When we think of ‘automation’, it often conjures up magical scenes where everything runs smoothly on its own. Robots making coffee, cleaning robots shining up the house, and so on. However, reality often hits with a sigh of ‘I thought it would be automated, but it’s more complicated now.’ Especially in semiconductor production lines, this ‘smooth automation’ is impossible without advanced technologies. How is Huvics making the impossible possible in a world where even minute invisible errors must be controlled perfectly to be called true automation?

Semiconductor Production Line Automation: More Than Just a Replacement

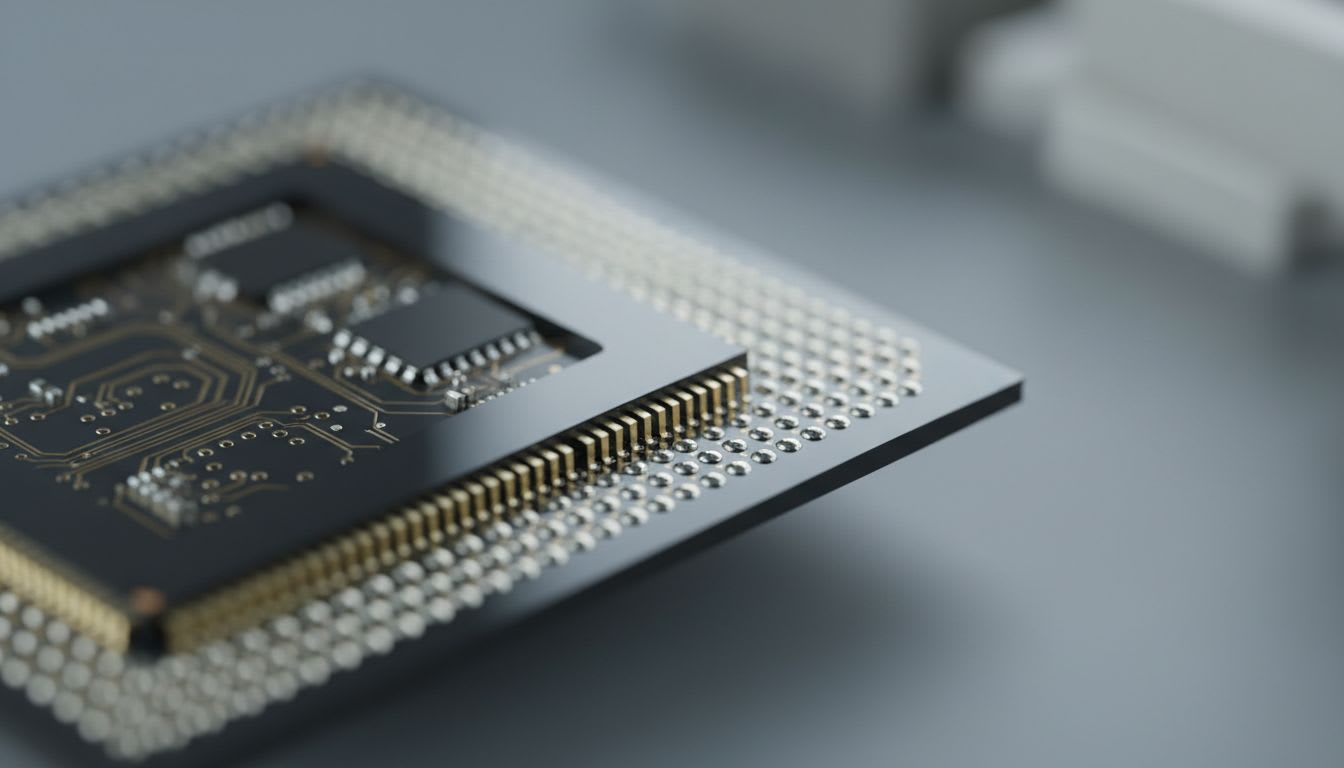

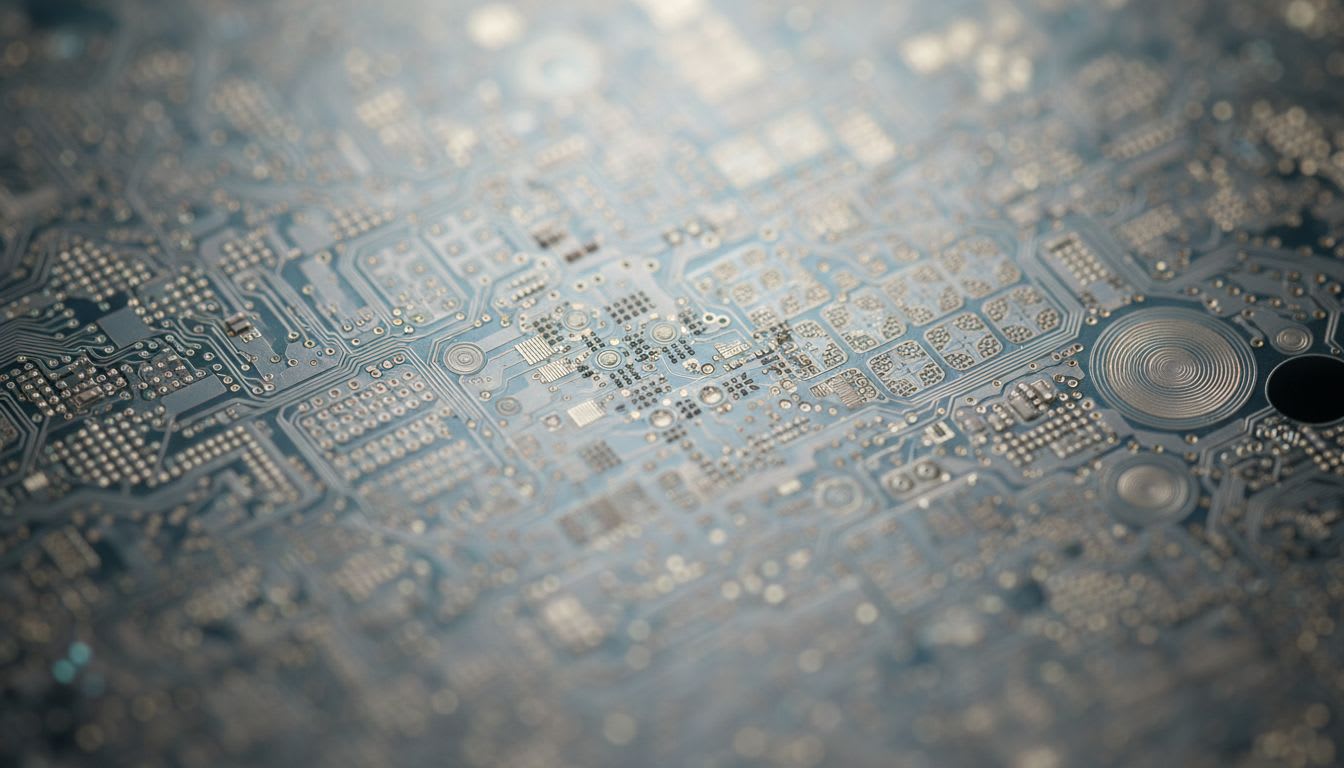

Automating a semiconductor production line goes far beyond merely replacing human hands with robotic arms or machines. It involves addressing the fundamental requirements of ultra-fine semiconductor processes, which demand nanometer-level precision, a flawless environment that permits not a single particle, and achieving consistently high-quality across millions of chips. While typical industrial automation focuses on increasing output or reducing labor, semiconductor automation targets responding to ‘invisible threats’ that could cause catastrophic defects and realizing ‘near-impossible accuracy’. Even the slightest thickness variation or unseen contamination at the nanometer scale can determine a product’s functionality and lifespan. Solving these sophisticated technical challenges is the real starting point and ultimate task of true semiconductor production line automation, and Huvics is focused on elevating production efficiency and quality through the automation of precision grinding and cleaning processes, pivotal pieces of this complex puzzle. The Ultra-Precision Grinder System and Cleaner Machine represent Huvics’ technical commitment to the era of flawless production.

Huvics’ Grinding Technology that Achieves Extreme Precision

In the semiconductor production environment, which requires nanometer precision and error-free process continuity, Huvics’ automation system goes beyond merely having machines substitute human labor. Imagine an environment where even a tiny speck of dust or a thickness error less than a thousandth of a hair strand can lead to losses worth billions. To realize ‘true automation’ under such extreme conditions, a different level of ultra-precision technology must support it. Particularly, the processes of precisely adjusting the thickness of semiconductor wafers or packaging in micron units and perfectly removing surface contamination that may occur during those processes are critical stages directly linked to the final product quality. To address these challenges, Huvics presents the epitome of ultra-precision grinding technology through the Grinder System and PKG Grinder, which process various semiconductor packages like FCBGA, WLCSP, QFN/DFN, and Solar Cells to micron unit thicknesses, meeting customer requirements without errors. Using precision stages and diamond wheels, these systems not only match thickness but also maximize subsequent process stability and enable flexible production line configurations.

