The process of extending the lifespan of semiconductors through cleaning equipment is akin to the regular, meticulous maintenance of a luxury watch. Just as minute invisible contaminants or tiny inconsistencies in parts threaten the accuracy and longevity of a watch, similarly, semiconductors often fail to realize their full potential when faced with these unseen adversaries. However, much like a watch being reborn under the skilled hands of an artisan, semiconductors gain new vitality through precision cleaning technology, escaping the cycle of performance degradation. How did Huvics address this longstanding challenge for semiconductors and script a story of dramatic change in their lifespan?

The Main Culprits Behind Shortened Semiconductor Lifespan: Micro Contaminants and Irregularities

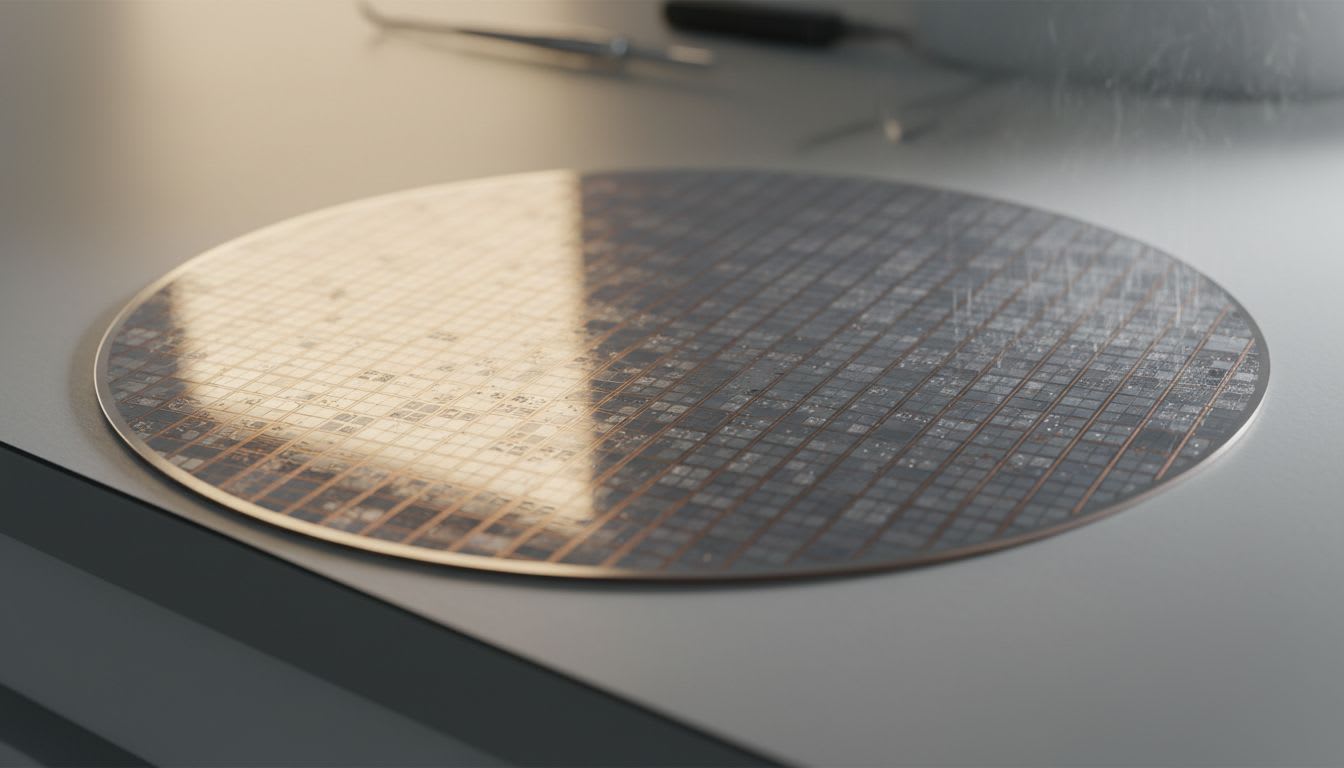

Semiconductors have always aspired to peak performance, and the industry has relentlessly pursued miniaturization and sophistication. Yet, an invisible shadow has persistently loomed over this journey of aspirations.

No matter how intricately designed a chip is, it must confront the profound challenge of minuscule contaminants, almost undetectable to the naked eye, or unseen thickness inconsistencies. Just as a tiny dust particle could disrupt the core operation of a sophisticated machine, residues from the manufacturing process seep into a chip or subtly alter surface tension, repeatedly leading to unexpected performance drops and premature failures. These factors have been the biggest obstacles preventing semiconductors from fully realizing their infinite potential and shortening their lifespan.

Deeply understanding these longstanding issues faced by semiconductors, Huvics began to navigate through these challenges as if breathing new life into semiconductors with its precision cleaning and grinding technology. By perfectly removing the microscopic contaminants that devoured lifespan and precisely smoothing out the uneven thicknesses, Huvics opened the path for semiconductors to showcase their intrinsic value and perform optimally for much longer periods.

