According to a recent industry report, more than 80% of technical designers in the development and operation of precision grinder systems identified ‘maintaining precision’ and ‘processing composite materials’ as their biggest challenges. This highlights the intense real-world hurdles faced by technical designers in ultra-precision environments, where even micron-level errors, equating to fractions of a hair’s thickness, are unacceptable. Huvics understands these deep concerns and aims to provide solutions that go beyond the equipment to address these genuine issues faced by designers.

Core Challenges in Ultra-Precision Machining and Huvics’ Solutions

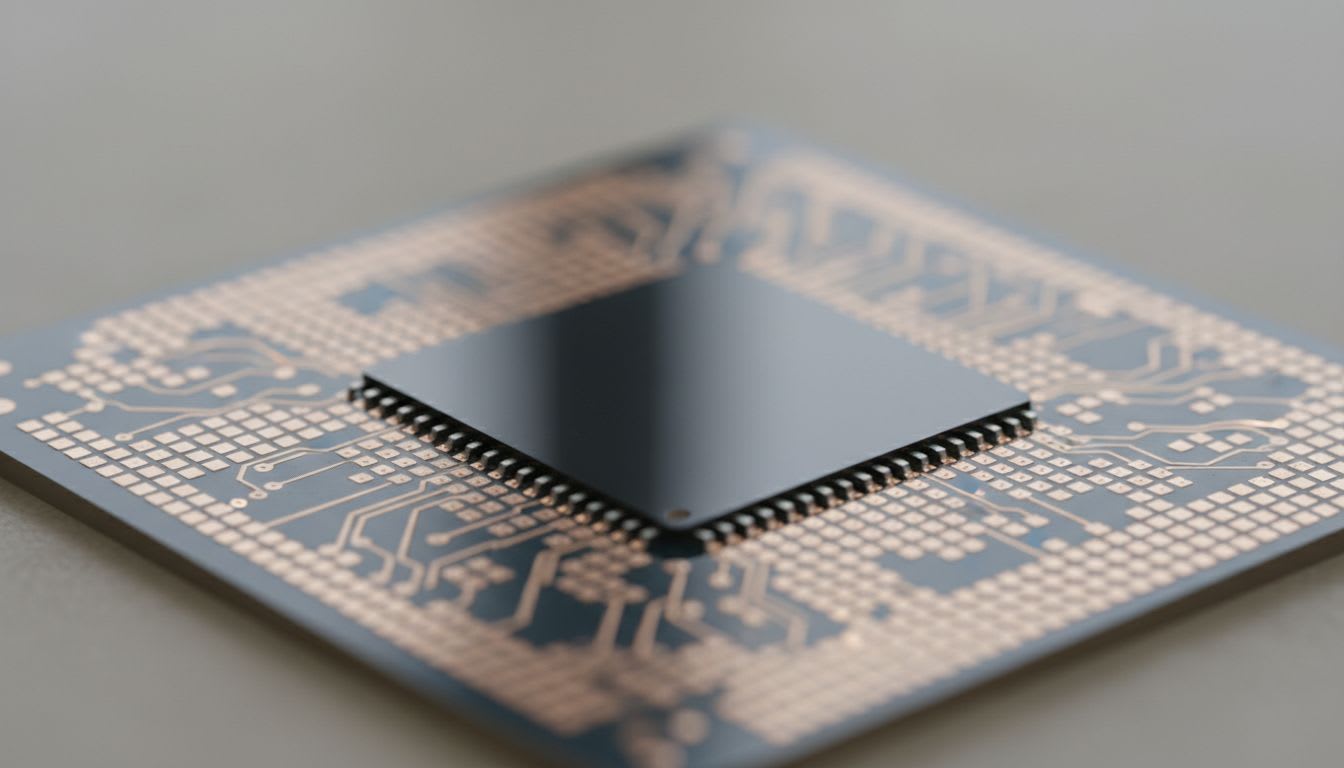

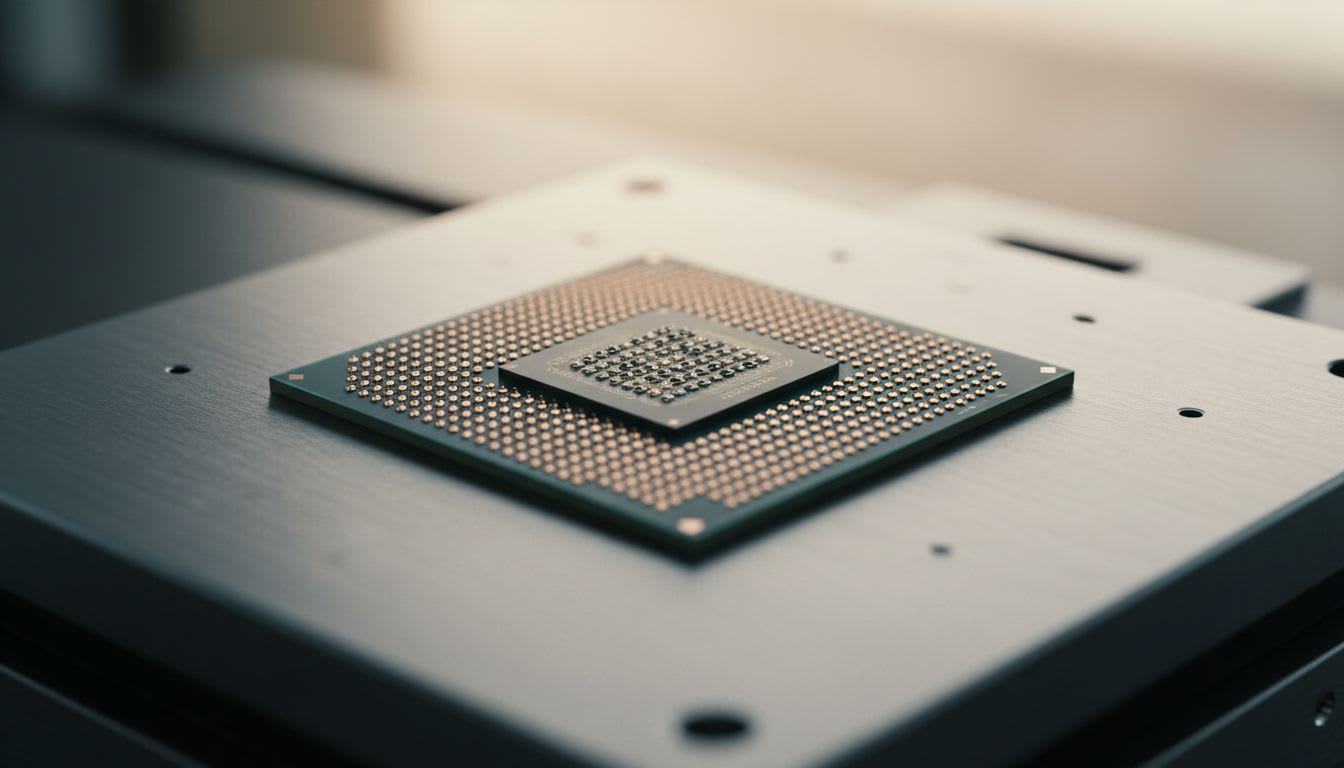

In the realm of ultra-precision machining, grinder systems are more than just machines that trim materials. They are arenas of extreme precision, comparable to shaving hair under a microscope, as any technical designer will attest. Especially, ultra-precision grinding equipment like the PKG Grinder aims for micron-level accuracy, not allowing deviations equating to fractions of hair thickness. This high level of target accuracy becomes a fundamental challenge generating numerous technical hurdles from the design’s inception.

