In the past, semiconductors were content with basic functional operation, but today, they have evolved to require nanometer-level precision. In this advanced process, unseen material defects, residual contamination, or trace amounts of moisture have emerged as ‘unexpected variables’ that can lead to critical defects. Now, managing these variables flawlessly from the initial to the final stage has become essential in semiconductor production and is a critical factor for stable, high-quality product output.

Preventing Material Defects with Ultra-Precision Grinding Technology

The Risk of Material Defects

The critical defect variables in semiconductor processes usually begin with unseen micro-defects. The imperfect physical foundation of the material is the biggest threat to the stability of subsequent processes. If the initial wafer has uneven thickness or a rough surface, it acts like building a structure on unstable ground, potentially compromising the final product’s performance no matter how precise the subsequent steps are.

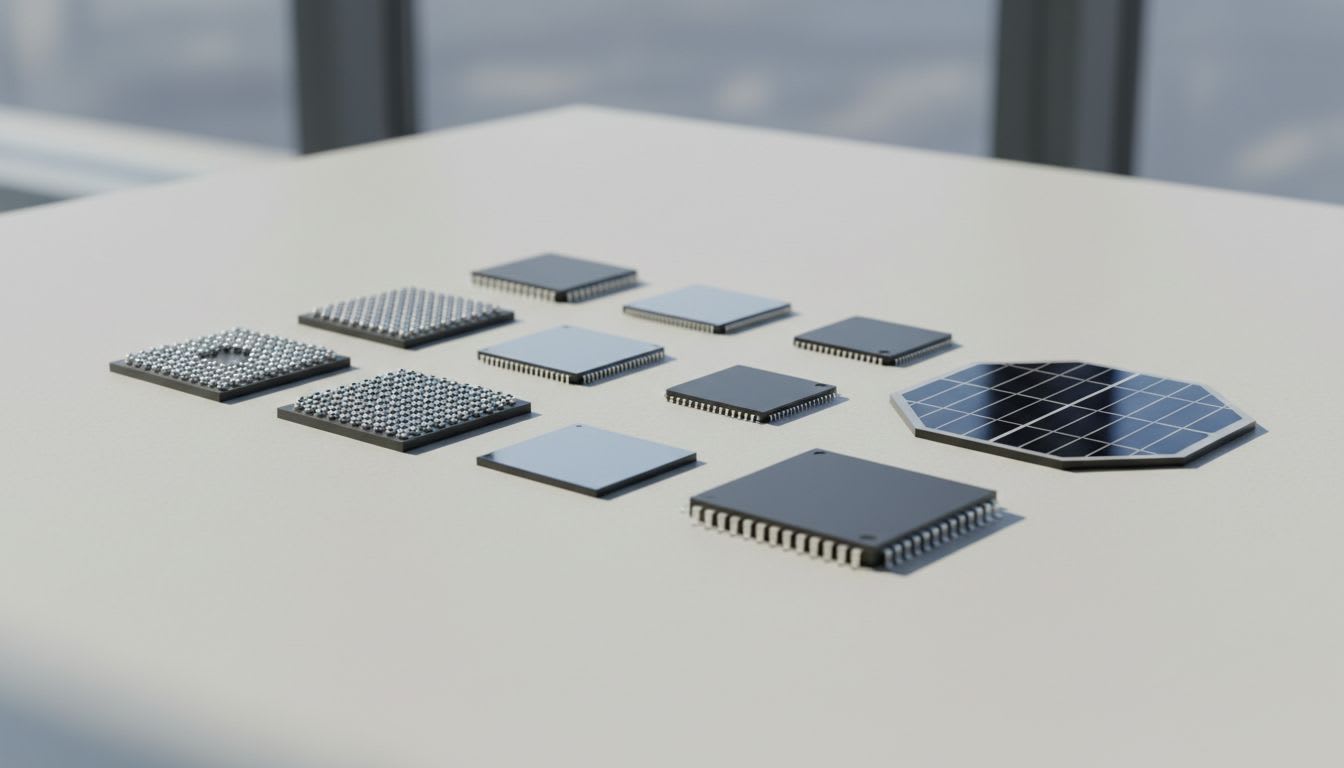

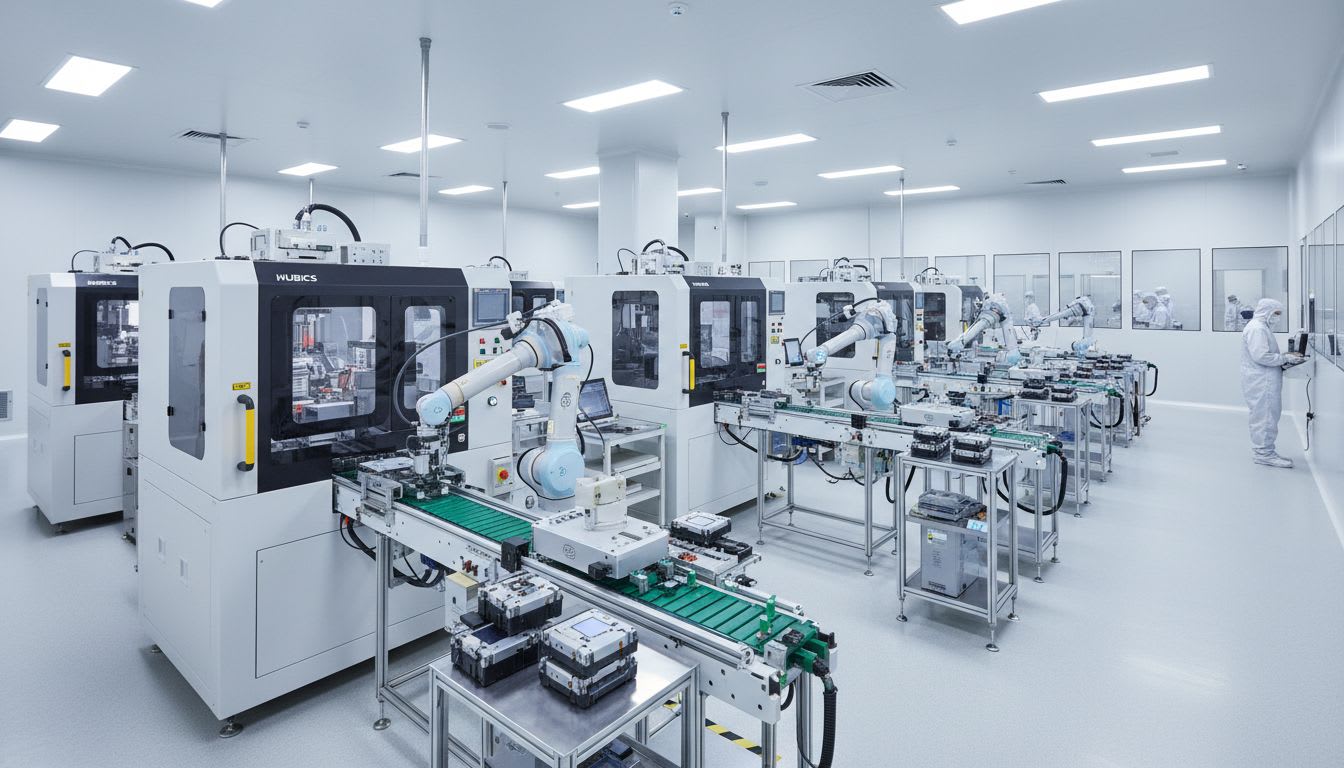

Precision Grinding of the Grinder System

Huvics focuses on establishing a perfect physical foundation for materials to fundamentally block these unseen threats. Huvics’ high-precision grinding equipment, the Grinder System, is based on ultra-precision grinding technology that does not allow micron-level errors. This system is flexibly configurable with Full Auto and Manual Types and processes various semiconductor packages such as FCBGA, WLCSP, QFN/DFN, and Solar Cell to meet the customer’s required thickness with uniformity and precision. The combination of high-precision Stages and Diamond Wheels perfectly prevents uneven thickness or surface roughness of the initial wafer from becoming unpredictable variables in subsequent processes that compromise final product performance, thus reinforcing the stability of the entire semiconductor process from the initial stages by eliminating potential defect factors in advance.