Huvics’ Multi-Step Cleaning Technology for Perfect Micro Contaminant Removal

Removing micro contaminants that shorten semiconductor lifespan has been a longstanding challenge in the industry. Initially, visible cleanliness was satisfactory, but as circuit line widths became extremely narrow, simple cleaning methods reached their limits. Consequently, the industry began to focus beyond ‘cleanliness’ to ‘perfection’ in contamination control, and Huvics embarked on a journey to meet these pressing demands by maximizing semiconductor potential. Huvics implemented the following multi-step cleaning technology:

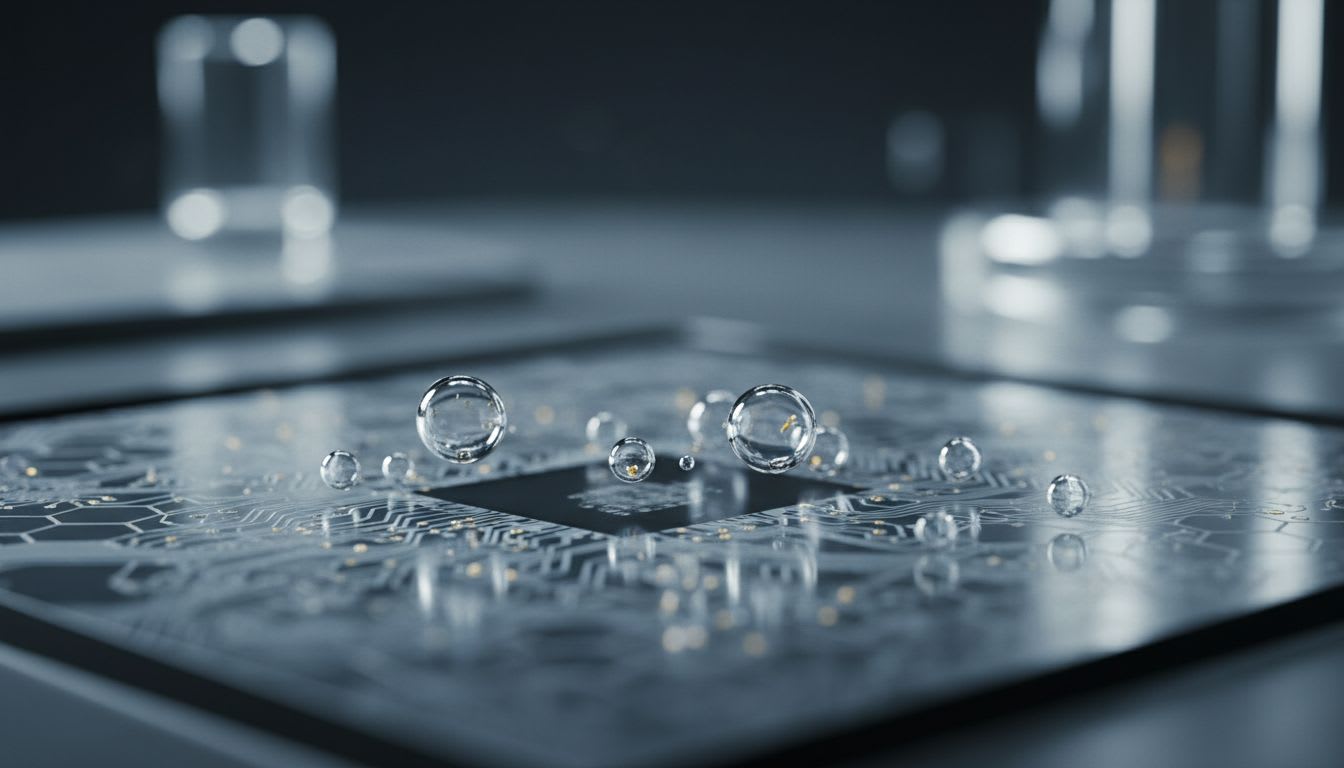

- Complete removal of contaminants using multi-step cleaning technologies including micro bubbles, water jets, and air knives

- Implementation of an oven dry feature that leaves no trace of moisture

This became the essential key to dramatically reducing defect rates and securing final product quality stability, allowing for a significantly longer semiconductor lifespan.

