Have you ever felt insecure holding your latest phone without a grip because of how slim it is? Many people share the worry of it slipping from their hands. How are such thin and sleek smartphones actually made? Today, we’ll delve into the secrets of how Huvics’ grinding-cleaning technology ensures the slimness of smartphones, with flexible applications through both Full Auto and Manual methods.

Smartphone Slimming with Huvics Grinder System

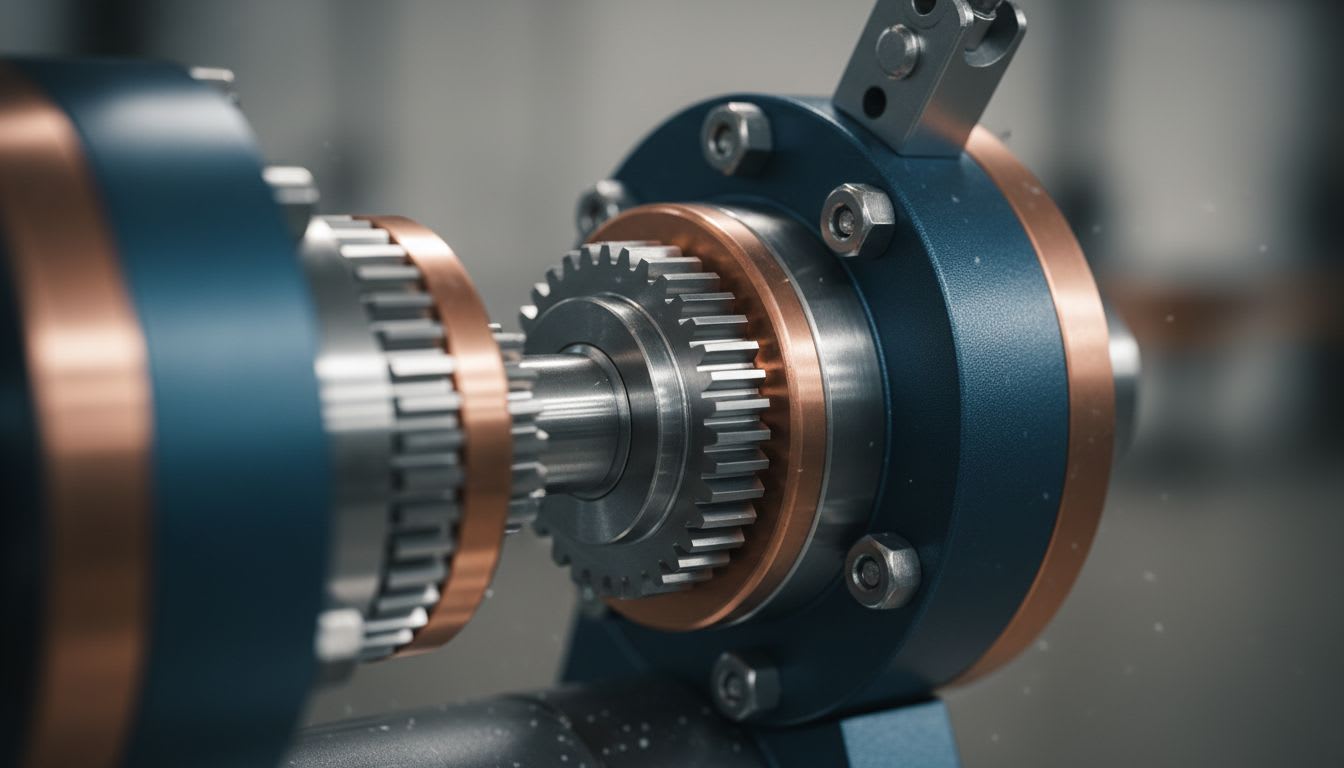

Ever wondered how smartphones have become impressively thin? Just a few years ago, they felt like bricks in hand, but now they have transformed into sleek and slim versions thanks to advances in cutting-edge technology. Specifically, ‘grinding’ technology has played a major role in precisely refining semiconductor chips to significantly reduce overall thickness. Traditional polishing methods had clear limitations in reducing chip thickness, which imposed constraints on smartphone design. However, innovative equipment like Huvics’ Grinder System has overcome these technical hurdles and opened up new possibilities.

The Core of Ultra-Precision Grinding Technology

Huvics’ Grinder System features ultra-precision technology that can grind the delicate chip surface down to a thickness thinner than a hair with no error. This makes Huvics’ Grinder System the hidden hero of smartphone evolution and a symbol of technological innovation. The major changes brought by this technology include:

- Significantly reducing the thickness of semiconductor chips, contributing to the slimming of smartphones

- Providing a foundation for manufacturers to realize thin and light smartphones

- Enabling overall innovation in finished smartphone products

- Offering users a comfortable and aesthetic smartphone experience

Flexible System Type Provision

Huvics offers Full Auto and Manual types of Grinder Systems tailored to various production environments, providing optimal solutions. Let’s now take a deeper look into the next step in surface cleaning technology, which elevates the quality of smartphone components to a new level.