Challenges in Handling Composite Materials and Packages

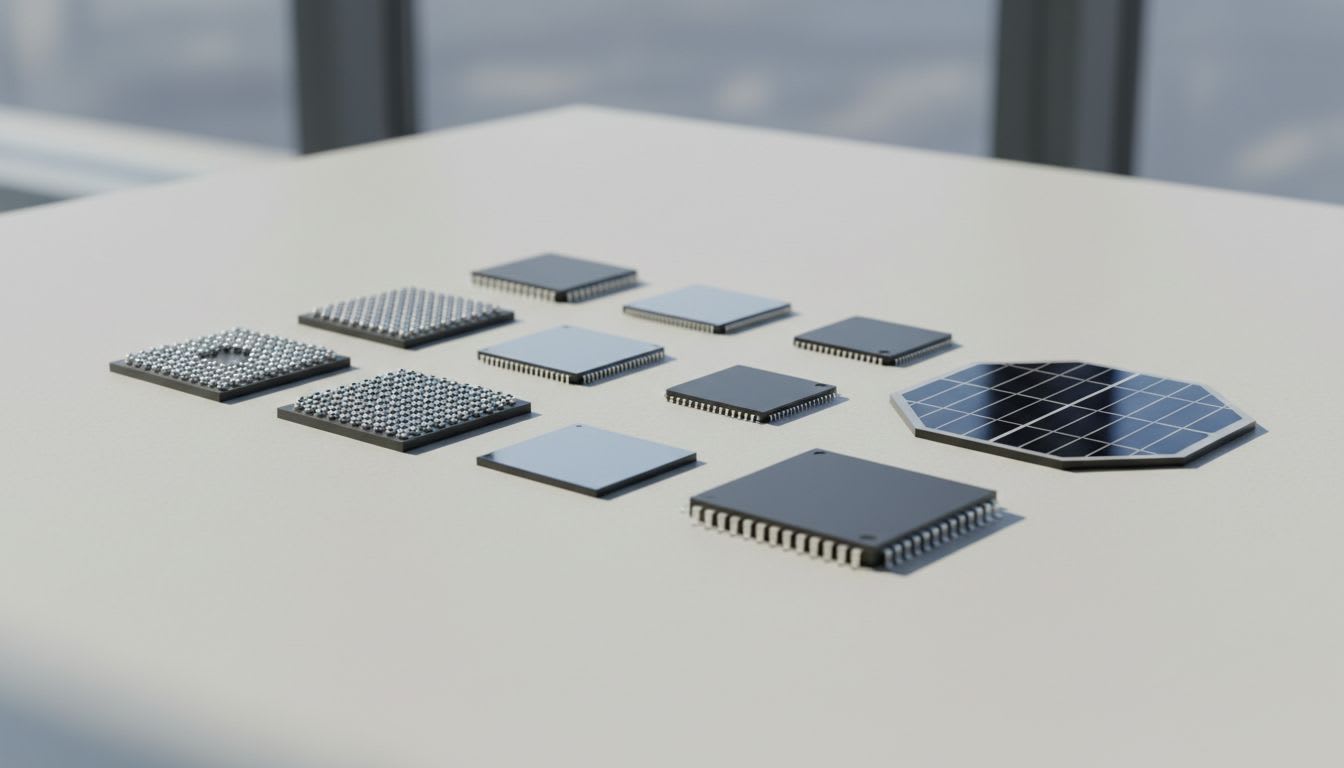

Beyond merely achieving uniform thickness, designers must consider various package types like FCBGA, WLCSP, QFN/DFN, and Solar Cell along with their distinct physical properties such as hardness, thermal expansion coefficients, and brittleness which directly affect precision. For instance, some materials may react sensitively to heat, deforming with minute temperature changes. Designers grapple with these myriad variables constantly, leading to their ‘endless battle with precision’—a fundamental challenge.