Maximizing Physical Stability with Ultra Precision Grinding Technology

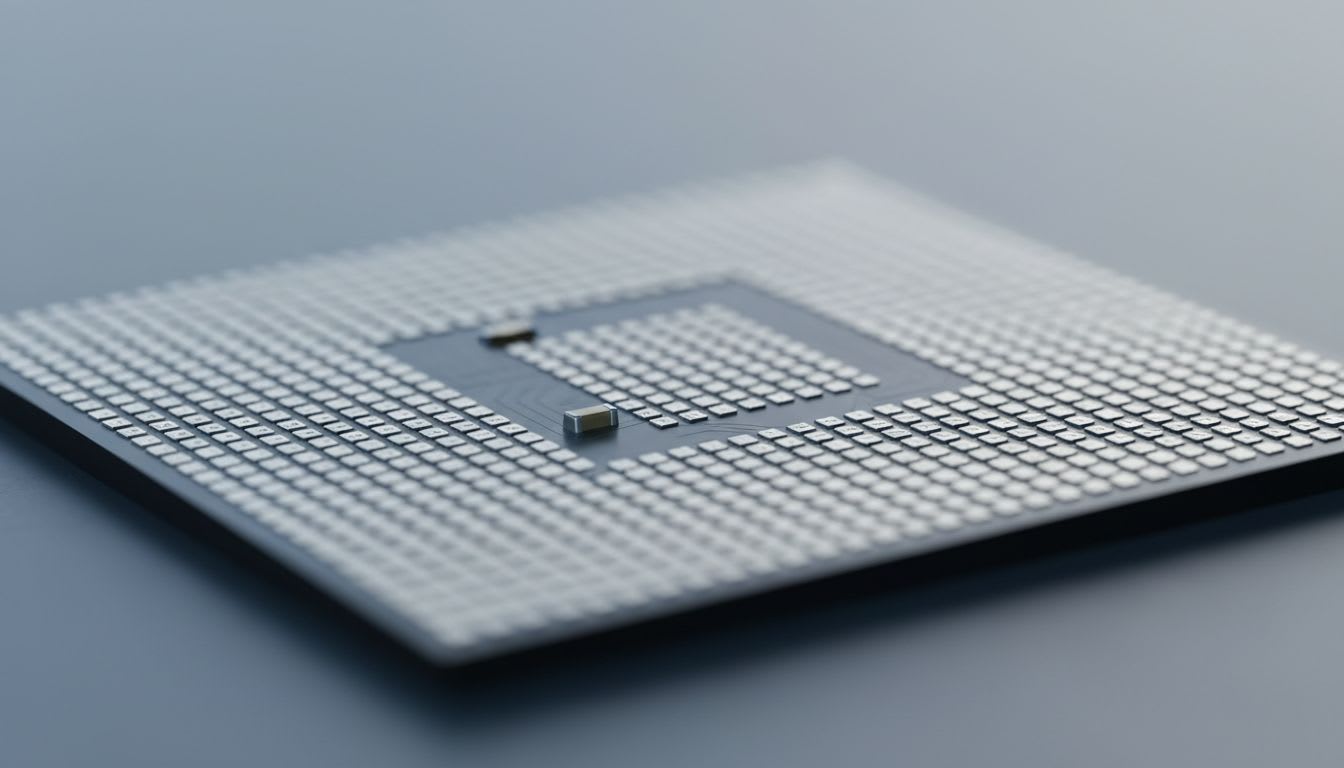

Beyond the removal of micro contaminants, another key factor determining the lifespan of semiconductors is physical stability. Physical defects that lead to chip performance degradation and failure have long been fundamental obstacles blocking breakthroughs in advanced semiconductors. Faced with these challenges, Huvics sought fundamental solutions that went beyond mere surface cleanliness to maximize the chip’s physical stability itself. Huvics’ innovative cleaning and grinding equipment maximizes physical stability in the following ways:

- Complete removal of contaminants through the multi-step cleaning technology and oven dry function of cleaner machines

- Precision machining of various packages using a grinder system with ultra precision grinding technology

- Machining to uniform thickness in micron units as desired by customers to maximize physical stability

Through these integrated efforts, Huvics firmly commits to maximizing the potential of semiconductors and fully enjoying their lifespan.

A New Standard for the Semiconductor Industry Brought by Huvics Solutions

For this reason, semiconductors have often struggled to fully realize their potential due to invisible adversaries such as micro contaminants and uneven processing, which critically affected the reliability of the final products. However, the solutions integrated with Huvics’ ultra-precision grinding technology and multi-step cleaning technology provided a clear answer to these longstanding challenges. The introduction of precision cleaning and processing technology set a new standard in semiconductor manufacturing processes and brought about remarkable changes. As a result, defect rates significantly decreased, and product quality stabilized, allowing semiconductors to now fully leverage their potential and achieve a much longer and more stable lifespan. Huvics is at the heart of this change, illuminating the future of the semiconductor industry.

Even semiconductors packed with numerous advanced technologies have faced fundamental problems of not fully realizing their potential and having their lifespan shortened due to invisible micro contaminants and imperfect processing. Moving beyond merely chasing functionality, the path to true innovation may have been ensuring that semiconductors reveal their intrinsic value and maintain a trusted lifespan over an extended period. Huvics focuses precisely at this point, drawing out the hidden potential of semiconductors through precision cleaning and grinding technology, and breaking down the barriers of imperfection, becoming the trustworthy partner breathing more stable and longer life into them.

Huvics is a high-tech company that develops and manufactures automation equipment and production systems across industries such as semiconductors, LED, mobile, and cosmetics.

With top-notch personnel and continuous technological innovations, we support improving customer productivity and securing quality competitiveness.

Huvics Co., Ltd. Contact

Phone: 031-374-8285

Email: cdpark@huvics.com