Multi-Stage Cleaning Solution for Removing Micro-Contaminant Particles

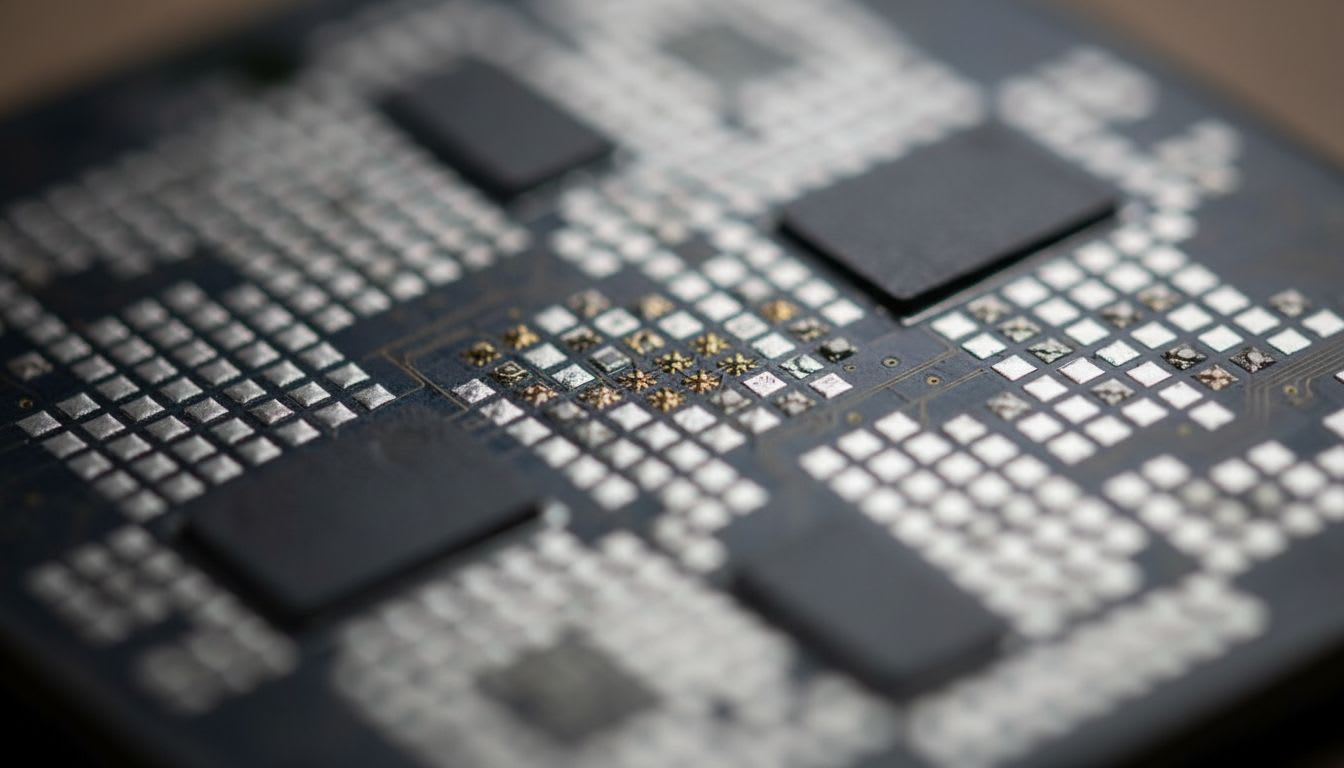

The Threat of Micro-Contaminant Particles

Even a perfectly processed wafer can harbor micro-contaminant particles on its surface, potentially sowing the seeds for other variables. Unseen, they often degrade circuit performance and undermine the final product’s reliability. The second stage of Huvics’ semiconductor defect management focuses on thoroughly removing these residual contaminants. Micro-contaminant particles or organic matter can catastrophically damage semiconductors, making their total removal essential.