Huvics PKG Grinder’s Precision Solutions

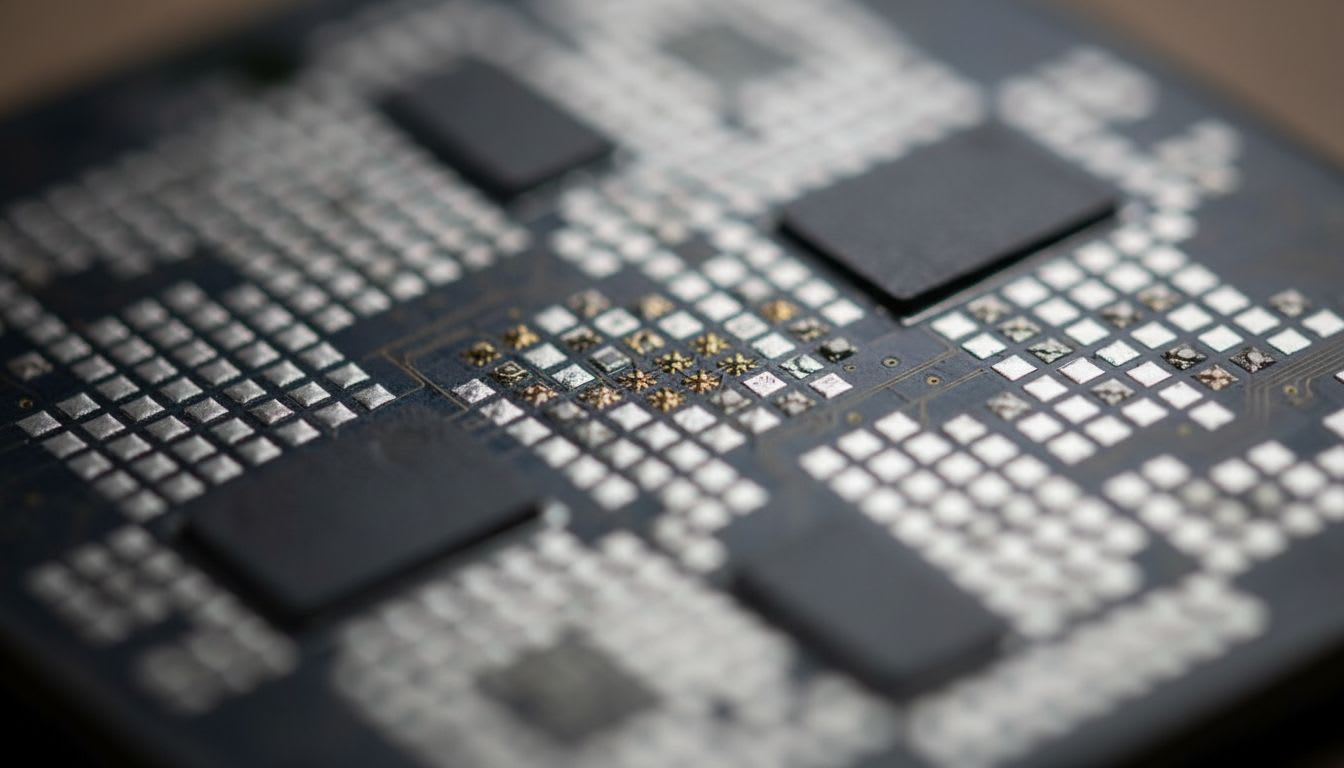

Huvics deeply understands the challenges designers face in pushing the limits of precision. Utilizing high-precision stages and diamond wheels as core technologies, the PKG Grinder perfectly balances material characteristics and package diversity, ensuring uniform thickness without error as desired by clients. This underscores Huvics’ commitment, beyond just supplying machinery, to resolving deeper issues requiring extreme precision, establishing it as a reliable partner for technical designers.

