron-level precision machining is more than just ‘good technology’; it is a key factor determining the final product quality and market competitiveness. So how does Huvics complete these standards of high-precision machining, and what is the process?

Robust Design and Vibration Minimization

The first step drawn by Huvics’ high-precision stage lies in ‘robust design that minimizes vibration’. No matter how excellent control technologies are, they are useless if the basic structure shakes. Just as skyscraper stability relies on a solid underground foundation, we lay an unshakeable base for precision machining through overwhelmingly durable design that doesn’t permit even sub-microscopic vibrations, serving as the reference point for all movements and providing reliability against any external impact.

Error Correction Through Feedback Control System

The second key step is ‘error correction through a feedback control system’. High-precision stages feature intelligent systems that detect and instantly correct even tiny errors occurring during the machining process in real-time. This is similar to a skilled artisan frequently checking and fine-tuning a workpiece. It allows for maintenance of targeted precision without deviation due to unexpected environmental changes or slight wear, providing predictable stability to production sites constantly battling variables. As a result, consistent quality can be anticipated even amidst uncertainties.

Perfect Synchronization with Precision Machining Tools

Finally, ‘perfect synchronization with precision machining tools like diamond wheels’ completes the value of Huvics’ high-precision stage. Even if elaborate movements are secured, the best results cannot be achieved without optimized tools to implement them. Huvics ensures that the fine control abilities of their high-precision stage are perfectly communicated to ultra-precise grinding tools like diamond wheels, moving as one, achieving micron-level machining goals.

The culmination of these phases shines in Huvics’ PKG Grinder. The ability to process advanced packages like FCBGA and WLCSP uniformly and error-free to the desired thickness results from the synergy of the principles of the high-precision stage and perfect ultraprecision grinding technology. Each precise movement becomes a key driver of consistent quality and high productivity in repetitive processes, leading to Huvics’ promise of enhanced final product quality stability and reduced defect rates.

Huvics Processing and Cleaning Solutions to Enhance Production Yield

In creating modern products, concentrated with cutting-edge technology, ‘precision’ stands as a crucial element over any other process. Especially, the introduction of high-precision stages becomes a decisive sequence that revolutionizes the production results rather than merely improving processes. Huvics’ high-precision machining systematically supports this crucial step, ensuring customer products achieve top-level performance and reliability.

Precision Machining of the PKG Grinder

Firstly, the micron-level thickness processing precision realized by Huvics’ PKG Grinder is directly linked to fundamental performance improvements in the products. The process of processing various advanced packages like FCBGA, WLCSP, QFN/DFN uniformly and precisely to the desired thickness is achieved by the perfect harmony of the high-precision stage and Diamond Wheel. This is similar to a surgeon’s precise hand movements in heart surgery, symbolizing the first and most important step in determining the quality of advanced electronic components. By significantly reducing defect rates through this machining, we can dramatically increase the completion of products proceeding to the next step.

Multi-Stage Cleaning of the Cleaner Machine

The role of the following Cleaner Machine is also maximized based on the stability of the high-precision stage. No matter how perfectly processed a product is, residual microscopic contaminants can cause overall performance degradation or errors. Huvics’ Cleaner Machine maximizes efficiency by thoroughly removing contaminants on surfaces of sensitive parts like camera modules and sensors through the convergence of multi-stage cleaning technologies like Micro Bubble, Water Jet, and Air Knife, relying on the unwavering movements of the stage. This goes beyond mere cleaning; it is a crucial second step blocking micro impurities that could affect the electrical or optical performance of the product at the source. Perfect cleaning performs a decisive role in significantly lowering defect rates and securing final product quality stability.

Consequently, these high-precision stage-based processing and cleaning solutions facilitate not only increased production yield but also perfectly meet the stringent specs demanded by customers, enabling successful mass production of various advanced packages. Huvics’ high-precision stage transcends being just a component and becomes the most certain and strategic investment for customers’ innovative product development and securing market competitiveness. By laying a high-performance foundation, customers can focus on developing next-generation products requiring more complex and minute technology, leading to market leadership and continued growth opportunities.

Systematic Management for Optimizing High-Precision Stage Performance

To fully realize the potential of high-precision stages and achieve innovative outcomes, a systematic approach is essential. Beyond simply introducing expensive equipment, optimizing precision at every stage of production and continuously managing it plays a crucial role. This is akin to a top chef meticulously managing every step from ingredient selection to cooking, and plating.

Selecting Stages Optimized for Production Environment

Firstly, carefully selecting high-precision stages that perfectly match the characteristics and purposes of the production line is essential. Since not all sites have the same requirements, flexible options are very important. Systems allowing flexible choice between Full Auto and Manual types, like Huvics’ Grinder System, provide optimized flexibility in rapidly changing production environments. By laying the foundation for ultraprecision grinding technology, they allow for processing to the desired thickness uniformly and precisely to achieve error-free micron-level results. This serves as a critical starting point for maximizing production efficiency from the initial setup.

Integrating Cleaning Strategies with Cleaner Machine

Next, focus on the cleaning strategy, an important process that determines the final quality of the product after ultraprecision machining. Because microscopic contaminants remaining on even the most intricately processed products can lead to overall performance degradation. Huvics’ Cleaner Machine flawlessly removes surface contaminants with multi-stage cleaning technologies like Micro Bubble, Water Jet, Air Knife, and Oven Dry functions, making it an essential step for fully realizing the potential of high-precision stages. It’s a necessary procedure for reducing defect rates and securing the final quality stability of sensitive and diverse products like camera modules, sensors, and VCM motors. The perfection of the cleaning process directly impacts product longevity and reliability, making it an unignorable crucial stage.

Management Strategy for Maintaining Continuous Performance

Lastly, a systematic management strategy to maintain the best performance and precision of high-precision stages must be established even after they are introduced. Regular inspections and calibration, as well as investments in controlling the optimal environment to prevent effects from minute environmental changes, should be supported. This extends beyond merely prolonging equipment lifespan to ensuring continued high-quality production, securing future technological competitiveness, and establishing an ultraprecision production environment that aligns with evolving industry standards. This ongoing effort forms the unchanging success foundation that Huvics promises to customers.

Ultimately, to fully realize the potential of high-precision stages and achieve innovative outcomes, a systematic approach that optimizes precision at every production stage and continuously manages it is essential, rather than relying solely on high-performance equipment. As Huvics suggests, all processes from selecting stages fitting the site perfectly, seamless cleaning, to continuous management strategies serve as the key to maximizing production efficiency and securing final product quality stability for customers. On this solid foundation, micron-level flawless results can be expected, becoming the most certain success strategy for maintaining a competitive advantage in the high-tech market.

Huvics is a high-tech company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support customers’ productivity improvement and quality competitiveness with top talent and continuous technological innovation.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com