Enhancing Smartphone Quality with Huvics Cleaner Machine

Multi-Stage Cleaning Technology to Remove Contaminants

Another hidden hero that makes smartphones thinner and last longer is surface cleaning technology. Huvics’ Cleaner Machine showcases unparalleled technological prowess in this field, elevating the quality of smartphone components. Internal smartphone components are highly sensitive to even minute dust or foreign substances; such contamination can lead to reduced product performance, shortened lifespan, and even critical defects. To solve these issues, Huvics’ Cleaner Machine integrates multi-stage cleaning technologies like micro bubbles, water jets, and air knives to perfectly remove even the smallest contaminant particles on component surfaces. Especially with parts like camera modules or precision sensors where even a tiny error is intolerable, it shows its true worth and helps smartphones perform optimally.

Oven Drying Function and Integrated Solution

Another significant differentiating factor of Huvics’ cleaner machine is its ‘Oven Dry’ function. The remaining moisture after cleaning can lead to corrosion or electrical errors in components, but Huvics prevents these potential risks at their root through a perfect drying process. This plays a decisive role in remarkably reducing defect rates due to moisture and maximizing the quality stability of the final product. Such an integrated cleaning-drying process ensures a level of cleanliness and stability that would have been difficult to achieve with conventional simple cleaning methods, maximizing the potential of internal smartphone components to enhance the overall completeness. By offering Full Auto and Manual types tailored to customers’ production environments and requirements, Huvics provides robust support to smartphone manufacturers in achieving competitive edges and successfully producing innovative products.

Semiconductor Package Ultra-Precision Processing, Huvics PKG Grinder

Core Role of PKG Grinder

Another core technology that enables both the slim design and high performance of smartphones is Huvics’ PKG Grinder. It is essential not only to reduce the thickness of semiconductor chips but also to drastically reduce the thickness of the ‘package’ that protects these chips to create even thinner smartphones. The main roles of the PKG Grinder include:

- Processing semiconductor packages to a micron degree, enhancing internal space efficiency

- Allowing more functionality integration and achieving sleek smartphone designs

Ultra-Precision Processing Technology

PKG Grinder realizes an ultra-precision process that was once hard to imagine with conventional grinding methods. Its core technological strength lies in uniformly grinding various forms of semiconductor packages like FCBGA (Flip-Chip Ball Grid Array), WLCSP (Wafer Level Chip Scale Package), QFN/DFN (Quad Flat No-leads/Dual Flat No-leads) to the specific thickness that customers require. A high-precision stage securely holds the package with no movement, and a specially designed diamond wheel precisely processes delicate parts ensuring error-free grinding accuracy. This micron-level precision processing plays a critical role in maximizing the performance of semiconductor chips, aiding smartphones in operating faster and more efficiently. Through PKG Grinder, Huvics is continuously committed to broadening the limits of semiconductor technology, enabling smaller yet more powerful semiconductors to make our lives more convenient and enriched.

Huvics Grinding-Cleaning Technology Synergy Effects

The unseen innovative technologies have worked hard to allow today’s smartphones to boast a design that’s incredibly thin and sophisticated compared to the past. Particularly, Huvics’ grinding-cleaning technology has played a crucial role in making smartphones thinner, more efficient, and ultimately more perfect in terms of product. At the heart of this innovation is the integrated connection of the three key pieces of equipment provided by Huvics.

Summary of Key Equipment Roles

The roles of each piece of equipment are as follows:

- Grinds chips with ultra-precision in Full Auto and Manual types to reduce smartphone thickness

- Employs multi-stage cleaning technology to remove chip surface contaminants, reduce defect rates, and ensure quality stability

- Precisely processes various semiconductor packages down to the micron level, contributing to performance enhancement

Customized Solutions and Synergy

The meticulous combination and mutually complementary operations of these three Huvics technologies enable the production of thin and precise smartphones, which would have been difficult to achieve with traditional manufacturing methods. In addition to offering cutting-edge equipment, Huvics goes beyond by providing customized solutions tailored to the unique production environments and goals of each client, raising production efficiency and proactively supporting smartphone manufacturers in successfully developing innovative products that lead the market.

Contribution to Future Technology Innovation

Ultimately, Huvics’ technology is not just about reducing the physical thickness of smartphones, but also enhancing user experiences and being a vital driving force for future technology innovation.

Beyond the slim smartphones we hold today, what kind of innovations will future technology bring? Huvics’ ultra-precision grinding and cleaning technology goes beyond merely reducing the thickness of chips and packages, offering optimal solutions tailored to each production environment under the options of Full Auto and Manual, maximizing device performance and stability. This technological evolution will be a key driving force opening new horizons for user experiences that future smartphones will deliver.

Huvics is an advanced technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

By leveraging top-tier talent and continuous technological innovation, we support clients in enhancing productivity and securing quality competitiveness.

Huvics Co., Ltd. Contact Information

Phone: 031-374-8285

Email: cdpark@huvics.com