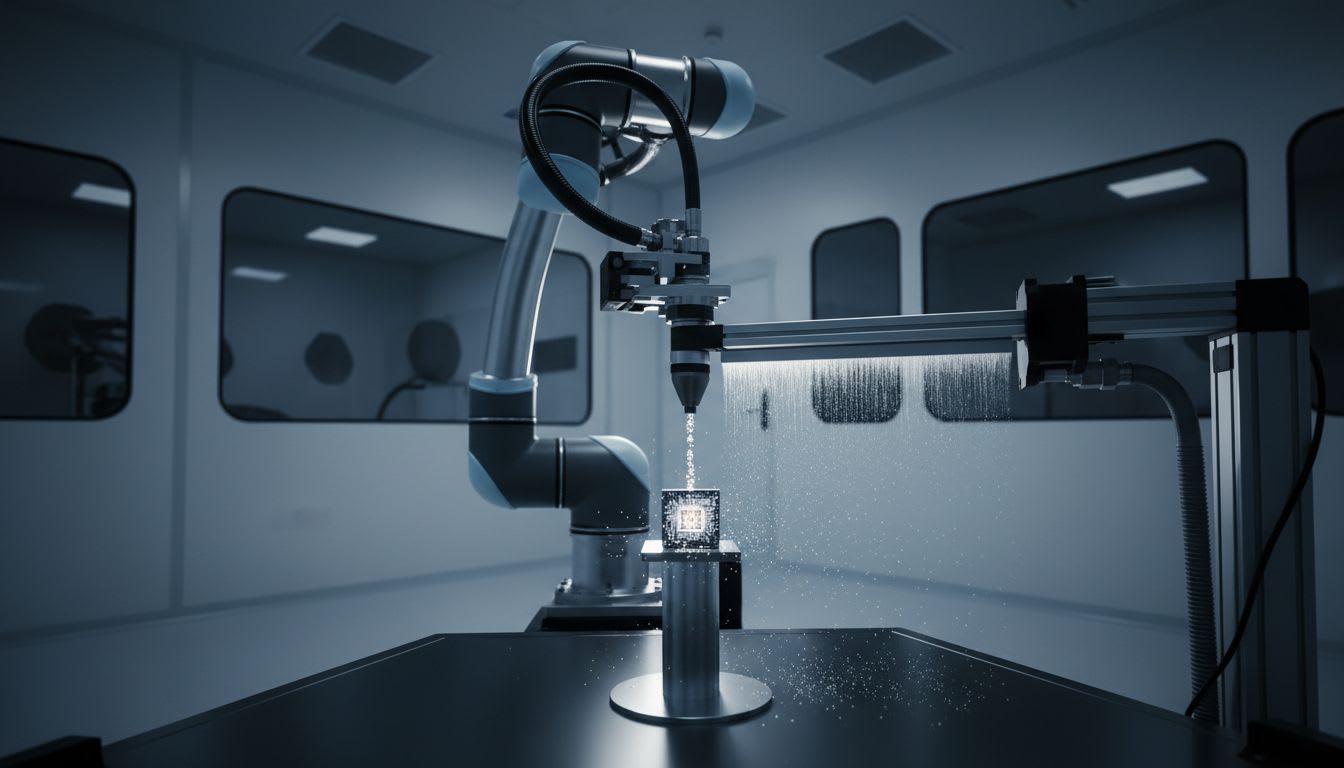

Huvics’ Perfect Cleaning Solution for Quality Stability

The ultimate goal of semiconductor production line automation is not merely speeding up production but ensuring the ‘quality stability’ of the final products. Given the semiconductor manufacturing process’s characteristics, where even a single fine contaminant particle or slight machining error can result in final product defects, precision grinding and cleaning processes are the core of automation processes and crucial determinants of semiconductor quality. Huvics offers automated equipment fully compatible with these advanced demands and sets new standards for production quality. Huvics’ precision grinding technology guarantees error-free perfect results by uniformly and precisely processing various packages to the micron thickness desired by customers. Additionally, the Cleaner Machine integrates multi-stage cleaning technologies, such as Micro Bubble, Water Jet, and Air Knife, and perfect Oven Dry functions to completely eliminate fine contaminants from the product surface, thereby significantly reducing defect rates. The synergy of these two core technologies ensures consistent top-level quality stability across all products, directly tying to production line efficiency, enhancing the company’s market competitiveness.

Huvics Automation Solution: Synergy of Production Efficiency and Quality

Key Solution Components

In conclusion, Huvics’ semiconductor production line automation solution focuses not only on providing individual equipment but also on simplifying the complexity of the entire process to realize the value of high-quality automation sought by customers. Huvics’ automation solution provides the following key features:

- Grinder System: Processes various semiconductor packages without error to micron precision using ultra-precision grinding technology

- Cleaner Machine: Removes fine contaminants and significantly reduces defect rates with multi-stage cleaning and perfect drying functions

Flexible Systems and Partnerships

These two systems are flexibly configured in Full Auto and Manual Types, enabling process automation and maintenance optimized for the customer’s production environment. Through the synergy of precision grinding and perfect cleaning technology, Huvics tackles the challenges facing semiconductor production lines and stands as a reliable partner helping customers consistently present top-quality to the market, contributing to the sustainable development of the semiconductor industry.

Ultimately, semiconductor production line automation is a technology-intensive journey towards flawless production with extreme precision where even nanometer errors are not tolerated. The ultra-precision grinding and cleaning technologies presented by Huvics solve these challenges and become the key to perfectly protecting the quality of the final product from invisible threats. This will be an essential driving force for maximizing production efficiency and elevating corporate competitiveness to a new level. It is no exaggeration to say that the sustainable future of the semiconductor industry relies on perfect control in these ‘invisible areas.’

Huvics is a cutting-edge technology company developing and manufacturing automation equipment and production systems across the semiconductor, LED, Mobile, and Cosmetic industries.

We support our customers’ productivity improvement and quality competitiveness with the best workforce and continuous technological innovation.

Contact Huvics Co., Ltd.

Phone: 031-374-8285

Email: cdpark@huvics.com