Multi-Stage Cleaning of the Cleaner Machine

Huvics’ Cleaner Machine uses proprietary multi-stage cleaning technologies like Micro Bubbles, Water Jets, and Air Knives to thoroughly remove tiny particles from product surfaces. It effectively cleans micro-contaminants from camera modules, sensors, VCM motors, trays, and more—eliminating variables that could negatively affect electrical properties and reliability. This process goes beyond simple cleaning, supporting perfect drying with an Oven Dry function and offering adaptability with Full Auto and Manual types for any production line optimization. Thus, Huvics’ cleaner machine plays a crucial role in maximizing particle removal efficiency, significantly lowering process defect rates, and ensuring the final quality stability of semiconductor products.

Complete Removal of Residual Moisture with Oven Dry Function

The Potential Risk of Residual Moisture

The relief of successfully removing micro-contaminant particles is short-lived when faced with the unexpected threat to semiconductor process quality—tiny residual moisture post-cleaning. This unseen moisture can lead to recontamination in subsequent processes or cause unforeseen chemical reactions that drastically reduce the final product’s reliability. Just like how water spots on a clean window can distort sunlight, even a trace of moisture in semiconductor processes can result in catastrophic outcomes. Huvics’ decisive third stage to block this potential risk lies in achieving ‘perfect drying.’

Importance of the Oven Dry Function

The powerful Oven Dry function integrated in Huvics’ Cleaner Machine thoroughly dries products, completely eliminating the potential of any variables arising from moisture. This process not only removes moisture but also becomes a core step in dramatically reducing defect rates in semiconductor production lines, maximizing reliability, and stability of the final products. By meticulously managing every micro-variable that arises in each process stage, Huvics offers solutions that guarantee success in semiconductor processes. From contaminant particle removal to perfect drying, Huvics’ technology plays a vital role in enhancing production efficiency and elevating the final product’s value.

Achieving Semiconductor Process Stability through Integrated Solutions

The subtle variables in semiconductor processes decisively influence the final product quality. Since small, unseen contaminants or micro-processing errors can lead to critical defects, absolute precision in every manufacturing stage is required. Huvics offers integrated solutions that meticulously control such ‘unexpected variables’ from start to finish, guaranteeing the stability of semiconductor production lines and flawless quality of the final products.

Composition of Huvics Integrated Solution

- Perfectly establishing the physical foundation of semiconductor packages with ultra-precision grinding technology to eliminate defect causes

- Thoroughly removing micro-contaminant particles with multi-stage cleaning technology and drying them with an Oven Dry process

Value and Vision of the Solution

By seamlessly connecting key stages from precision grinding to perfect cleaning and drying, Huvics proactively eliminates all potential defect variables. Huvics’ unique technology and system flexibility in each process aim to boost client production efficiency and, ultimately, elevate the reliability and performance of semiconductor products. The comprehensive solutions offered by Huvics promise not only equipment but also a stronger future for the semiconductor industry.

The numerous unexpected variables faced in semiconductor processes start from unseen minute threats, dictating the quality and reliability of the final products. From micro-physical defects in the initial wafer to invisible contaminant particles and final residual moisture, Huvics provides integrated solutions that control all stages without fail. The series of processes, from precision grinding to perfect cleaning and drying, becomes key to maximizing the stability of semiconductor production lines and enhancing product value. This is why Huvics’ technology guarantees a fortified semiconductor future leading to customer success.

Huvics is an advanced technology enterprise specializing in the development and manufacturing of automation equipment and production systems across the semiconductor, LED, mobile, and cosmetics industries. We support improving customer productivity and securing quality competitiveness through excellent human resources and continuous technological innovation.

Contact Huvics

Phone: 031-374-8285

Email: cdpark@huvics.com