Challenges in Environmental Changes and Operational Flexibility

Maintaining Precision Amidst Environmental Variations

Designers of grinding systems face countless technical challenges within the complex process of ‘ultra-precision grinding’, beyond simply achieving high precision. High-precision stages and diamond wheels enabling micron-level processing are extremely sensitive to micro-vibrations, unpredictable wear, and surrounding temperature changes, making their maintenance in perfect condition challenging. It’s akin to constructing a skyscraper able to withstand slight earthquakes, representing one of the realistic daily concerns faced by designers.

Ensuring Stability During Operational Mode Transitions

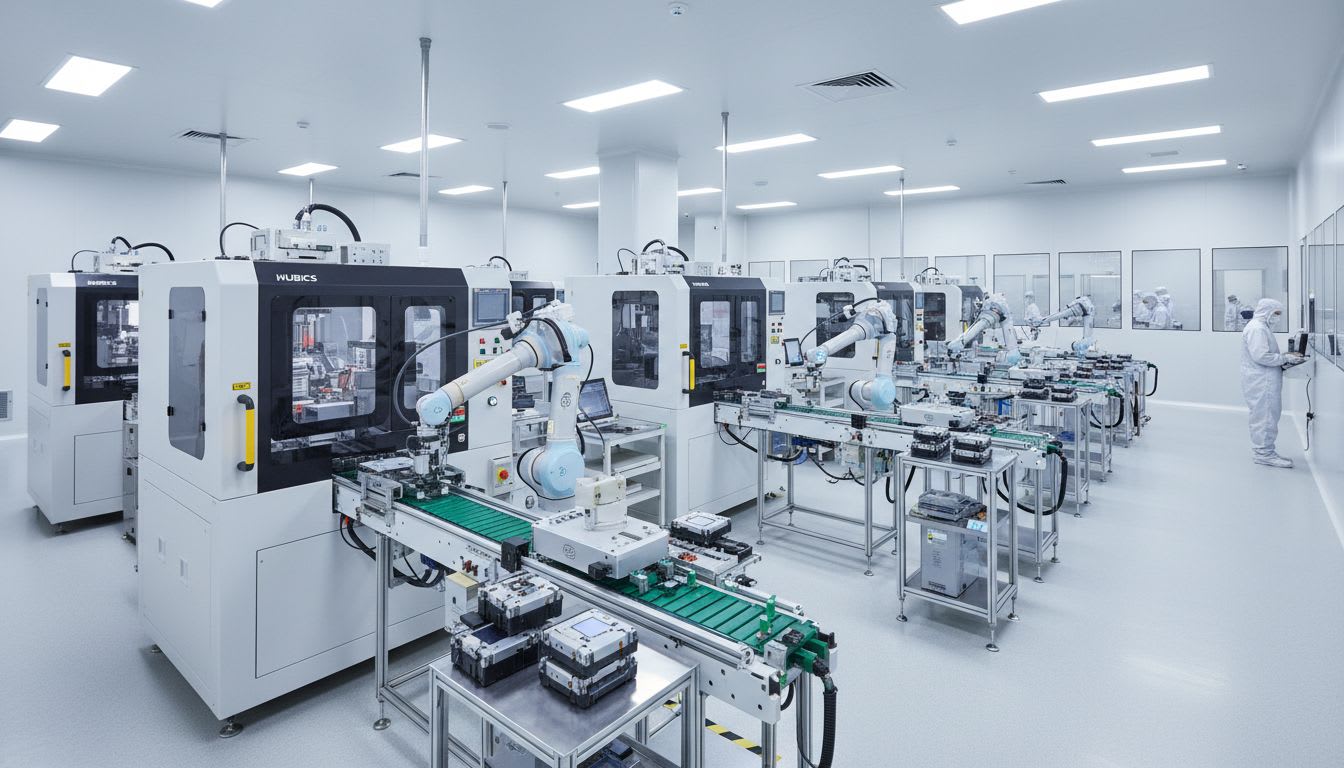

Furthermore, configurations like Full Auto and Manual Types for flexibility in production may appear convenient, but minimizing minute errors during mode transitions, maintaining consistent quality at every process stage, and ensuring continuous equipment stability remain constant challenges for designers. The gap between ideal specs and actual operating variables becomes the true challenge and crucial factor for high-quality production as cited by technical designers.

Huvics’ Integrated Technical Solutions

Huvics deeply understands these challenges and focuses beyond merely providing equipment to solving precise grinding challenges. Huvics aids clients in drastically reducing defect rates and ensuring unwavering product quality through technologies such as:

- Designs resilient against micro-vibrations and thermal variations to ensure equipment stability

- Minimizing error during automatic/manual mode transitions to ensure productivity

Through these technical solutions, Huvics provides an environment for designers to focus solely on developing innovative products, supporting them in overcoming the limits of ultra-precision machining.

Cleaner Machine Solutions for Ensuring Post-Process Quality

Issues of Contamination and Quality Deterioration Post-Grinding

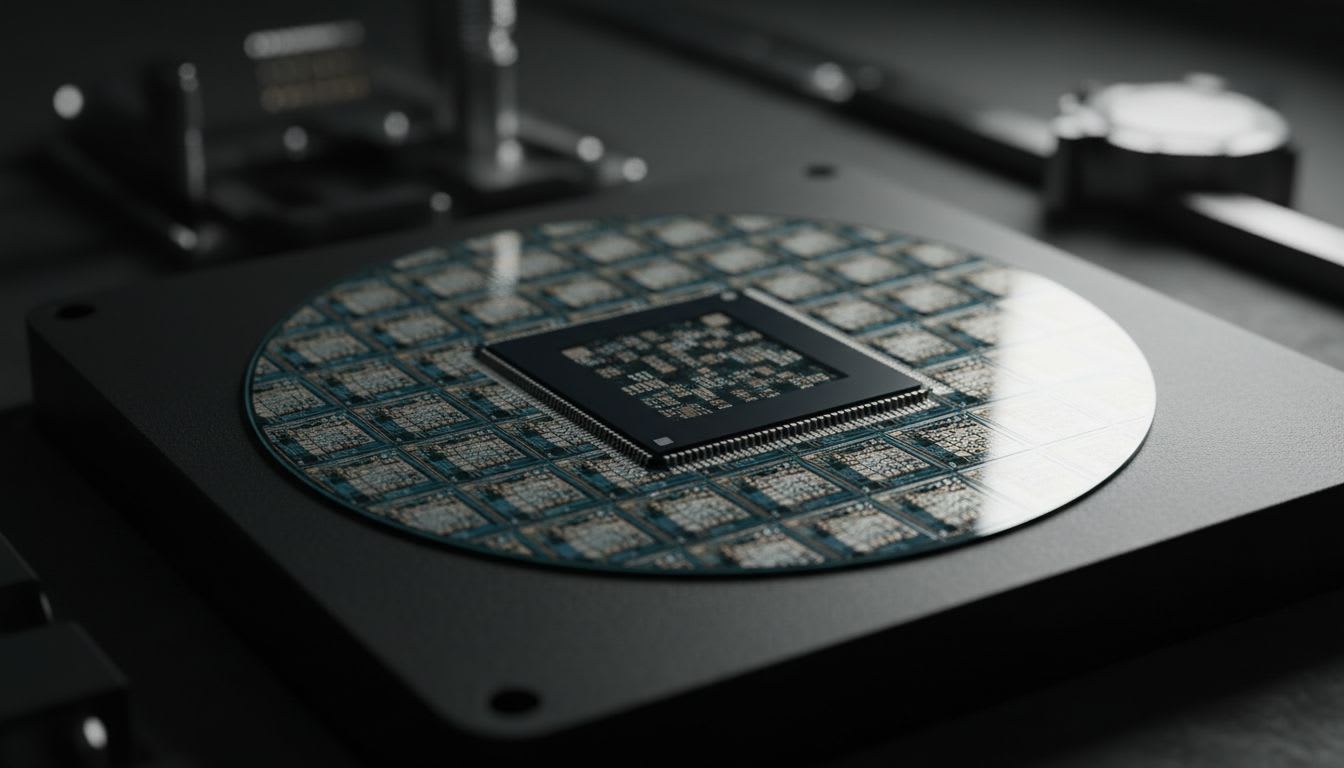

The challenges faced by technical designers in grinding surpass mere grinding processes, impacting subsequent process quality and introducing complex system-wide hurdles. Microparticle contamination or surface damage inevitably produced during grinding directly increases defect rates in final products. Like a poorly fastened button ruining the entire outfit, small issues from the grinder significantly escalate final product defect rates. To provide a clear resolution to such problems, Huvics offers a vital companion—the Cleaner Machine—to complement the grinder process boundaries.

Core Technologies of Huvics Cleaner Machine

Huvics Cleaner Machine integrates multi-stage cleaning technologies like microbubble cleaning, water jets, and air knives to completely remove contaminant particles from product surfaces. Especially for ultra-precision parts like camera modules, sensors, and VCM motors, where even minor contamination is unacceptable, achieving perfect surface condition is both a fierce effort and essential task for designers. Additionally, the oven dry function blocks issues like moisture retention post-cleaning, ensuring perfect drying and elevating final product stability and reliability.

Optimizing Production Systems with Integrated Solutions

Ultimately, challenges in grinder systems transcend individual equipment performance, requiring organically controlled, highly intricate production systems. By integrating ultra-precision grinding technology-based grinder systems with advanced cleaner machines, Huvics maximizes particle removal efficiency, contributing to defect reduction and ensuring final product quality stability in client operations. This demonstrates Huvics’ firm commitment to offering integrated solutions surpassing simply supplying equipment, covering every step of precision production systems comprehensively.

Huvics’ Integrated Solutions and Vision for the Future

Innovation Drives through Technological Convergence

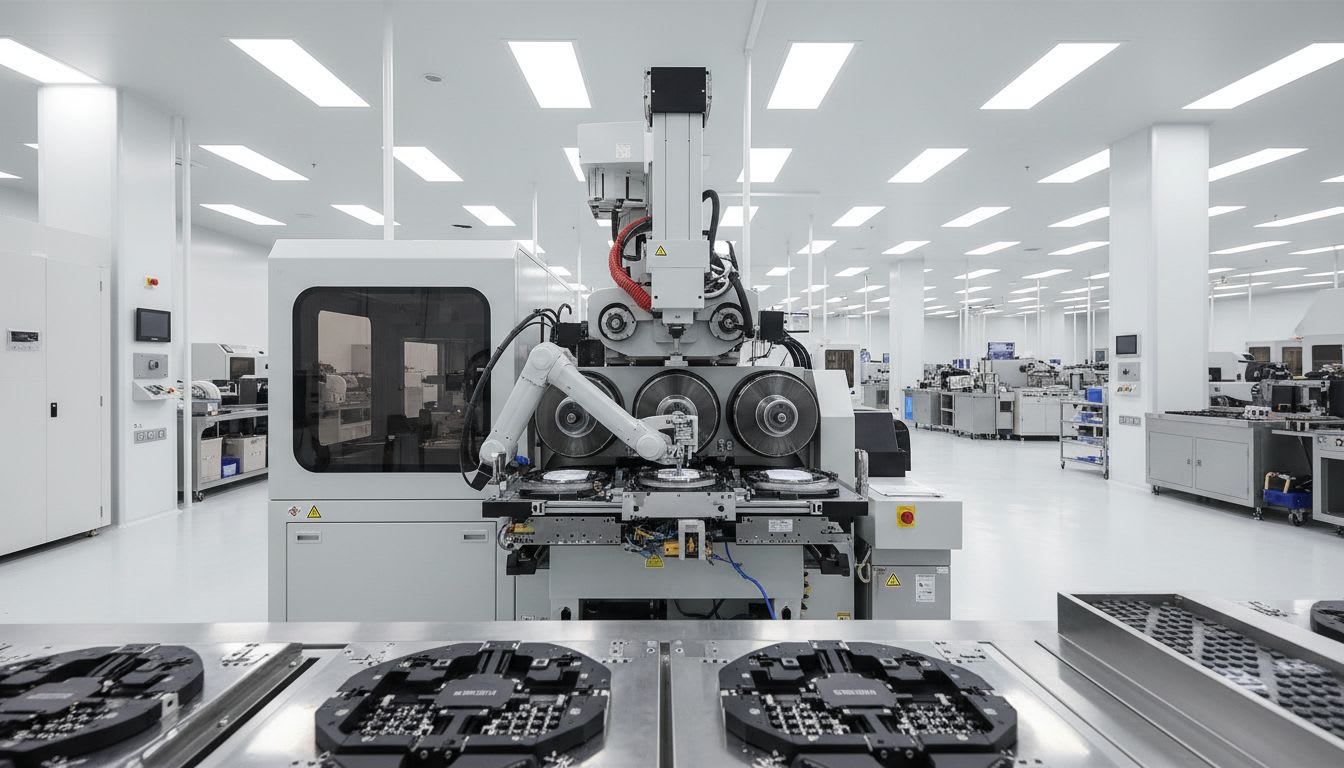

The challenges posed by grinders for technical designers are not merely hurdles to avoid. Instead, they have been powerful drivers accelerating technological advancement and fostering innovation toward a better future. To elevate the equipment’s stability and efficiency, given its complex and nuanced characteristics to the highest levels, Huvics actively seeks technology convergence across diverse fields, from in-depth materials science understanding to automated controls and AI-based predictive maintenance.

Integrated Value of Huvics Solutions

Huvics’ grinder systems, based on ultra-precision grinding technology, provide flexible automatic and manual configurations optimal for client production lines. Combining high-precision stage and diamond-wheel technology, the PKG Grinder—an ultra-precision grinding equipment model—perfectly achieves extreme precision, processing various packages such as FCBGA, WLCSP, QFN/DFN, and Solar Cells to customer-desired micron levels. Additionally, the Multi-Stage Cleaning Technology of Cleaner Machine with elements like Micro Bubble, Water Jet, and Air Knife along with Oven Dry function achieve perfect synergy, drastically reducing defect rates and guaranteeing final product quality stability by fully removing micro-contaminant particles from product surfaces.

Vision for an Intelligent System Future

Ultimately, future grinder systems will surpass mere processing devices. Huvics envisions grinders evolving into truly intelligent systems, actively interacting with their environment and autonomously maintaining optimal status. In this transformative process, technical designers may continuously face new challenges, yet this will inevitably become an essential part of Huvics’ journey toward higher precision and reliability. Beyond solving issues, Huvics aims to offer differentiated value and a vision for future production environments realized through state-of-the-art technology.

The challenges technical designers face with grinders in ultra-precision machining are certainly complex challenges demanding both micron-level precision and process stability. Understanding these deep concerns, Huvics integrates extreme precision grinding technology of PKG Grinder with the perfect contaminant removal solution of Cleaner Machine to drastically lower defect rates and ensure final quality stability on-site. This provides an environment for technical designers to focus solely on innovative product development, opening new horizons in precision machining’s future, partnered with Huvics.

Huvics is a high-tech company developing and manufacturing automation equipment and production systems across Semiconductor, LED, Mobile, and Cosmetic industries.

With the best personnel and continuous technological innovation, we support enhancing productivity and securing quality competitiveness for our clients.

Huvics Co., Ltd. Contact

Phone: 031-374-8285

Email: cdpark@huvics.com